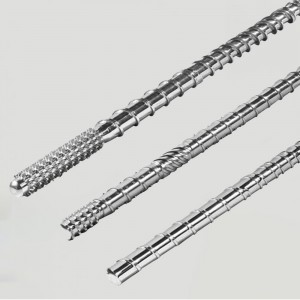

PVC Pipe screw umphongolo for extrusion

Ukwakheka kwesikulufu: Isikulufu ngokuvamile siqukethe i-shaft enentambo kanye ne-helical groove. I-shaft enentambo inesibopho sokudlulisa amandla ajikelezayo, futhi i-helical groove inesibopho sokukhipha nokuxuba izinto zepulasitiki. Idizayini yomumo wentambo kanye nephimbo izohluka ngokuya ngezidingo ezithile ze-extrusion.

Ukumelana nokushisa okuphezulu: Inqubo ye-extrusion yepayipi idinga ukumelana nokushisa okuphezulu, futhi isikulufu nomgqomo kufanele kube nokumelana nokushisa okuphezulu. Ukukhethwa kwezinto eziphezulu zensimbi ye-alloy kanye nenqubo yokwelashwa okukhethekile yokushisa kungathuthukisa ukuzinza okushisayo kwe-screw barrel.

Amandla okucindezela okuphezulu: I-Extrusion idinga ukucindezela okuphezulu okumele kufakwe ezintweni zepulasitiki, futhi umphongolo wesikulufa kufanele ukwazi ukumelana nale ngcindezi ephezulu futhi ugcine ukuqina kwesakhiwo.

Ukumelana nokugqokwa okuphezulu: Ngenxa yokuguga kwamapulasitiki nezinye izithasiselo ngesikhathi sokukhishwa, umgqomo wesikulufa kufanele ube nokumelana nokugqoka okuphezulu. Ukusetshenziswa kwezinto zensimbi ze-alloy ezingagugi kanye nobuchwepheshe obukhethekile bokwelashwa kwendawo kungathuthukisa ukumelana kwayo nokugqoka.

Okufanayo Okuphakelayo: Ngesikhathi sokukhishwa kwepayipi, ukuklanywa komgqomo wesikulufa kudinga ukuxuba okufanayo nokuncibilika kwezinto zepulasitiki. Isakhiwo sesikulufa esinengqondo kanye nomklamo womgijimi othuthukisiwe kungaqinisekisa ukufana nokuvumelana kwezinto.

Ukulawula Ukushisisa Nokupholisa: I-screw barrel ngokuvamile idinga ukulawula okunembayo kokushisisa nokupholisa ukuze kuqinisekiswe ukuzinza kwenqubo yokukhipha kanye nekhwalithi yomkhiqizo. Ukwakhiwa kwesistimu yokushisa nokupholisa kucabangela izici zezinto ezihlukene zamapayipi kanye nezidingo zenqubo ye-extrusion.

Kafushane, izici ze-tube screw barrel zihlanganisa ukumelana nokushisa okuphezulu, ukumelana nokucindezela okukhulu, ukumelana nokugqoka, ukondla okufanayo, ukulawulwa kokushisa nokupholisa, njll. Ukukhetha izinto ezifanele nokuthuthukisa umklamo yizici ezibalulekile zokuqinisekisa ikhwalithi nokusebenza kahle kokukhiqizwa kwepayipi extrusion.

Material: Insimbi ye-alloy yekhwalithi ephezulu efana ne-38CrMoAlA noma i-42CrMo.

Ukuqina: Imvamisa cishe ku-HRC55-60.

Ukwelashwa Kwe-Nitriding: Kufika ku-0.5-0.7mm ukujula ukuze kuthuthukiswe ubulukhuni bobuso nokumelana nokuguga.

I-Screw Diameter: Inqunywa ubukhulu bephaneli ethile, ububanzi, kanye nezidingo zokukhiqiza.

I-Screw Coating: Ukuzikhethela kwe-bimetallic noma i-chromium plating eqinile ukuze kukhule ukuqina.

Ukushisisa Kwemigqomo: Ukushisisa ngogesi noma amabhande okushisa e-aluminium anokulawula izinga lokushisa kwe-PID.

Isistimu Yokupholisa: Ukupholisa amanzi ngokulawula izinga lokushisa ukuze kugcinwe izinga lokushisa elifanele lokusebenza.

I-Screw Structure: Idizayinelwe nge-pitch efanelekile kanye nesilinganiso sokuminyanisa ukuze kukhishwe kahle.