Umphongolo we-screw molding screw barrel umi enhliziyweni yayo yonke inqubo yokubumba. Lapho bekhetha eliphezuluI-Plastic Machine Screw Barelnoma aI-Plastic Twin Screw Extruder Barel, abakhiqizi babona ukugeleza kwempahla okushelelayo, amaphutha ambalwa, nezindleko eziphansi.I-Stainless Steel Twin Screw Extruder Barrelizinketho zibuye zisize ukunweba impilo yemishini kanye nokunciphisa isikhathi sokuphumula.

Izindima Ezibalulekile Zomjovo Wesikulufu Wokubumba Umjovo Wepulasitiki

Ukuncibilika kanye ne-Homogenizing Plastic Material

Umgqomo wesikulufu sokubumba umjovo wepulasitiki udlala indima enkulu ekuguquleni ama-pellets epulasitiki aqinile abe into ebushelelezi, encibilikisiwe. Ngaphakathi emgqonyeni, isikulufu siyazungeza futhi siphushele ama-pellets phambili. Njengoba ama-pellets enyakaza, amabhande e-friction kanye ne-heater ayawancibilikisa. Umgqomo ugcina ukushisa kulingane, ngakho ipulasitiki iyancibilika ngenani elifanele. Le nqubo isiza ukugwema izigaxa noma izindawo ezibandayo endabeni.

Ithiphu: I-screw barrel inezindawo ezintathu eziyinhloko—okuphakelayo, ukuminyanisa, nokukala. Indawo ngayinye inomsebenzi okhethekile. Indawo yokudla iyanyakaza futhi ishisa kuqala ama-pellets. Indawo yokucindezela incibilikisa ipulasitiki futhi isuse umoya. Indawo yokukala yenza isiqiniseko sokuthi inyibiliko ibushelelezi futhi isilungele ukujova.

| Indawo | Imisebenzi Eyisisekelo |

|---|---|

| Indawo yokuphakelayo | Ihambisa ama-pellets, iwashise kuqala, futhi ihlanganiswe ukuze ikhiphe amaphakethe omoya. |

| Indawo Yokucindezela | Incibilikisa ipulasitiki futhi isuse umoya ngokucindezela nokushear. |

| I-Metering Zone | I-Homogenizes ukuncibilika, kwakha ingcindezi, futhi kuzinzise ukugeleza komjovo. |

Ukulawula izinga lokushisa kubaluleke kakhulu. Isibonelo, i-UPVC eqinile idinga ukushisisa ngokucophelela phakathi kuka-180-190°C. I-screw barrel isebenzisa kokubili izifudumezi zangaphandle kanye nokunyakaza kwesikulufu ukuze udale inani elilungile lokushisa. Le bhalansi igcina ipulasitiki ingashi noma inamathele. Ijubane lesikulufu liphinde libe nomthelela ekutheni ipulasitiki incibilika kanjani. Uma isikulufu siphenduka kancane kakhulu, ukuncibilika kungase kungashisi ngokwanele. Uma iphenduka ngokushesha kakhulu, ipulasitiki ingashisa kakhulu. Umphongolo we-screw molding screw barrel uqinisekisa ukuthi ukuncibilika kulungile kukho konke ukudubula.

Ukuxuba Izithasiselo kanye Nokuqinisekisa Ukuvumelana Kombala

Abakhiqizi bavame ukwengeza ama-colorants noma izithasiselo ezikhethekile kumapulasitiki. Umphongolo we-screw molding screw barrel uxuba lezi zithako zibe yincibilika. Idizayini yesikulufu, enezigaba ezikhethekile zokuhlanganisa, isiza ukuhlanganisa yonke into ngokulinganayo. Lokhu kuhlanganisa kumisa ama-streaks noma amabala ukuthi angaveli emkhiqizweni wokugcina.

Ukungaguquguquki kombala kungaba nzima. Kwesinye isikhathi,izingulube ezomile zinamathela ngaphakathi kwe-hopper noma zingahlangani kahle. Umswakamo ungangcolisa i-resin nekhwalithi ye-pigment. Ukulinganisa okunembile kwama-colorants kubalulekile. Imishini isebenzisa izixube zegravimetric ukukala inani elifanele. Idizayini yesikhunta futhi isiza ukugcina imibala ngisho nasezinxenyeni ezihlukene.

Qaphela: Imiklamo ethuthukisiwe yesikulufu, njengesivimbelo noma izikulufi ze-Maddock, ahlukanisa izigaxa futhi asabalalise imibalabala kangcono. Le miklamo canthuthukisa ukusebenza kahle kokuxuba ngamaphesenti angaphezu kuka-20 futhi unciphise amanani okulahlwa afika ku-30%. Ukuhlanzwa okuvamile nokunakekelwa kugcina umgqomo wesikulufu usebenza kahle kakhulu, ukuze imibala ihlale iyiqiniso ukusuka kunqwaba iye kwelinye.

Ukudlulisa nokujova iPlastiki Encibilikisiwe

Uma ipulasitiki isincibilikile futhi ixutshwe, umphongolo wesikulufa uhambisa into encibilikisiwe ekubunjweni. Isikulufu sizungeza ngaphakathi kombhobho oshisayo, siphushela inyibiliko phambili. Uma kwakheka impahla eyanele, isikulufu sisebenza njenge-plunger. Ijova ipulasitiki encibilikisiwe esikhunjeni ngokucindezela okukhulu.

Nansi indlela inqubo esebenza ngayo:

- Amapulangwe epulasitiki angena esigabeni sokuphakelayo futhi aye phambili njengoba isikulufu siphenduka.

- Ukungqubuzana nokushisa kuncibilikisa ama-pellets.

- Isikulufu sicindezela ukuncibilika, siqinisekise ukuthi sibushelelezi futhi silingana.

- Isikulufu siyathuthuka futhi sijove ipulasitiki encibilikisiwe esikhunjeni.

Iumgqomo wesikulufa wokubumba umjovo wepulasitikiigcina yonke into ihamba kahle. Ilawula ukucindezela nokugeleza, ngakho isibhamu ngasinye sigcwalisa isikhunta kahle. Izinto eziqinile zomphongolo ziyasukuma ukuze ziguge, ziqinisekise ukuthi inqubo ihlala ithembekile ngokuhamba kwesikhathi.

Ukuthuthukisa Ukusebenza Nge-Right Plastic Injection Molding Screw Barrel

Umthelela we-Screw Geometry kanye ne-Barrel Design

Gcoba ijometriilungisa indlela ipulasitiki encibilika futhi ixutshwe ngayo ngaphakathi emgqonyeni. Ubude, umumo wentambo, ukuphakama, kanye nesivinini sesikulufu konke kudlala indima. Lapho onjiniyela belungisa le mingcele, bangakwazi ukulawula ukuthi kungakanani ukushisa nokugunda okutholwa ipulasitiki. Lokhu kusiza ekudaleni ukuncibilika okufanayo futhi kunciphisa iziphambeko ezifana nama-streaks noma amabhamuza.

Isilinganiso sokuminyanisa, esiqhathanisa ukujula kokuphakelayo kwesikulufu nezindawo zokulinganisa, sithinta indlela ipulasitiki epakishwe ngayo iqine. Isilinganiso esiphezulu sinyusa ukuminyana nokuxubana kodwa singase singafanelani namapulasitiki angezwani nokushisa. Ingcindezi yasemuva nayo ibalulekile. Iphusha inhlaka encibilikisiwe kakhulu, ihlephule izingcezu ezingancibilikisiwe futhi ithuthukise ukuxutshwa. Kodwa-ke, ukucindezela okukhulu emuva kungalimaza izinto ezithambile.

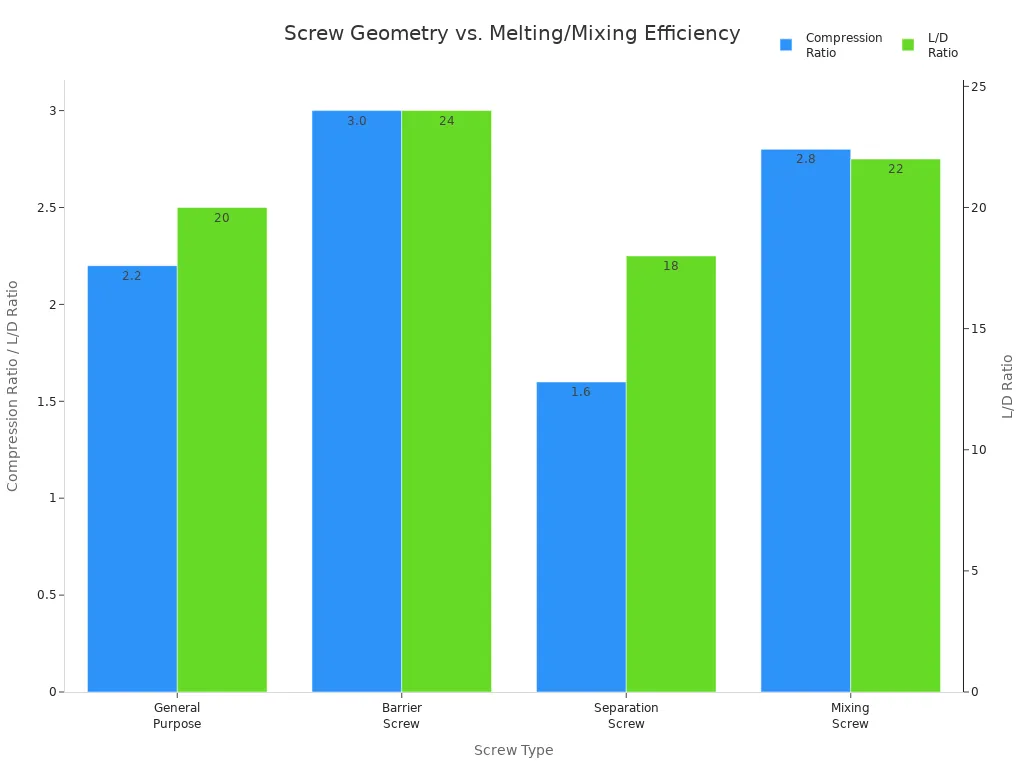

Nali ithebula elibonisa ukuthi izinhlobo ezihlukene zezikulufu kanye nejiyomethri yazo zikuthinta kanjani ukuncibilika nokusebenza kahle kokuxuba:

| Uhlobo Lwesikulufa | Izinto Ezifanelekayo | Isilinganiso sokucindezela | Isilinganiso se-L/D | Ukusetshenziswa Okuvamile | Umthelela Ekuncibilikeni Nokuxuba Ngempumelelo |

|---|---|---|---|---|---|

| Inhloso Ejwayelekile | ABS, PP, PE | 2.2:1 | 20:1 | Izindlu zikagesi | Ukuncibilika okuguquguqukayo nokuxubana nokugunda okumaphakathi nokufana. |

| I-Barrier Screw | PA+GF, PC | 3.0:1 | 24:1 | Izingxenye Zesakhiwo | Ukugunda okuphezulu nokuxuba, ukuncibilika okungcono kwe-homogeneity kanye nekhwalithi yomkhiqizo. |

| Separation Screw | I-PVC, i-POM | 1.6:1 | 18:1 | Amapayipi, Izingxenye | Ilawula ukugunda, inciphisa ukuwohloka, iqinisekisa ukuncibilika okungaguquki. |

| Ukuxuba Isikulufa | PMMA, PC+GF | 2.8:1 | 22:1 | Amakhava Akhanyayo | Ukuxuba okuthuthukisiwe, ukuncibilika okufanayo, izakhiwo ezithuthukisiwe ze-optical. |

Onjiniyela bavame ukusebenzisa amashadi ukuze baqhathanise i-screw geometry. Ishadi elingezansi libonisa ukuthi isilinganiso sokucindezela kanye nesilinganiso se-L/D sihluka kanjani ezinhlotsheni ezihlukene zezikulufu:

I-Plastic Injection molding screw barrel eklanywe kahle enejiyomethri efanele iqinisekisa ukufakwa kwepulasitiki okuzinzile, izinga lokushisa elingaguquki lokuncibilika, nokugeleza kwezinto ezibushelelezi. Lokhu kuholela ekucwebezeleni okungcono, amaphutha ambalwa, nezingxenye ezibunjiwe eziqinile.

Ukukhetha Okubalulekile Kokuqina Nokumelana Nokugqoka

Ukukhetha izinto ezifanele ze-screw barrel kwenza umehluko omkhulu ekutheni ihlala isikhathi esingakanani nokuthi isebenza kahle kangakanani. Abakhiqizi basebenzisa izinsimbi eziqinile kanye nama-coatings athuthukisiwe ukulwa nokuguga nokugqwala. Isibonelo, insimbi engu-38CrMoAlA nitrided isebenza kahle emisebenzini evamile, kuyilapho insimbi yethuluzi le-SKD61 (H13) iphatha ama-resin obunjiniyela aqinile. Imiphongolo ye-Bimetallic ene-tungsten carbide noma i-nickel-based alloys inikeza ukumelana okuphezulu kakhulu nokuhuzuka namakhemikhali.

| Uhlobo Lwezinto | Gqoka Ukumelana | Ukumelana Nokugqwala | Ukuqina Okuvamile | Amaphuzu avelele ohlelo |

|---|---|---|---|---|

| 38CrMoAlA Nitrided Steel | ★★★☆☆ | ★★☆☆☆ | ~1000 HV (I-Nitrided) | Ithembekile ezinhlelweni zokusebenza ezijwayelekile |

| Insimbi Yensimbi ye-SKD61 (H13). | ★★★★☆ | ★★★☆☆ | 48–52 HRC | Ama-resin wobunjiniyela aqinile, ukucindezeleka okushisayo |

| I-Bimetallic Barrels | ★★★★★ | ★★★★☆ | 60–68 HRC | Abrasive, fiberglass, flame retardant, plastic recycled |

Ezinye izinketho ezidumile zihlanganisa i-AISI 4140 kanye nezinsimbi ezingu-4340 zealloy ezisetshenziswa ngokujwayelekile, izinsimbi ze-D2 ne-CPM zamapulasitiki abrasive, kanye ne-Hastelloy noma i-Inconel yezindawo ezigqwalile. Ukwelapha okungaphezulu okufana ne-nitriding ne-chromium plating kuthuthukisa ubulukhuni nempilo yokuphila. Lapho abakhiqizi bekhetha impahla efanele, banciphisa isikhathi sokuphumula kanye nezindleko zokuyilungisa, bagcine ukukhiqiza kusebenza kahle.

Ithiphu: Imiphongolo ye-Bimetallic enokuqukethwe okuphezulu kwe-tungsten carbide ihlala isikhathi eside, ikakhulukazi uma icubungula ama-polymer abrasive noma agcwele.

Ukufanisa i-Screw Barrel namaPlastiki Ahlukene

Akuwona wonke amapulasitiki aziphatha ngendlela efanayo ngesikhathi sokubunjwa. Uhlobo ngalunye ludinga idizayini ye-screw barrel ethile ukuze uthole imiphumela engcono kakhulu. Onjiniyela babheka izinga lokushisa elincibilikayo lepulasitiki, i-viscosity, nokuzinza kwayo. Afanisa i-screw geometry, ukujula kwe-groove, nama-barrel coatings nezidingo zezinto ezibonakalayo.

Isibonelo, i-polycarbonate (i-PC) idinga isikulufu eside esinesilinganiso sokucindezela kancane kancane kanye nesigaba sokuxuba ukuvimbela ukuwohloka. Inayiloni (PA) idinga isikulufu esiguquguqukayo esinesilinganiso sokuminyanisa okuphezulu kanye negebe elincane phakathi kwesikulufu nomgqomo ukuze ulawule ukugunda. I-PVC idinga umphongolo ongagqwali kanye nesikulufu esigundayo ukuze igweme ukushisisa nokwakheka kwezinto.

| Uhlobo Lwepulasitiki | I-Screw Design Parameters | Umthelela Kukhwalithi |

|---|---|---|

| I-Polycarbonate (PC) | Isilinganiso esikhulu se-L/D (~26), isikulufu esihamba kancane, isilinganiso sokucindezela ~2.6, isigaba sokuxuba | I-plasticizing enhle, ivimbela ukuwohloka, ithuthukisa i-homogeneity |

| Inayiloni (PA) | Isikulufa se-Mutant, i-L/D 18-20, isilinganiso sokucindezela 3-3.5, igebe elincane | Ivimbela ukushisa ngokweqile, ilawula ukugunda, igcina ikhwalithi yokuncibilika |

| PMMA | Isikulufu esihamba kancane, L/D 20-22, isilinganiso sokucindezela 2.3-2.6, indandatho yokuxuba | Ukuncibilika okunembile, kuvimbela izinkinga zomswakama, kugcina ukunemba |

| I-PET | I-L/D ~20, isikulufu se-shear esiphansi, isilinganiso sokuminyanisa 1.8-2, ayikho indawo yokuxuba | Ivimbela ukushisa ngokweqile, ilawula ukugunda, ifanele izinto ezigaywe kabusha |

| I-PVC | Isikulufu se-shear esiphansi, umphongolo ongagqwali, L/D 16-20, ayikho indandatho yesheke | Ivimbela ukushisa ngokweqile nokugqwala, ukulawula izinga lokushisa okuzinzile |

Ukufanisa umgqomo wesikulufu wokubumba wePlastiki nohlobo lwepulasitiki kusiza ukugwema amaphutha afana nokushintsha kombala, ukuncibilika okungaphelele, noma ukugoqa. Iphinde ithuthukise izikhathi zomjikelezo kanye nokusebenza kahle kwamandla.

Qaphela: Ukuthuthukisa imiphongolo yesikulufu kumapulasitiki athile kungakhuphula izinga lokuphuma kwamanzi kuze kufike ku-25% futhi kunciphise amaphutha, konga isikhathi nemali.

Amathiphu Okunakekela Ukuphila Isikhathi Eside Nokwethenjelwa

Ukunakekelwa okuvamile kugcina umgqomo wesikulufu usebenza kahle kakhulu. Ama-opharetha kufanele ahlole umgqomo ukuthi awugugile, awuklwebhekile, noma uyakhala noma yinini lapho kukhishwa isikulufu. Ukuhlanza ngezinhlanganisela zokuhlanza ezentengiselwano kususa izinsalela futhi kuvimbela ukunqwabelana kwekhabhoni. Ukuqapha ukucindezela, izinga lokushisa, nesivinini sesikulufa kusiza ukubona izinkinga kusenesikhathi.

Nawa amanye amathiphu okunakekela asebenzayo:

- Hlola i-screw barrel ngokuyibona kanye nama-gauge njalo lapho kukhishwa isikulufu.

- Hlanza umgqomo masonto onke ukuze ugijime ngokuqhubekayo, noma njalo ezinsukwini ezingu-2-3 uma ushintsha amapulasitiki njalo.

- Gcoba izingxenye ezihambayo nsuku zonke futhi uzigcobe masonto onke ngamafutha ekhwalithi ephezulu.

- Sebenzisa izinto ezingavuthiwe futhi uzigcine ngendlela efanele ukuze ugweme ukungcoliswa.

- Qeqesha abaqhubi ukuthi babone izimpawu zokuguga futhi bagcine imininingwane yokulungisa imininingwane.

- Izingxenye ezisele zesitoko ukuze unciphise isikhathi sokuphumula.

- Ngemva kokuvala shaqa, sebenzisa isikulufu ngesivinini esiphansi ukuze usabalalise ipulasitiki eyinsalela, hlanza ngezinto zokuhlanza ezikhethekile, futhi usebenzise uwoyela ovikelayo.

I-Callout: Imiphongolo ye-Bimetallic ene-iron-based liners ingahlala isikhathi eside ngokuphindwe kathathu kunezikulufu ezijwayelekile.Ukuqondanisa kahle kanye nokugcobaandise ubude bempilo futhi unciphise imvamisa yokulungisa.

Umgqomo wesikulufu wokubumba wePlastiki ogcinwe kahle uletha ikhwalithi engaguquki, wehlisa isikhathi sokuphumula, futhi usekela ukukhiqizwa okuphumelelayo.

I-Plastic Injection molding screw barrel idlala indima ebalulekile ekuletheni ikhwalithi yomkhiqizo engaguquki kanye nokukhiqiza okuphumelelayo.

- Imiphongolo yesikulufu yekhwalithi ephezulu ithuthukisa ukungaguquguquki kokuncibilika, inciphisa izihlakala, futhi ikhulise ukusebenza kahle.

- Ukunakekelwa okuvamile kuvimbela isikhathi sokuphumula futhi kwandisa impilo yemishini.

- Ukonga izinto kanye namandla kuyengeza ngokushesha.

- Ukushintsha okusheshayo kukhulisa umthamo kanye nenzuzo.

FAQ

Yiziphi izimpawu ezibonisa ukuthi umgqomo wesikulufa udinga ukushintshwa?

Abasebenzisi baqaphela ukuncibilika okungalingani, ukwanda kokukhubazeka, noma imijikelezo ehamba kancane. Baphinde babone ukuguga okubonakalayo, imihuzuko, noma ukugoba ngaphakathi komgqomo.

Umuntu kufanele awuhlanze kangaki umgqomo wesikulufu?

Abakhiqizi abaningi bahlanza umgqomo masonto onke. Uma beshintsha amapulasitiki njalo, bawahlanza njalo ezinsukwini ezimbili kuya kwezintathu.

Ingabe i-screw barrel eyodwa ingasebenza kuwo wonke amapulasitiki?

Cha, uhlobo ngalunye lwepulasitiki ludinga umklamo othize womgqomo wesikulufa. Ukusebenzisa okufanayo okulungile kuthuthukisa ikhwalithi yomkhiqizo futhi kunciphisa ukumosha.

Isikhathi sokuthumela: Aug-15-2025