Uma ngisebenza ngomphongolo wesikulufa wePlastiki Umjovo wokubumba, ngibona indlela ukwakheka kwawo okulolonge ngayo zonke izingxenye esizenzayo. Izifundo zokulingisa zibonisa ukuthi ngishoizinguquko ezincane kusivinini sesikulufanoma izindawo zokucindezelwa zingakhuphula izinga nokusebenza kahle. Ukuthi ngisebenzisa i-aI-Twin Plastic Screw Barrelnoma gijima aPlastic Extrusion Production Line, ilungeloI-Plastic Machine Screw Barelkwenza wonke umehluko.

Imisebenzi ye-Plastic Injection molding screw barrel

Uma ngibheka inhliziyo yanoma yimuphi umshini wokubumba umjovo, ngibona umphongolo wesikulufu uphakamisa konke okusindayo. Akulona nje ishubhu elinesikulufu sokuphotha ngaphakathi. Idizayini nokusebenza komgqomo wesikulufa kwakheka zonke izinyathelo zenqubo yokubumba. Ake ngihlukanise imisebenzi yayo eyinhloko nokuthi kungani ngayinye ibaluleke kangaka.

Ukuncibilika nokuhlanganiswa kwamaPolymers

Into yokuqala eyenzekayo ngaphakathi kwe-screw barrel ukuncibilika nokuxuba ama-pellets epulasitiki. Ngithela ama-pellets ku-hopper, futhi isikulufu siqala ukujikeleza ngaphakathi kombhobho oshisayo. Umgqomo unezindawo zokushisa ezihlukene, ngakho ipulasitiki ishisa kancane kancane. Iningi lokuncibilika livela ekungqubuzaneni nasekucindezelweni okudalwe isikulufu esihlikihla kuma-pellets kanye nodonga lomgqomo. Le nqubo igcina ipulasitiki ingashisi ngokweqile futhi isiza ukuthi incibilike ngokulinganayo.

- I-screw barrel iqukethe isikulufu se-helical esijikelezayo ngaphakathi kombhobho omile.

- Izifudumezi zemiphongolo zifudumeza umgqomo ngaphambi kokuthi ngiqale, ngakho-ke i-polymer inamathela futhi iqala ukuncibilika.

- Uma isikulufu sizungeza, amandla amaningi okuncibilika avela kushear phakathi kwesikulufu nodonga lombhobho.

- Idizayini yesikulufu, ikakhulukazi indlela ukujula kwesiteshi kuba kuncane esigabeni sokuminyanisa, kuphoqelela ipulasitiki engancibilikisiwe odongeni lombhobho oshisayo. Lokhu kwandisa ukuncibilika nokuxubana.

- Njengoba ipulasitiki iqhubekela phambili, i-melt pool iyakhula kuze kube yilapho konke kuncibilika. Ukugunda okuqhubekayo kuxuba ipulasitiki encibilikisiwe nakakhulu.

Ngihlale nginaka indlela ipulasitiki encibilika ngayo futhi ixubene ngayo. Uma ukuncibilika kungafani, ngibona izinkinga ezifana nama-streaks noma izindawo ezibuthakathaka ezingxenyeni zokugcina. Idizayini ye-screw barrel, kufaka phakathi yayoubude, iphimbo, nokujula kwesiteshi, kwenza umehluko omkhulu endleleni encibilika kahle ngayo futhi ixube izinhlobo ezahlukene zamapulasitiki.

Ithiphu:Amandla amaningi okushayela emgqonyeni wesikulufu—cishe ama-85-90%—angena ekuncibilikiseni ipulasitiki, hhayi nje ukuyiyisa phambili.

Ukudlulisa kanye Homogenization

Uma ipulasitiki isiqala ukuncibilika, i-screw barrel ithatha omunye umsebenzi obalulekile: ukudlulisa impahla phambili nokuqinisekisa ukuthi ifana ngokuphelele. Ngicabanga ngalokhu njengendawo "yokulawula ikhwalithi" ngaphakathi komshini. I-screw barrel ihlukaniswe izigaba ezintathu eziyinhloko, ngayinye inomsebenzi wayo:

| Isikulufa Zone | Izimpawu Ezisemqoka | Imisebenzi Eyisisekelo |

|---|---|---|

| Indawo yokuphakelayo | Isiteshi esijulile, ukujula okungaguquki, ubude obungama-50-60%. | Ihambisa ama-pellets aqinile emgqonyeni; iqala ukushisa kuqala nge-friction kanye ne-conduction; ihlanganisa izinto ezikhipha amaphakethe omoya |

| Indawo Yokucindezela | Kancane kancane kuncipha ukujula kwesiteshi, ubude obungama-20-30%. | Incibilikisa ama-pellets epulasitiki; icindezela izinto ezibonakalayo ezikhulayo; isusa umoya ekuncibilikeni |

| I-Metering Zone | Isiteshi esingashoni kakhulu, ukujula okungaguquki, ubude obungama-20-30%. | I-Homogenizes izinga lokushisa elincibilikayo kanye nokwakheka; yakha ingcindezi ye-extrusion; ilawula izinga lokugeleza |

Ngiqaphele ukuthi ijiyomethri ye-screw barrel—njengokuphakama nokujula kwendiza yesikulufu—ithinta ngokuqondile ukuthi ipulasitiki inyakaza futhi ixubene kanjani.Imiphongolo egayiwe, ngokwesibonelo, isiza ekugcineni ingcindezi iqinile futhi ithuthukise ukuthi kungakanani okubalulekile engingakwazi ukukucubungula, ngisho nangesivinini esikhulu. Uma ngifuna ukukhulisa ukuphuma, ngingase ngandise i-screw pitch noma ngisebenzise ukuvuleka okuphakelayo okukhulu. Wonke lawa ma-tweaks wedizayini asiza i-screw barrel ilethe ukuncibilika okuqinile, okufanayo ekubunjweni, okusho ukuthi kuneziphambeko ezimbalwa nezingxenye ezingaguquki.

- Ukulawula izinga lokushisa emgqonyenikubalulekile ekuncibilikeni okufanayo kanye nokusebenza kahle kwenqubo.

- Izindawo zokushisisa eziningi ezinamazinga okushisa akhuphuka kancane kancane ukuya endaweni anciphisa amaphutha futhi athuthukise izikhathi zomjikelezo.

- Ukucushwa kwesikulufa kuthuthukisa ukuhlanganisa nokudlulisa ukusebenza kahle.

Umjovo kanye Nokugcwalisa Isikhunta

Ngemuva kokuthi ipulasitiki isincibilikisiwe futhi ixutshwe, umphongolo wesikulufa ulungela umzuzu omkhulu: ukujova ipulasitiki encibilikisiwe esikhunjeni. Nansi indlela engibona ngayo inqubo yenzeka:

- I-screw barrel ithola ama-pellets epulasitiki eluhlaza kusuka ku-hopper.

- Isikulufu siyazungeza futhi siye phambili ngaphakathi komgqomo oshisayo, sincibilike, sixube, futhi sihlanganise ipulasitiki.

- Ukugunda kwemishini ngesikulufu kukhiqiza ukushisa okungqubuzanayo, kunciphisa i-viscosity yepulasitiki ukuze ikwazi ukugeleza.

- Impahla encibilikisiwe iqoqa ngaphambili kwesikulufu, yenze “ishothi” eliyinani elilungile lokugcwalisa isikhunta.

- Isikulufu sijova isibhamu esincibilikisiwe ngomfutho ophezulu kanye nesivinini esikhaleni sesikhunta.

- Isikulufu sigcina ingcindezi yokupakisha ukuqinisekisa ukuthi isikhunta sigcwala ngokuphelele futhi sinxephezela noma yikuphi ukushwabana.

- Ngemva kokugcwalisa isikhunta, isikulufu siyahoxisa ukuze silungele umjikelezo olandelayo ngenkathi ingxenye iphola.

Ngihlala ngibuka ukusebenza komgqomo wesikulufa phakathi nalesi sigaba. Uma izinga lokushisa lokuncibilika noma izinga lokugeleza lingahambisani, ngithola ukugcwaliswa kwesikhunta okungalingani noma izikhathi zomjikelezo omude. Ukusebenza kahle komgqomo wesikulufa ekuncibilikeni nasekunyakazeni ipulasitiki ngokushesha kungisiza ukuthi ngigcine izikhathi zomjikelezo zimfushane kanye nekhwalithi ephezulu. Kungakho nginaka kakhulu idizayini nesimo somgqomo wesikulufu wokubumba wePlastiki Umjovo—ilawula yonke inqubo kusukela ekuqaleni kuya ekugcineni.

I-Screw Design kanye Nomphumela Wayo Emiphumeleni Yokubumba

Ukufanisa i-Screw Geometry nezinhlobo ze-Resin

Uma ngikhetha isikulufu somshini wami, ngihlale ngicabanga ngohlobo lwe-resin engihlela ukulisebenzisa. Akuwona wonke ama-screw asebenza kahle nawo wonke amapulasitiki. Izitolo eziningi zisebenzisa izikulufu zenhloso evamile, kodwa ngibonile ukuthi lezi zingadala kanjani izinkinga ezifana nokuncibilika okungalingani kanye namachashaza amnyama kumkhiqizo wokugcina. Lokho kungenxa yokuthi amanye ama-resin adinga imiklamo ekhethekile yezikulufo ukuze agweme izindawo ezifile futhi agcine umfaniswano wokuncibilika.

- Izikulufu ze-barrier zihlukanisa ama-pellets aqinile kupulasitiki oncibilikisiwe, okusiza ukuncibilikisa okokusebenza ngokushesha futhi kwehlise ukusetshenziswa kwamandla.

- Izingxenye zokuxuba, njengezihlanganisi ze-Maddock noma ze-zig-zag, qinisekisa ukuthi izinga lokushisa elincibilikayo nombala kuhlala ngokulinganayo, ngakho ngibona izimpawu zokugeleza ezimbalwa nemigqa yokushisela.

- Amanye amadizayini ngezikulufu, njengesikulufu sokuxuba se-CRD, asebenzisa ukugeleza kwe-elongational esikhundleni sokugunda. Lokhu kugcina i-polymer ingabhidliki futhi kungisize ngigweme amajeli nokushintsha kombala.

Ucwaningo lwemboni lukhombisa ukuthi kufikela ku-80% wemishini inezinkinga zokuwohloka kwenhlaka exhumene nokwakhiwa kwezikulufu. Ngihlala ngifanisa i-screw geometry nohlobo lwe-resin ukuze ngigcine izingxenye zami ziqinile futhi zingenasici.

Imithelela Ekuncibilikeni, Ukuxuba, kanye Nekhwalithi Yokukhiphayo

Ijiyomethri yesikulufu ilolonga ukuthi ipulasitiki incibilika kanjani, ixube, futhi igeleze. Ngiqaphele ukuthi imiklamo ethuthukisiwe yesikulufu, njengezindiza ezivimbelayo nezigaba ezixutshwayo, iphusha i-polymer engancibiliki eduze kodonga lomgqomo. Lokhu kuthuthukisa ukushisa kwe-shear futhi kusiza ukuncibilika kube okufanayo.

Nakhu ukubuka okusheshayo kokuthi ama-screw geometries asebenza kanjani:

| Uhlobo lweJiyomethri yesikulufa | Ukuncibilikisa Ukusebenza kahle | Ukuxuba Ukusebenza | Ikhwalithi Yokukhiphayo |

|---|---|---|---|

| I-Barrier Screw | Phezulu | Kuphakathi | Kuhle, uma umphumela ulungile |

| Isikulufu Esinezigaba Ezintathu | Kuphakathi | Phezulu | Kuhle kakhulu ngokuxuba okufanelekile |

| I-Maddock Mixer | Kuphakathi | Phezulu | Ilungele ukufana kombala nezinga lokushisa |

Ngihlale ngihlose ukulinganisa. Uma ngiphusha ukuthola i-throughput ephezulu, ngizifaka engcupheni yokulahlekelwa i-homogeneity. Ikwesokudla isikulufa designemgqonyeni wami wesikulufu wokubumba wePlastiki ingisiza ukuthi ngigcine izinga lokushisa elincibilikayo liqinile, nginciphise amaphutha, futhi ngilethe izingxenye ezingaguquki kuwo wonke umjikelezo.

Ithiphu: Ngihlola ikhwalithi yokuncibilika ngokubheka ukufana kombala namandla engxenye. Isikulufu esiklanywe kahle senza lokhu kube lula.

Ukukhethwa Kwezinto Zomjovo Wezikulufu zePlastiki

Ukumelana Nokugqoka Nokugqwala

Lapho ngikhetha izinto zokwakha aI-Plastic Injection molding screw barrel, ngihlale ngicabanga ngendlela umsebenzi onzima ngayo. Amanye amapulasitiki anemicu yengilazi noma amaminerali asebenza njenge-sandpaper, ehlisa isikulufu nomgqomo ngokushesha. Ezinye, njenge-PVC noma ama-resin abamba ilangabi, zingagqwala kakhulu. Ngifuna okokusebenza kwami kuhlale isikhathi eside, ngakho-ke ngibheka izinto ezikwazi ukumelana nokuguga nokugqwala.

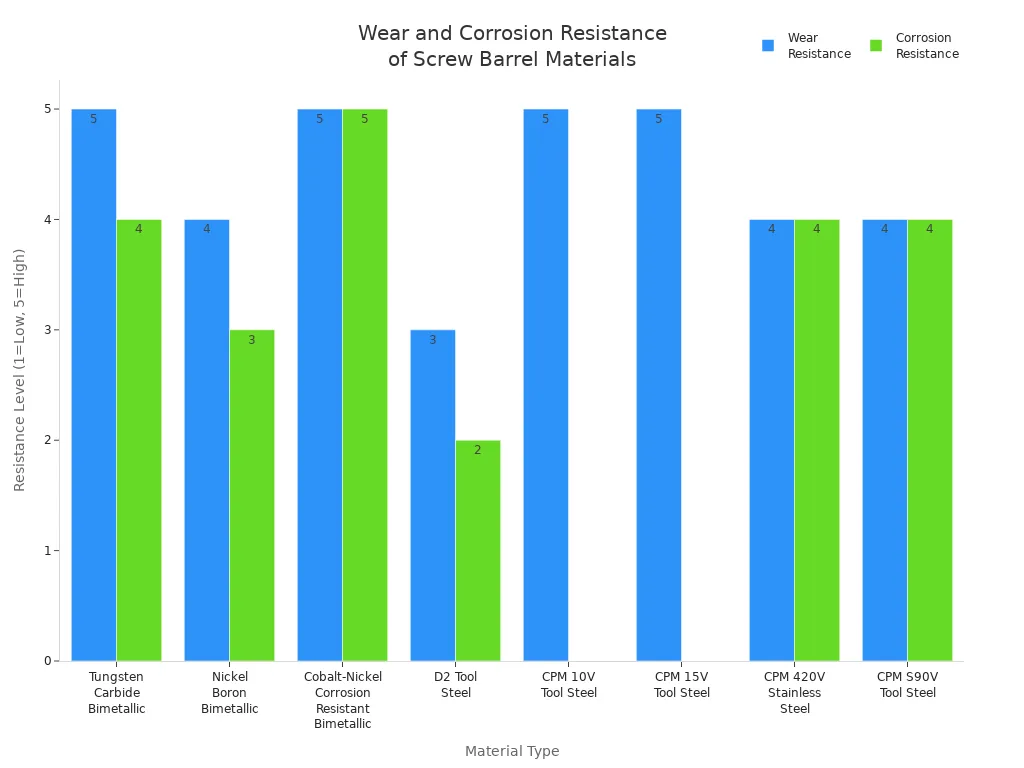

Nakhu ukubuka okusheshayo kwezinye izinketho ezijwayelekile:

| Uhlobo Lwezinto | Gqoka Ukumelana | Ukumelana Nokugqwala | Ikesi elingcono kakhulu lokusebenzisa |

|---|---|---|---|

| Insimbi ye-Nitrided | Kuhle | Impofu | Ama-resin angagcwalisiwe, angagqwali |

| I-Bimetallic Barrels | Kuhle kakhulu | Kuhle/Kuhle | Izinto ezigcwele, ezilimazayo, noma ezonakalisayo |

| Insimbi Yensimbi (D2, CPM series) | Phezulu | Okumaphakathi/Phezulu | Ingilazi/amaminerali agcwaliswe noma izithasiselo ezinzima |

| Imiphongolo Ehlanganisiwe Ekhethekile | Phezulu kakhulu | Phezulu | Ukuguga/ukugqwala okukhulu, ama-resin anolaka |

Ngibonile ukuthi ukusebenzisa imiphongolo ye-bimetallic noma izinsimbi zamathuluzi kungandisa impilo yemishini yami. Lezi zinto zimelana nokuklwebheka nokuhlasela kwamakhemikhali. Uma ngisebenzisa inhlanganisela efanele, ngichitha isikhathi esincane ekulungiseni futhi ngichitha isikhathi esiningi ngenza izingxenye ezinhle.

Ithiphu: Uma ngicubungula amapulasitiki amaningi agcwele ingilazi noma angasheshi ilangabi, ngihlala ngikhetha imiphongolo enezingubo ezithuthukisiwe noma ama-bimetallic liner. Lokhu kugcina ishejuli yami yokulungisa ibikezelwa futhi isikhathi sami sokuphumula siphansi.

Ukukhetha Izinto Zokusebenza Ze-Polymer Eqondile Nezengezo

Yonke ipulasitiki inobuntu bayo. Ezinye zimnene, kanti ezinye zilukhuni emishinini. Uma ngikhetha izinto zesikulufo sami nomgqomo, ngizifanisa namapulasitiki nezithasiselo engizisebenzisa kakhulu.

- Amafayibha engilazi namaminerali ahlafuna izinsimbi ezithambile, ngakho ngibheka ama-alloys aqinile noma ama-tungsten carbide coatings.

- Amapulasitiki abolayo, njenge-PVC noma ama-fluoropolymers, adinga imiphongolo eyenziwe ngama-alloys asekelwe ku-nickel noma insimbi engagqwali.

- Ama-resin asezingeni eliphezulu angadala ukukhathala okushisayo, ngakho ngiyahlola ukuthiisikulufu nomgqomoukwandisa ngesilinganiso esifanayo.

- Uma ngisebenzisa izinto eziningi ezahlukene, ngezinye izikhathi ngikhetha imiklamo yesikulufu se-modular. Ngaleyo ndlela, ngingakwazi ukushintsha izingxenye ezigugile ngaphandle kokushintsha sonke isikulufu.

Ngihlala ngikhuluma nomhlinzeki wami we-resin ukuze ngithole iseluleko. Bayazi ukuthi yiziphi izinto ezisebenza kangcono ngamapulasitiki abo. Ngokukhetha izinto ezifanele, ngigcina umphongolo wami wesikulufa wokubumba wePlastiki Umjovo usebenza kahle futhi ngigwema ukuphuka okungalindelekile.

Okusungulwe ku-Plastic Injection molding screw barrel Technology

Izembatho Ezithuthukile kanye Nokwelashwa Kwangaphandle

Ngibonile ukuthi ukunamathela okuthuthukisiwe nokwelashwa kwendawo kungenza umehluko omkhulu ekutheni imiphongolo yami yesikulufa ihlala isikhathi esingakanani. Uma ngisebenzisa imiphongolo ene-bimetallic linings noma ama-tungsten carbide coatings, ngibona ukuguga okuncane nokuphuka okumbalwa. Lezi zimbotshana zisiza umgqomo ukumelana nokuhuzuka nokugqwala, ngisho noma ngisebenzisa izinto eziqinile njengama-resin agcwele ingilazi. Ezinye izigqoko zisebenzisa ama-nano-materials, okusiza ngokukhipha ukushisa nokugcina inqubo izinzile. Ngiyathanda futhi ukuthi lezi zindlela zokwelapha zinciphisa ukuthintana kwensimbi kuya kwensimbi, ukuze isikulufu nomgqomo zingagayi phansi ngokushesha.

Nakhu engikufunayo kuma-coatings athuthukile:

- Ama-alloys angagugi afana nezinto engizicubungulayo

- Ukwelashwa kwendawo okubamba ukushisa okuphezulu namakhemikhali anolaka

- Izingubo ezigcina inqubo zizinzile futhi zinciphisa isikhathi sokuphumula

Uma ngikhetha i-coating efanele, ngichitha isikhathi esincane ekunakekeleni futhi ngichitha isikhathi esiningi ngenza izingxenye ezinhle. Ubuchwepheshe be-Metallurgical bubalulekile lapha. Inhlanganisela efanele ye-alloy ne-coating ingaba kabili noma kathathu impilo yesevisi yemishini yami.

Imiklamo Yangokwezifiso Yezicelo Ezikhethekile

Kwesinye isikhathi, ngidinga okungaphezu nje komgqomo wesikulufa ojwayelekile. Imiklamo yangokwezifiso ingisiza ukuxazulula izinselele eziyingqayizivele zokubumba. Isibonelo, ngisebenzise imiphongolo yesikulufu esingamawele ukuze ngithuthukise ukuxutshwa nokuphatha okushisayo. Ngiphinde ngabona izikulufu ezenziwe ngokwezifiso eziklanyelwe ukusheshisa izikhathi zokujikeleza, ukuthuthukisa ikhwalithi yokuncibilika, nokunciphisa ukugunda ngokweqile.

Ezinye izinketho engizicabangela ngemiklamo yangokwezifiso:

- Izikulufu nemiphongolo eyenziwe ngezinsimbi ezikhethekile njenge-D2 Tool Steel noma amamaki e-CPM

- Ukuqina kobuso njenge-Stellite noma i-Colmonoy ukuze kuhlale isikhathi eside

- Izindwangu zemiphongolo eziklanyelwe izinto ezithile, njengesisekelo se-nickel esine-carbide yama-polymer agcwele ingilazi

- Ama-valve ajwayelekile kanye namakepisi wokugcina anezingubo ezithuthukisiwe

Izixazululo ngokwezifiso zingivumela ngifanise okokusebenza kwami nezidingo eziqondile zenqubo yami. Lokhu kusho ikhwalithi engcono yengxenye, imijikelezo esheshayo, nesikhathi esincane sokuphumula. Ngihlala ngisebenza nethimba lokuklama eliqonda isicelo sami futhi elingaletha ubuciko bekhwalithi ephezulu.

Ukuhlonza nokuxazulula Izinkinga Zemigqomo Yesikulufu

Izimpawu Ezivamile Zokugqoka Noma Ukwehluleka

Uma ngisebenzisa imishini yami, ngihlala ngiqaphile ukuze ngibone izimpawu eziyisixwayiso zangaphambi kwesikhathi zokuthi kukhona okungahambi kahle ngomgqomo wesikulufu. Ukubona lezi zinkinga kusenesikhathi kungisiza ngigweme izinkinga ezinkulu kamuva. Nazi ezinye izinto engizibukayo:

- Izinto ezivuzayo eduze komgqomo, okuvame ukusho izimpawu ezigugile noma imvume eningi.

- Izingxenye eziphuma ezinosayizi abangahambisani noma amachashaza amnyama—lezi ngokuvamile zikhomba ekuhlanganiseni okubi noma ukungcoliswa.

- Amazinga okushisa aphezulu okusebenza, ngezinye izikhathi okubangelwa ukungqubuzana noma ukwakheka kwekhabhoni ngaphakathi komgqomo.

- Imisindo eyinqaba noma ukudlidliza ngesikhathi sokusebenza. Lokhu kungasho ukungahambi kahle, ama-bearings aphukile, noma into yangaphandle ngaphakathi.

- Izipikili zokucindezela noma ukuncibilika okungekuhle, okwenza kube nzima ukugcwalisa isikhunta kahle.

- Ukuvinjwa noma ukwakheka kwempahla ngaphakathi komgqomo, okuholela esikhathini sokuphumula nezingxenye ezimbi.

- Izinkinga zokuhlanganisa imibala noma ukungcoliswa, ngokuvamile okuvela ezintweni ezisele noma ukulawula izinga lokushisa elibi.

- Ukugqwala okubonakalayo noma umgodi, ikakhulukazi uma ngisebenzisa ama-resin abolayo.

- Izindiza eziyisikulufa ezigugile noma ulayini womgqomo, engiwubona kaningi uma ngisebenzisa izihlungi ezilumayo njengefayibha yengilazi.

- Ukuncibilika okunensayo, izinsalela eziningi, kanye nezikhathi zomjikelezo omudenjengoba imishini iguga.

Uma ngibona noma yiziphi zalezi zimpawu, ngiyazi ukuthi sekuyisikhathi sokuhlola umphongolo wesikulufu ngaphambi kokuba izinto zibe zimbi kakhulu.

Amathiphu Asebenzayo Wokuxazulula Inkinga Nokulungisa

Ukuze ngigcine imishini yami isebenza kahle, ngilandela isimiso esivamile sokuyilungisa. Nakhu okungisebenzela kangcono:

- Ngisebenzisa kuphela okokugcoba okunconywe umenzi.

- Ngibheka amazinga kawoyela we-hydraulic nsuku zonke bese ngibuyisela uwoyela ngesikhathi esimisiwe.

- Ngibuka izinga lokushisa likawoyela futhi angilokothi ngikuvumele ukuthi lishise kakhulu.

- Ngihlola amapayipi, amaphampu, namavalvu ukuthi awavuzi yini noma agugile.

- Ngihlanza futhi ngiqinise amabhande we-heater njalo ngenyanga.

- Ngisebenzisa isithombe esishisayo ukubona izinkinga zokushisisa kusenesikhathi.

- Ngiqapha izikhathi zomjikelezo, amanani okulahlwa, kanye nokusetshenziswa kwamandla ukuze ngibambe izinkinga ngaphambi kokuba zikhule.

- Ngihlala ngihlanza isikulufu kanye nomgqomo ukuze nginqande ukunqwabelana.

- Ngiqinisekisa ukuthi isikulufu sihlala siqondile futhi siqondile ngesikhathi sokufakwa.

- Ngiqeqesha ithimba lami ukuze libone izimpawu zokuqala zokuguga futhi ligcine izimo zokucubungula zizinzile.

Ukuhlala phezu kwale misebenzi kungisiza ukuthi ngigweme ukuphuka futhi ngigcine umugqa wami wokukhiqiza usebenza kahle.

Uma ngigxila kusayensi engemuva komgqomo wesikulufa sePlastiki Umjovo wokubumba, ngibona imiphumela yangempela. Ngithola izingxenye ezingcono, imijikelezo esheshayo, nesikhathi esincane sokuphumula.

- Izindleko zokunakekela eziphansi

- Ikhwalithi yomkhiqizo ethuthukisiwe

- Impilo yemishini ende

Ukuhlala ubukhali nge-screw barrel science kugcina ukukhiqiza kwami kuthembekile futhi kusebenza kahle.

FAQ

Yiziphi izimpawu ezingitshela ukuthi umphongolo wami wesikulufa udinga ukushintshwa?

Ngibona amachashaza amaningi amnyama, izingxenye ezingalingani, noma imisindo engajwayelekile. Uma ngibona lezi, ngibheka umgqomo wesikulufu ukuthi awugugile noma wonakele ngaso leso sikhathi.

Kufanele ngihlanze kangaki umgqomo wami wesikulufu?

Ngihlanza umgqomo wami wesikulufa ngemuva koshintsho lwazo zonke izinto. Ngokugijima okuvamile, ngiyayihlola futhi ngiyihlanze okungenani kanye ngeviki ukuze ngigweme ukunqwabelana.

Ngingakwazi ukusebenzisa i-screw barrel eyodwa kuzo zonke izinhlobo zamapulasitiki?

- Ngiyagwema ukusebenzisa i-screw barrel eyodwa kuwo wonke amapulasitiki.

- Amanye amapulasitiki adinga izinto ezikhethekile noma izimbotshana zokuvikela ukuguga noma ukugqwala.

Isikhathi sokuthumela: Aug-20-2025