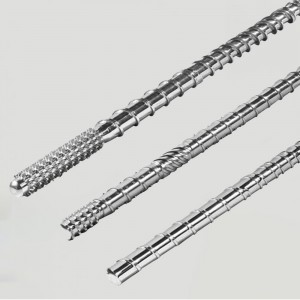

I-Single Screw Plastic Extruder

Ngokuthuthukiswa kokuqwashisa ngemvelo, ukugaywa kabusha kwepulasitiki sekuyinkinga eshisayo namuhla.I-screw extruder eyodwa idlala indima ebalulekile ohlelweni lokugaywa kabusha kwamapulasitiki.Ngokwenza kabusha imfucuza yepulasitiki, ngemva kokuncibilika nokukhishwa, ingenziwa ibe imikhiqizo yepulasitiki futhi.Lokhu akugcini nje ngokusindisa izinto zokusetshenziswa, kodwa futhi kunciphisa ukungcoliswa kwemvelo.

Isimiso sokusebenza se-screw extruder esisodwa simi kanje:

1. Ukondla: izinhlayiya zepulasitiki noma impushana yengezwa engxenyeni yokuphakelayo ye-scruder extruder ngokusebenzisa imbobo yokuphakelayo.

2. Okuphakelayo nokuncibilika: Isikulufu sizungeza emgqonyeni ukuze siphushele izinhlayiya zepulasitiki phambili, futhi sisebenzise izinga lokushisa eliphezulu nokucindezela okuphezulu ngesikhathi esifanayo.Njengoba ipulasitiki ishiswa ukungqubuzana ngaphakathi kwesikulufu nomgqomo, ipulasitiki iqala ukuncibilika futhi yakhe ukuncibilika okufanayo.

3. Ukwanda kokucindezela kanye nendawo yokuncibilika: intambo yesikulufa iba kancane kancane, yenza indlela yethrafikhi ibe mncane, ngaleyo ndlela ikhulise ukucindezela kwepulasitiki emgqonyeni, nokushisa okuqhubekayo, ukuncibilika nokuxuba ipulasitiki.

4. I-Extrusion: Emgqonyeni ongemuva kwendawo encibilikayo, isikulufu siqala ukushintsha isimo, siphushela ipulasitiki encibilikisiwe sibheke lapho kuphuma khona umgqomo, futhi siqhubeke sicindezela ipulasitiki ngembobo yokubumba yomphongolo.

5. Ukupholisa nokubunjwa: Ipulasitiki ekhishiwe ingena emanzini okupholisa ngembobo yesikhunta ukuze iphole ngokushesha, ukuze iqine futhi ibe nokulolongwa.Imvamisa, izimbobo zokufa kanye nesistimu yokupholisa ye-extruder yakhelwe ngokusho komumo womkhiqizo oyifunayo.

6. Ukusika nokuqoqwa: Ukubunjwa okukhishwe ngokuqhubekayo kukhishwa emgodini wesikhunta, bese kusikwa ubude obudingekayo, futhi kuqoqwe futhi kuhlanganiswe ngamabhande okuthutha noma amanye amadivaysi okuqoqa.

1. Ukusetshenziswa kobuchwepheshe be-automation

Ngokuthuthuka okuqhubekayo kobuchwepheshe be-automation, ama-extruder e-single-screw nawo abuyekezwa njalo.Isistimu yokulawula okuzenzakalelayo ingakwazi ukubona ukuqapha kwesikhathi sangempela kanye nokulungiswa kwesimo sokusebenza se-extruder, ithuthukise ukusebenza kahle kokukhiqiza nokuzinza kwekhwalithi.Idizayini edidiyelwe kanye nesixhumi esibonakalayo sokusebenza esihlakaniphile nakho kwenza umsebenzi ukuqonde kalula.

2. Isidingo sokuvikelwa kwemvelo okuluhlaza

Emhlabeni, isidingo sokuvikelwa kwemvelo eluhlaza siya ngokuya siphuthuma.Ama-extruder anesikulufu esisodwa azophinde athuthuke ngendlela evumelana nemvelo.Isibonelo, ukuthuthukiswa kwezinto ezisetshenziswayo zenjoloba evumelana nemvelo nezinto ezingaboli, kanye nocwaningo lokonga amandla nobuchwepheshe bokunciphisa ukusetshenziswa kuyisiqondiso sentuthuko yesikhathi esizayo.