Ama-PE amancane ama-granulator emvelo ngo-2025 asebenzisa amamotho asebenza kahle kakhulu, ukuthuthukiswa kwenqubo, kanye ne-automation yesikhathi sangempela ukusika ukusetshenziswa kwamandla. Ama-opharetha abona imiphumela esheshayo, njenge-aUkwehla ngo-40% kokusetshenziswa kwamandla ngethani ngalinyeuma kuqhathaniswa nendabukoumshini wesikulufa esisodwa or i-extruder yesikulufu esisodwaizinhlelo. Ukubuyiselwa kokushisa kwemfucuza nakho kuyasekelaumshini we-granulator ongenamanziimisebenzi.

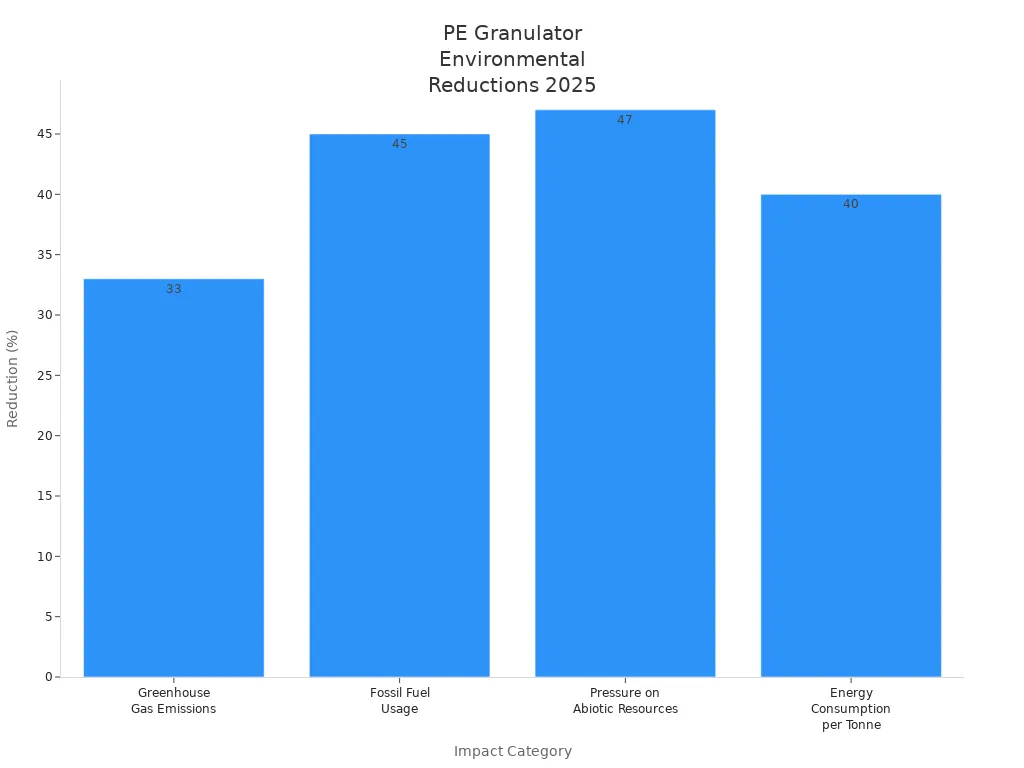

| Imethrikhi | Ukwehliswa Okuzuzwe Ngo-2025 Uma Kuqhathaniswa neminyaka edlule |

|---|---|

| Ukunciphisa Ukukhishwa Kwegesi Ebamba Ukushisa | 33% yehla |

| Ukunciphisa Ukusetshenziswa Kwezinsalela | 45% yehla |

| Ingcindezi Yezinsiza Ze-Abiotic | 47% yehla |

| Ukusetshenziswa kwamandla ngethani ngalinye | Iphansi ngokufika ku-10 kW-h/tonne, ngo-40% ngaphansi kwemishini evamile |

I-PE Small Environmental Granulators: Ubuchwepheshe Bokonga Amandla

Izinjini Ezisebenza Kakhulu Nezisetshenziswa Zokudlulisa

Ama-PE amancane ama-granulator emvelo ngo-2025 athembele kuwoamamotho asebenza kahle kakhulu kanye namadivayisi athuthukisiwe okudlulisela phambiliukuze kuzuzwe ukonga amandla okubalulekile. Lawa ma-motor aguqula amandla kagesi abe amandla emishini ngokulahleka okuncane, okuqinisekisa ukuthi amandla amaningi okokufaka ashayela inqubo ye-granulation. Imishini yokudlulisa ethuthukisiwe ithuthukisa lokhu kusebenza kahle ngokuthuthukisa indlela amandla ahamba ngayo ukusuka kumotho ukuya ezingxenyeni zokusika kanye ne-extrusion. Uma buhlangene, lobu buchwepheshe bunciphisa ukusetshenziswa kwamandla okuphelele phakathi nokusebenza. Lokhu kuhlanganiswa kwakha isu elibanzi lokonga amandla elisekela kokubili ukusetshenziswa kwamandla okuphansi kanye nokusebenza kahle kokukhiqiza okuphezulu. Abakhiqizi bayahlomula ezikweletini zikagesi eziphansi kanye nokusebenza okuthuthukisiwe kwemishini. Ukusetshenziswa kwamamotho asebenza kahle kakhulu kanye nemishini yokudlulisa kuphinde kunwebe isikhathi sempilo ye-granulator, kunciphise izidingo zokunakekela kanye nesikhathi sokuphumula.

Ithiphu:Ukuthuthukela kumamotho asebenza kahle kakhulu namasistimu okudlulisa kunganciphisa ukusetshenziswa kwamandla kufika ku-30% uma kuqhathaniswa namamodeli amadala.

I-Intelligent Automation kanye Nokuthuthukisa Inqubo

I-Automation ehlakaniphile ime emnyombweni wezimbudumbudu zemvelo zesimanje ze-PE. Lawa masistimu asebenzisa izilawuli ezihlakaniphile ukuqapha nokulungisa izinkomba zokusebenza ezibalulekile njengezinga lokushisa, isivinini semoto, nokudlidliza. Ama-opharetha angathembela kuzici ezifana nezikrini zokuthinta ze-PLC, ezivumela ukulungiswa okuguquguqukayo kumazinga okushisa nosayizi we-pellet. Izinzwa zithola izinkinga ezifana nokuvala ukufa noma ukugcwala kwemoto, ukwehlisa ingcuphe yesikhathi sokuphumula esingalindelekile.

- I-Smart granulator ilawula izinkomba zokusebenza zokulandelela ukulungiswa okubikezelwayo.

- Amasistimu asekelwe ku-AI azisa ukuhlelwa kokulungisa, njengokuthi kufanele ushintshe nini imimese noma amabheringi.

- Amapulatifomu asekelwe efwini anika amandla ukuqapha okukude futhi athumele izikhumbuzi zokulungisa.

- Izintambo zekhabhinethi yamandla zisekela ukuhlanganiswa okulula nezinye izinto zokusebenza.

- Ukuzenzakalela kunciphisa ukungenelela okwenziwa ngesandla, ukuthuthukisa ukuphepha nokuthembeka.

- Ukuthuthukiswa kwenqubo kushuna kahle amapharamitha wokusebenza, ukwenza lula imbudumbudu kanye nokunciphisa ukumosheka kwamandla.

- Idizayini ye-modular ivumela ukwenza ngokwezifiso izinto ezahlukahlukene nezidingo zokukhiqiza.

Amasu okuthuthukisa inqubo athuthukisa ukusebenza kahle kwamandla. Imiklamo yemishini edidiyelwe ihlanganisa ukucucuza, ukusika, ukukhishwa, kanye ne-pelletizing kube umsebenzi owodwa oqhubekayo. Le ndlela inciphisa ukusebenza, isikhathi, namandla. Izindlela zokuphakela ezingaguquki zinzinzisa ukugeleza kwezinto ezibonakalayo, zivimbela isikhathi sokuphumula futhi zithuthukise ikhwalithi yokuphumayo. Izici zokuzenzakalela njengokulawula ukuphakela ngokuzenzakalela, izihlungi zeziteshi ezimbili, nokulungiswa ngokuzenzakalela kwesivinini sommese kuqinisekisa ukukhiqizwa okushelelayo nokusebenza kahle. Amamotho awonga amandla, isivinini esishintshashintshayo, nezinhlelo zokupholisa ezithuthukisiwe nakho kunomthelela ekwehliseni ukusetshenziswa kwamandla.

Ukubuyisela Ukushisa Kwemfucuza kanye nokusetshenziswa

Ukubuyiselwa kokushisa kukadoti kumelela intuthuko enkulu kuma-PE ama-granulator amancane emvelo. Ngesikhathi senqubo ye-granulation, imishini ikhiqiza ukushisa njenge-byproduct. Esikhundleni sokuvumela lokhu kushisa kuphume, amasistimu esimanje ayathwebula futhi akusebenzise kabusha. Ubuchwepheshe obufana namaphampu okushisa okushisa okuphezulu namasistimu okugcina ukushisa okucashile asebenzisa izinto zokushintsha kwesigaba (ama-PCM) abuyisela ukungcola okunezinga lokushisa eliphansi lokushisa futhi akuthuthukise ukuze asetshenziswe ekukhiqizeni isitimu noma ukushisisa isikhala. Ezimbonini zemibukiso, amasistimu wephampu yokushisa eyingxube athole ngaphezu kuka-80% wokushisa kukadoti, okwehlisa ukuthembela ekushiseni kukagesi kube ngaphansi kuka-20%. Lokhu akugcini nje ngokuthuthukisa ukusebenza kahle kwamandla kodwa kuletha nembuyiselo eqinile yezomnotho, ngokuvamile ezikhokhela yona ngaphansi kweminyaka emithathu. Inhlanganisela yokugcina ukushisa kanye namaphampu okushisa yenza ukusebenza okuqhubekayo nokuguqulwa komthwalo, kuqhubeke ukusika izindleko zamandla kanye nokunciphisa ukukhishwa kwe-CO2.

| Ubuchwepheshe | Umsebenzi | Umthelela Ekusetshenzisweni Kwamandla |

|---|---|---|

| Iphampu Yokushisa Esezingeni Eliphezulu | Ithuthukisa ukushisa kwemfucuza kokucubungula isitimu | Yehlisa ukushisa kukagesi |

| I-Latent Heat Storage (PCM) | Igcina futhi ikhiphe ukushisa njengoba kudingeka | Inika amandla ukushintshwa kokulayisha |

| IHybrid System | Ihlanganisa kokubili ukusebenza kahle okuphezulu | Ibuyisa u-81.1% wokushisa kukadoti |

Amagranulator amancane emvelo e-PE asetha indinganiso entsha yokusebenza kahle kwamandla ekugayweni kabusha kwepulasitiki. Ubuchwepheshe babo obuthuthukisiwe bokonga amandla busiza abakhiqizi behlise izindleko, bathuthukise ukukhiqiza, futhi basekele imigomo yemvelo.

Izinzuzo zama-PE Small Environmental Granulators ngo-2025

Izindleko Zokusebenza Ezincishisiwe kanye Nokusetshenziswa Kwezamandla

Abakhiqizi babona ukonga kwezindleko okucacile lapho besebenzisa ama-PE ama-granulator amancane emvelo. Amamodeli apholile emoyeni asusa isidingo samanzi, okugcina imali ekuhlanzeni amanzi nasekugcinweni kwemishini. Lawa ma-granulator asebenzisa amandla amancane kunamasistimu apholiswa ngamanzi ngenxa yokwakheka kwawo okulula nokusebenza okuthuthukisiwe. Ukunakekela kuba lula, futhi ingozi yokuqhekeka kwezinkinga zesistimu yamanzi iyehla. Ama-opharetha angasebenzisa le mishini ezindaweni ezinamanzi amancane noma izinga lomoya eliphansi, okugcina ukukhiqizwa kuzinzile. Ukupholisa okufanayo kuthuthukisa ikhwalithi yomkhiqizo futhi kunciphisa imfucuza.

- Ukusebenza ngokupholiswa komoya kuqeda izindleko zamanzi kanye nokunakekelwa okuhlobene.

- Ukusetshenziswa kwamandla aphansi kusho izikweletu zikagesi ezincane.

- Isakhiwo esilula sinciphisa izidingo zokulungisa kanye nesikhathi sokuphumula.

- Ukusebenza okuzinzile ezindaweni ezinzima kuqinisekisa ukuphuma okuthembekile.

- Izinga lomkhiqizo elingcono liholela ekumosheni okuncane nokusebenza kahle okuphezulu.

Umthelela Wemvelo kanye Nokuncishiswa Kwezingqimba Zekhabhoni

Izimbudumbudu ezincane ze-PE zemvelo zisiza izinkampani zehlise umthelela wazo kwezemvelo. Banqamula ukukhishwa kwekhabhoni futhiukusetshenziswa kwamandla, okwenza ukucubungula kwepulasitiki kube luhlaza.

| Inzuzo Yezemvelo | Imininingwane |

|---|---|

| Ukunciphisa Ukukhishwa Kwe-CO2 | Amathani angu-1.5 CO2 ancishisiwe ngethani ngalinye lamapellets avuselelwe |

| Ukunciphisa Ukusetshenziswa Kwamandla | Amandla angaphansi ngo-30% asetshenziswa ama-granulator amasha anesivinini esiphansi |

| Ukunciphisa Umsindo | 20dB amazinga omsindo aphansi |

| Ukuthuthukiswa Kwezinga Lokugaya Kabusha | Ukugaywa kabusha kweluphu evaliwe kunciphisa ukusetshenziswa kwezinto ezingavuthiwe |

| Isibonelo secala - Izimoto | amathani angu-300 epulasitiki amasha alondolozwa minyaka yonke ngokugaywa kabusha kukabumper kadoti |

| Isibonelo - Ezolimo | Izinga lokuguqulwa elingu-85% elitholwe abalimi baseNdiya besebenzisa ama-pellets amancane |

Le mishini iphinde isekele umnotho oyindilinga ngokuphendula imfucuza yepulasitiki ibe yizinhlamvana ezingasetshenziswa kabusha. Le nqubo inciphisa ukulahlwa kwemfucuza futhi yonga izinsiza zemvelo.

Ukuhambisana Nokuzivumelanisa nezimo Kumazinga Omkhakha

Ama-PE amancane ama-granulators emvelo asiza izinkampani ukuthi zihlangabezane nemithetho eqinile yezemvelo ezifundeni eziningi. Imishini isekela ukugaywa kabusha kanye nokunciphisa ukusetshenziswa kwendawo yokulahla imfucumfucu, okuhambisana nezinhlelo zikahulumeni zokungalahli lutho. Amamodeli amaningi ahlangabezana nezindinganiso zamazwe ngamazwe njenge-ISCC PLUS, elandelela ukusetshenziswa kwesitoko esizinzile futhi eqinisekisa ukuhambisana nemigomo yezenhlalo nezemvelo. Idizayini yabo eguquguqukayo ifanela kokubili imisebenzi emikhulu nemincane, isiza amabhizinisi ukuthi azivumelanise nemithetho eshintshayo. Okuzenzakalelayo okuthuthukisiwe kanyeizici ezonga amandlakwenze kube lula ukulandela imithetho emisha ekukhiqizweni nomsindo. Izinkampani zaseNyakatho Melika naseYurophu zisebenzisa lezi zimbudumbudu ukuze zisekele imigomo yomnotho oyindilinga futhi zihlangabezane namazinga endawo nawomhlaba.

Amagranulator amancane emvelo e-PE azuza amandla aphezulu ngokusebenzisa imiklamo enesivinini esiphansi, izici ezenza ngokwezifiso, kanye nobuchwepheshe bokugaywa kabusha obuthuthukisiwe. Le mishini isiza izimboni zehlise izindleko, zehlise imfucuza, futhi isekele umnotho oyindilinga. Izinkampani ezikhetha lezi zimbudumbudu zithuthukisa ukusimama, zihlangabezane nemithethonqubo, futhi zidale ikusasa elihlanzekile.

FAQ

Imbudumbudu encane ye-PE yemvelo iwonga kanjani amandla?

I-granulator isebenzisa izinjini ezisebenza kahle kakhulu kanye ne-automation ethuthukisiwe. Lezi zici zinciphisa ukusetshenziswa kukagesi futhi zinciphisa imfucuza ngesikhathi sokukhiqizwa kwamapulangwe epulasitiki.

Ithiphu:Ukunakekela njalo kusiza ukugcina ukonga kwamandla kuphezulu.

Ingabe i-granulator ingakwazi ukuphatha izinhlobo ezahlukene zemfucuza yepulasitiki?

Yebo. Umshini usekela izinto ezihlukahlukene zepulasitiki. Ama-opharetha angalungisa izilungiselelo zohlobo ngalunye, aqinisekise imbudumbudu engaguquki kanye nokuphumayo kwekhwalithi.

Yikuphi ukunakekelwa okudingwa yi-granulator?

Abasebenzisi kufanele bahlole izinjini, izihlungi ezihlanzekile, futhi bahlole ama-blade okusika njalo. Izilawuli ezilula kanye nezingxenye ze-modular zenza ukunakekelwa okujwayelekile kusheshe futhi kube lula.

Isikhathi sokuthumela: Jul-17-2025