Izimbudumbudu ezincane ze-PE zemvelo zisiza abakhiqizi banciphise ukusetshenziswa kwamandla ngezici ezihlakaniphile nobuchwepheshe obusha. Amamodeli akamuva abonisa imiphumela emangazayo:

| Imethrikhi | 2025 Ukwehliswa uma kuqhathaniswa neminyaka edlule |

|---|---|

| Ukusetshenziswa kwamandla (kW-h/tonne) | 40% ngaphansi |

| I-Greenhouse Gas Emissions | 33% ngaphansi |

| Ukusetshenziswa Kwezinsalela Zezinsalela | 45% ngaphansi |

Basebenzisaamamotho asebenza kahle kakhulu, ukubuyiswa kokushisa kukadoti, nezinhlelo zokupholisa umoya. AnImvelo Mini-Pelletizer MachinefuthiUmshini weGranulator ongenamanziuyakwazi ukuphathaI-Pvc Pelletizing Extrusionngempumelelo.

Izici Zokonga Amandla Ze-PE Small Environmental Granulators

High-Efficiency Motor Systems

Ama-PE ama-granulator amancane emvelo ngo-2025 asebenzisa ubuchwepheshe bezimoto obuthuthukisiwe ukonga amandla nokuthuthukisa ukusebenza. Le mishini incike ezintweni ezisebenza ngogesi ezinamandla asukela ku-22 kW kuya ku-110 kW, kuye ngosayizi wemodeli. Amamotho asebenza ngamakhono asuka ku-200 kuya ku-1200 kg/h, awenza afanelekele imisebenzi emincane namaphakathi yokugaywa kabusha. Ithebula elingezansi libonisa eminye imininingwane ebalulekile yobuchwepheshe:

| Ukucaciswa | Imininingwane |

|---|---|

| I-Motor Power Range | 22 kW kuya ku-110 kW |

| Uhlobo LweDrayivu | Imishini yokushayela kagesi |

| I-Axiliary Drive Power | 1.1 kW |

| Ibanga Lamandla | 200-1200 kg/h |

| Isicelo | I-PE kanye nezinye i-granulation yepulasitiki |

Lezi zinjini ezisebenza kahle kakhulu zisebenzisa ama-servo drives nezilawuli ezihlakaniphile. Zisiza opharetha ukuthi bonge amandla afinyelela ku-40% ngaphezulu uma kuqhathaniswa namamotho amadala. Ukuqapha kwesikhathi sangempela kanye ne-automation kugcina isistimu isebenza kahle, kunciphisa isikhathi sokuphumula kanye nokunciphisa izindleko zikagesi.

I-Optimized Blade kanye ne-Transmission Design

I-blade kanye nesistimu yokudlulisela kuma-PE ama-granulator amancane emvelo idlala indima enkulu ekongeni amandla. Abakhiqizi basebenzisa izindwani ezenziwe ngokwezifiso ezenziwe ngama-alloys e-premium njenge-tungsten carbide noma insimbi yesivinini esikhulu. Lezi zinto zihlala isikhathi eside futhi zisikwe ngokuphumelelayo. Nazi ezinye izindlela zokusiza ama-blades athuthukisiwe:

- Ama-engeli ama-blade anembile anciphisa umthwalo wemoto kanye nokusetshenziswa kwamandla.

- Izembatho ezithuthukisiwe, njenge-titanium nitride, ukungqubuzana okuphansi kuze kufike ku-40%.

- Ukuhlanza njalo nge-ultrasonic kugcina izindwani zibukhali futhi kuvimbela ukunqwabelana kwezinsalela.

- Ama-flat blade asebenza kangcono kumapulasitiki athambile, ehlisa ukumelana nawo futhi onga amandla.

- Izinto ezinokuqina okuphezulu zandisa umthamo wokukhiqiza ngokufika ku-30%.

Imboni yaseJalimane yokuvuselela kabusha ibone ukweqa ngo-22% ekusebenzeni kahle kanye nokwehla ngo-14% kokusetshenziswa kwamandla ngethani ngalinye ngemva kokushintshela ezintweni ezingcono ze-blade. Lapho ama-blade ehlala ebukhali futhi ehlanzekile, wonke umshini usebenza kangcono futhi usebenzisa amandla amancane.

I-Smart Automation kanye nokulawula Inqubo

I-Smart automation yenza ama-PE amancane ama-granulator emvelo asebenze kahle nakakhulu. Le mishini isebenzisa izinhlelo zokulawula ze-PLC nezikrini zokuthinta ukuze zisebenze kalula. Izici ezizenzakalelayo zifaka:

- Ukulawulwa kokuphakelayo okuzenzakalelayo kokugeleza kwezinto ezizinzile.

- Amasistimu okuhlunga amashaneli amabili avumela opharetha ukuthi bashintshe izikrini ngaphandle kokuma.

- Amasistimu okuhlunga e-back-flush okukhipha imfucuza okuzenzakalelayo.

- Ukulungiswa okuzenzakalelayo kwesivinini sommese ophehla i-pelletizing kanye nengcindezi yama-pellets afanayo.

- Ukuxazulula izinkinga ku-inthanethi kanye nokwenza kahle kwepharamitha ngokulawulwa kwamafu.

Ithiphu: I-Smart automation ayigcini nje ngokusindisa amandla kodwa futhi yehlisa isidingo somsebenzi wezandla. Ama-opharetha angagxila kweminye imisebenzi kuyilapho umshini uphatha izinguquko ezivamile.

Imiklamo ehlanganisiwe ihlanganisa ama-shredders, ama-compactor, nama-extruder abe yisistimu eyodwa. Lokhu kusetha kugcina inqubo isebenza ngaphandle kwekhefu elide, okusho ukuthi amandla amancane amoshwayo kanye nokuphumayo okuphezulu.

Ukubuyisela Ukushisa Kwemfucuza kanye nokusetshenziswa

Izicucu ezincane ze-PE azivumeli ukushisa okubalulekile kumoshe. Ngesikhathi sokusebenza, le mishini ikhiqiza ukushisa. Esikhundleni sokulahlekelwa yikho, isistimu ithwebula futhi isebenzise kabusha lokhu kushisa kwezinye izinyathelo zokukhiqiza, ezifana nezinto zokushisisa ngaphambilini noma ukufudumeza indawo yokusebenza. Le ndlela yehlisa isidingo semishini yokushisisa eyengeziwe futhi inciphisa ukusetshenziswa kwamandla sekukonke.

- Ukubuyiselwa kokushisa kukadoti kusekela izinhloso zemvelo ngokunciphisa ukukhishwa kwesisi esibamba ukushisa.

- Ukusebenzisa kabusha ukushisa kusiza abakhiqizi ukuthi bahlangabezane nezindinganiso eziqinile zamandla nemvelo.

- Inqubo iphinde igcine izindleko zokusebenza ziphansi, okwenza ama-granulator abe yi-investimenti ehlakaniphile.

Ngokuhlanganisa leziizici ezonga amandla, ama-PE ama-granulator amancane emvelo asetha indinganiso entsha yokusebenza kahle nokusimama ekugayweni kabusha kwepulasitiki.

Izinzuzo Ezisebenzayo kanye Nomphumela Wemvelo

Ukusetshenziswa Okuphansi Kwamandla Okusebenza

Ama-PE ama-granulator amancane emvelo agqama ekusebenziseni kwawo amandla aphansi. Ama-granulator amaningi endabuko, afana nomoya oshisayo noma amasistimu apholisa amanzi, asebenzisa ugesi omningi futhi adale ukungcoliswa okwengeziwe. Ithebula elingezansi libonisa ukuthi izinhlobo ezahlukene ze-granulator ziqhathaniswa kanjani:

| Uhlobo lwe-Granulator | Ukusetshenziswa kwamandla | Umthelela Wezemvelo | Amanothi Okusebenza |

|---|---|---|---|

| Ama-Granulator Epulasitiki Omoya Oshisayo Endabuko | Phezulu | Ukungcola okuphawulekayo | Ngaphezu kwama-75% wezinto zokusebenza; idinga ukuthuthukiswa |

| I-PE Small Granulator Evumelana Nemvelo | Iphansi ngenxa yokupholisa komoya nokusebenza kwezinga lokushisa eliphansi | Ukukhishwa okuncishisiwe ngenxa yokonga amandla | Isebenzisa izinsiza ezivuselelekayo futhi imoshe ukutholwa kokushisa |

| Ama-Pelletizing Systems Apholile Ngamanzi | High (amanzi nogesi) | Umthwalo wemvelo ngokusetshenziswa kwamanzi | Izinyathelo ezinkulu, ukusebenza okuyinkimbinkimbi |

| I-Slow-Speed Granulators | Phansi | Umsindo ophansi nokuguga | Ilungele izingxenye ezincane, eceleni kokusetshenziswa komshini |

| I-Heavy Duty Granulators | Phezulu | Iphakeme ngenxa yokuphuma | Okwezinto zokwakha ezinzima; ukonga amandla kancane |

Ukusebenza okupholiswe komoya, nezinga lokushisa eliphansi kusiza lawa ma-granulator asebenzise amandla amancane. Baphinde beqe isinyathelo sokumisa, esisindisa amandla engeziwe.

I-Carbon Footprint Encishisiwe kanye Nokuhambisana

Le mishini isiza izinkampani ukuthi zinciphise i-carbon footprint yazo. Basebenzisa amandla amancane futhi basebenzise kabusha imfucuza yepulasitiki endaweni, okusho ukuthi amaloli ambalwa emgwaqeni kanye nokungcola okuncane.Imishini emincane yokugaywa kabusha kwepulasitikifuthi gcina imfucuza ezindaweni zokulahla imfucuza. Ngokuguqula amapulasitiki amadala abe ama-pellets amasha, banciphisa isidingo sezinto ezintsha zokusetshenziswa. Izinkampani eziningi manje zihlangabezana nemithetho eqinile yezemvelo ngenxa yalokhu kuthuthukiswa.

Qaphela: Umenzi wezimoto waseJalimane wonga amathani angu-300 epulasitiki entsha unyaka ngamunye ngokugaya kabusha imfucuza emikhulu ngama-granulator amancane.

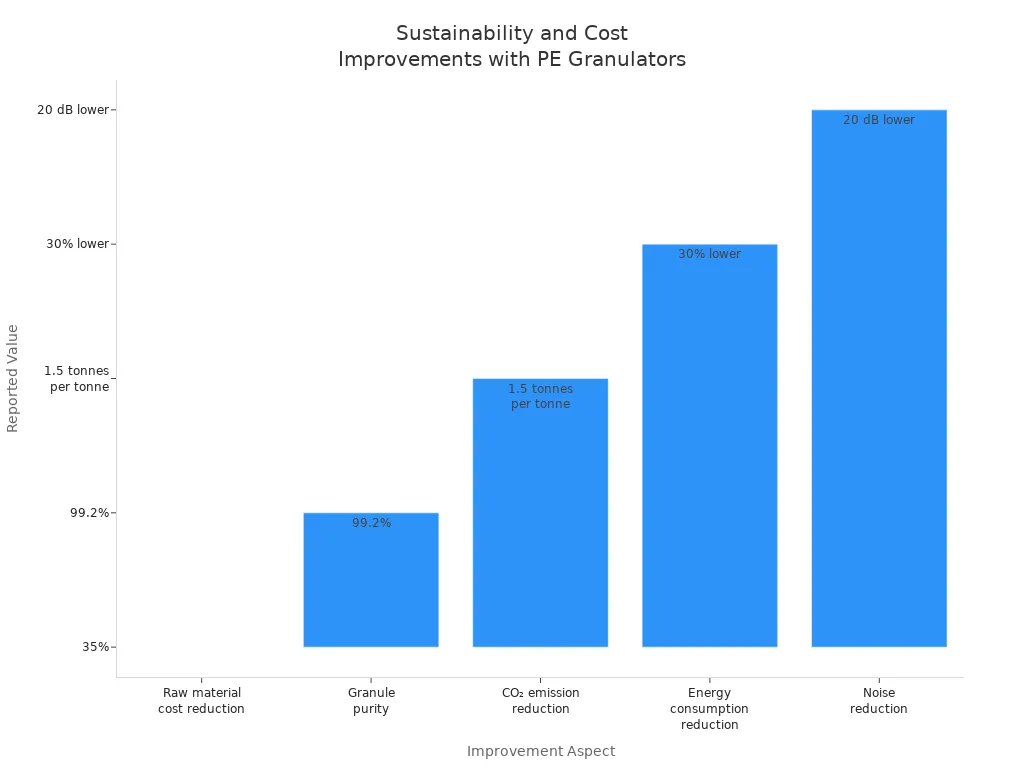

Ukonga Izindleko kanye Nempumelelo Yokukhiqiza

Abakhiqizi babona ukonga kwangempela ngalawa ma-granulator. Izinjini ezisebenza kahle kakhulu kanye ne-smart automation yehlisa izikweletu zikagesi. Umsebenzi omncane wezandla usho amaphutha ambalwa kanye nesikhathi esincane sokuphumula. Ithebula elingezansi likhombisa ukuthi kanjani aindlela ehlelekile ikhulisa ukusebenza kahle kanye nenzuzo:

| Isiteji | Incazelo | Izenzo Ezimqoka |

|---|---|---|

| Ukuhlela | Chaza izinjongo nama-KPI | Beka imigomo ye-SMART, nikeza izinsiza |

| Ukubulawa | Yenza izinguquko ku-env elawulwayo | Amaphrojekthi okulinga, linganisa ukuqeqeshwa |

| Ukuhlola | Gada inqubekelaphambili futhi uqoqe impendulo | Sebenzisa izibalo zedatha, lungisa njengoba kudingeka |

| Ukunwetshwa | Kala imikhuba eyimpumelelo | Hlanganisa izifundo ozifundile, qeqesha |

Ukwehla ngo-20% esikhathini somjikelezo kungaholela emalini engenayo eyengeziwe. Ukubuyiswa kokushisa okumoshayo nokusebenzisa amandla aphansi nakho kunciphisa izindleko.

Usayizi Ohlangene kanye Nokusebenza Kwesikhala

Idizayini ehlangene yalawa ma-granulator wonga isikhala esibalulekile saphansi. Amashabhu amancane nezikhungo zokugaywa kabusha zingazilingana ngaphandle kokushintsha isakhiwo sazo. Ama-opharetha azithola kulula ukuzinakekela futhi zihlanzekile, okusho ukuthi isikhathi sokuphumula sincane. Ukusethwa kwe-modular kusekela ukugaywa kabusha kwe-loop evaliwe, okwenza yonke inqubo isebenze kahle futhi iqhubeke.

Ithiphu: Unyawo oluncane lusho indawo eyengeziwe yezinye izisetshenziswa noma ukunwetshwa okuzayo.

Amagranulator amancane emvelo e-PE asetha indinganiso entsha yokusebenza kahle kwamandla ngo-2025. Abakhiqizi babona izinzuzo zangempela:

- Izindleko eziphansi kanye nokumosha okuncane

- Amazinga aphezulu okugaywa kabusha

- Ukusekelwa kwezinhloso zokusimama

- Ukubuyisela okusheshayo nokuhambisana okuqinile

FAQ

Imbudumbudu encane ye-PE isiza kanjani ukonga amandla?

I-granulator isebenzisa izinjini ezisebenza kahle kakhulu kanye ne-smart automation. Lezi zici zinciphisa ukusetshenziswa kukagesi futhi zigcine ukukhiqizwa kuzinzile.

Ithiphu: Izilawuli ezihlakaniphile zivumela opharetha ukuthi balungise izilungiselelo ngokushesha ukuze bathole ukonga okwengeziwe.

Ingabe ama-workshops amancane angayisebenzisa le granulator?

Yebo, bangakwazi. Usayizi ohlangene ulingana nezikhala eziqinile. Ama-opharetha akuthola kulula ukukufaka nokunakekela.

- Ilingana nemigqa yokukhiqiza emincane

- Kulula ukusebenza

Yiziphi izinto ezingenziwa inqubo ye-PE encane ye-granulator yemvelo?

IyaphathaPE namanye amapulasitiki. Umshini usebenza kahle ekugayeni kabusha imfucumfucu yepulasitiki ibe ama-pellets amasha.

| Uhlobo Lwezinto | Ifanele i-Granulation? |

|---|---|

| PE | ✅ |

| PP | ✅ |

| I-PVC | ✅ |

Isikhathi sokuthumela: Aug-14-2025