I-Conical Twin Screw Barrel ifaka idizayini ecijile ethuthukisa ukuxutshwa kwezinto kanye nokusebenza kahle kokudlulisa. Ku-extrusion yepulasitiki, iI-PVC eyi-Conical twin screw extruderuhlelo luqinisekisa ukuncibilika nokucutshungulwa kwezinto ze-PVC. Abakhiqizi abahamba phambili, okuhlanganisaI-Conical Twin Screw Extruder Barrels Factory, sebenzisa amasu okumodela athuthukile futhi anembei-tapered twin screw barrel kanye nesikulufuamapharamitha wokukhulisa ukusebenza.

| Usayizi Wemakethe 2024 | Kuhlelelwe ngo-2033 | I-CAGR (2025-2033) |

|---|---|---|

| I-USD 1.2 billion | I-USD 2.5 billion | 8.9% |

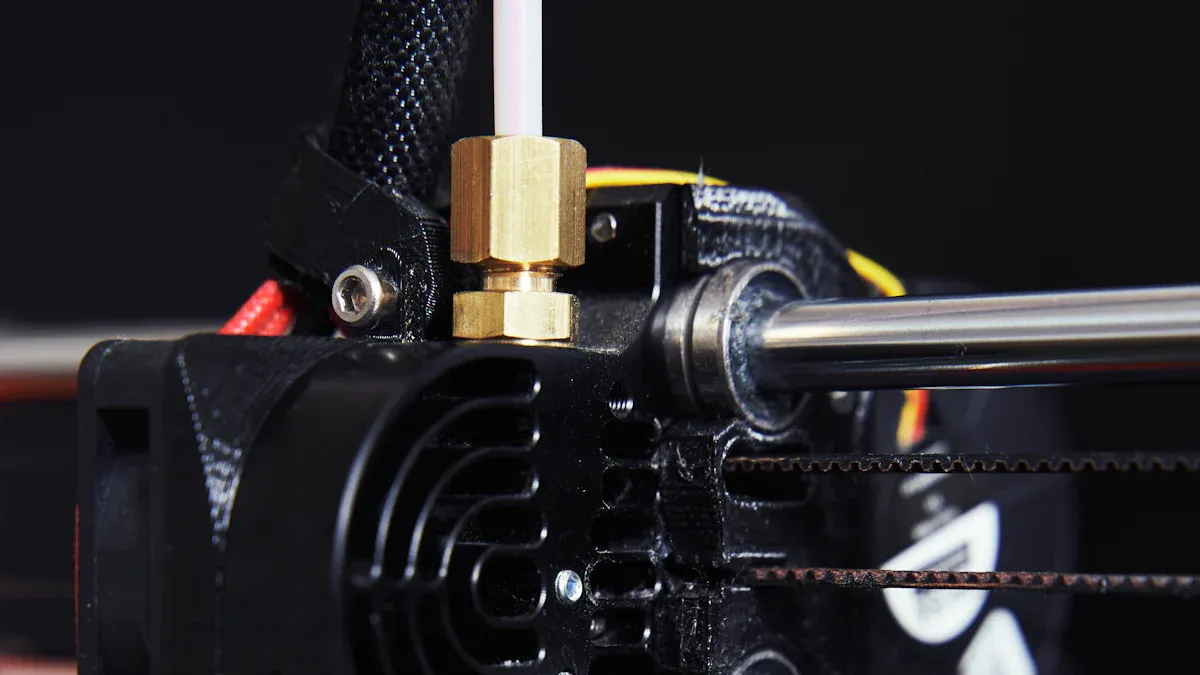

Onjiniyela bancike kubhareli yesikulufu enwetshiwe engakwesokudla kanye nesikulufu ukuze bathole imiphumela ye-extrusion engaguquki nekhwalithi ephezulu.

Izingxenye ze-Conical Twin Screw Barrel kanye Nomklamo

Isakhiwo kanye neJiyomethri Eqoshiwe

Isakhiwo se-aI-Conical Twin Screw Barreligqamile ngenxa yejiyomethri yayo ehlukile. Lo mklamo ufaka ukwehla kancane kancane kobubanzi besikulufa ukusuka endaweni yokuphakelayo ukuya endaweni yokukhipha. I-tapering idala ukusabalalisa kwamandla okugunda okuguquguqukayo nokufana okufanayo. Lokhu kusiza ukuthuthukisa ukuxubana nokuqinisekisa ukuthi izinto zihlangana ngokulinganayo. I-geometry iphinde inciphise ivolumu ngaphakathi komgqomo njengoba izinto ziqhubekela phambili. Lolu shintsho luthuthukisa ukuthunyelwa kwezinto futhi lunciphise ubungozi bokuvinjwa.

Idizayini ene-tapered yehlisa ukumelana nokusebenzisa amandla, okwandisa ukusebenza kahle kwamandla. Iphinde ikhuthaze ngisho nokusabalalisa ukushisa. Lokhu kuvimbela izindawo ezishisayo futhi kuthuthukisa ukuphathwa kokushisa. I-geometry idala amaphethini okugeleza ayinkimbinkimbi athuthukisa ukusebenza kahle kokuxuba. Ngenxa yalokho, inqubo ayidingi ukugunda ngokweqile noma okokufaka kwamandla engeziwe. Ukuncishiswa okulawulwayo kobubanzi kuvumela ukulawula okunembile kokuthi izinto ezisetshenziswayo zihlala isikhathi esingakanani emgqonyeni. Lokhu kuholela ekucutshungulweni okusebenzayo kanye nezakhiwo zempahla ezingcono.

Ezinye izici ezibalulekile zedizayini zifaka:

- Ukukhushulwa kwesilinganiso sobude nobubanzi, enweba indlela yokucubungula futhi ivumele isikhathi esengeziwe sokuguqulwa kwezinto ezibonakalayo.

- Izindawo zokushisa eziningi, ngayinye ilawulwa ngokuzimela, ukuze ilawule ukushisa okunembile.

- Ukucindezelwa kwe-shear okuncishisiwe, okuvikela izinto ezizwela ukushisa futhi kuthuthukisa ukuqagela kwenqubo.

- Ukuhlukahluka ekucubunguleni izinto ezihlukahlukene, ngenxa yomklamo oguquguqukayo we-tapered.

Izinto Ezibalulekile Ezisetshenzisiwe

Abakhiqizi bakhetha izinto zokwakhaIzingxenye ze-Conical Twin Screw Barrelngokusekelwe ukuqina nokusebenza. Umgqomo nezikulufu kuvame ukusebenzisa izinsimbi ze-alloy eziqinile. Lezi zinto zimelana nokugqoka nokugqwala, okubalulekile ekusebenzeni isikhathi eside. Eminye imiphongolo ithola ukwelashwa okukhethekile kwendawo noma ukumbozwa. Lezi zindlela zokwelapha ziphinde zikhulise ukumelana nemihuzuko nokuhlaselwa ngamakhemikhali.

Izinto ezijwayelekile zifaka:

- Insimbi ye-nitrided, enikeza ubulukhuni obuhle kakhulu bobuso.

- Ama-alloys e-Bimetallic, ahlinzeka ngokuvikeleka okwengeziwe ezindaweni ezigqoke kakhulu.

- Insimbi engagqwali, emelana nokugqwala lapho icutshungulwa izinhlanganisela ezinolaka noma ezisebenzayo.

Ukukhethwa kwezinto kuncike ohlotsheni lwe-polymer noma inhlanganisela ecutshungulwayo. Isibonelo, imiphongolo esetshenziselwa ukukhishwa kwe-PVC ivamise ukudinga izinto ezikwazi ukumelana nemvelo yokugqwala yamakhompiyutha asekelwe ku-chlorine. Lokhu kukhetha ngokucophelela kuqinisekisa ukuthi i-Conical Twin Screw Barrel igcina ukusebenza okuphezulu kanye nempilo ende yesevisi.

Izinhlobo Zezikulufu Nezindima Zazo

Isikulufu siyingxenye ebalulekile ye-Conical Twin Screw Barrel. Izinto eziyisikulufa ezihlukene zenza imisebenzi ethile phakathi nenqubo yokukhipha. Onjiniyela baklama lezi zakhi ukuze kuthuthukiswe ukuxutshwa, ukuncibilika, nokudlulisa.

| Uhlobo lwe-Screw Element | Ipharamitha Yobuningi Ikaliwe | Iqhaza Ekuhlanganiseni / Emthelela Kunqubo |

|---|---|---|

| Izinto Zokuhola Ezizodwa | Ukusabalalisa Isikhathi Sokuhlala | Ithonya izici zokuhlanganisa nokugeleza kwe-axial |

| Ukuhlanganisa ama-Paddles | I-Viscous Dissipation, i-RTD | Thuthukisa ukuhlanganisa okuhlakazekayo nokusabalalisa ngokwandisa amandla okugunda kanye nokunwebeka |

| Ama-Pitch Elements Ahlehlisiwe | Ukusabalala Kwejika, Ukuma | Lungisa amaphethini okugeleza ukuze unciphise ukuma futhi uthuthukise ukuxutshwa kokusabalalisa |

Ama-elementi okuhola awodwa alawula ukuthi izinto ezisetshenziswayo zihlala isikhathi esingakanani emgqonyeni futhi zisize ukuziyisa phambili. Ukuxuba ama-paddles kwandisa amandla okugunda kanye nokwelula, ahlukana futhi ahlanganise izinto ngokugcwele. Izakhi zephimbo ezihlehlisiwe zishintsha isiqondiso sokugeleza. Lokhu kunciphisa izindawo lapho okubalulekile kungase kumile futhi kuthuthukisa ukuxubana okuphelele.

Onjiniyela bangalungisa ukumiswa kwalezi zici zesikulufu ukuze zifane nezidingo zezinto ezihlukile nezinqubo. Lokhu kuvumelana nezimo kwenza i-Conical Twin Screw Barrel ilungele uhla olubanzi lwezinhlelo zokusebenza ze-extrusion.

Indlela I-Conical Twin Screw Barrel esebenza ngayo ku-Plastic Extrusion

Izimiso Zokusebenza

I-Conical Twin Screw Barrel isebenza ngokugxila ekululameni nokusebenza kahle. Onjiniyela baklama lawa masistimu ukuze asingathe izinhlobonhlobo zezidingo ze-plastic extrusion. I-conical geometry ikhiqiza i-torque ephezulu ngenkathi igcina ipulasitiki ethambile. Lesi sici sibalulekile ekucubunguleni izinto ezizwela ukushisa nokugunda. Izikulufu zinendawo ephezulu kanye nephrofayili ye-shear ephansi, evumela ukudluliswa kokushisa okusebenzayo ngesikhathi sokukhipha.

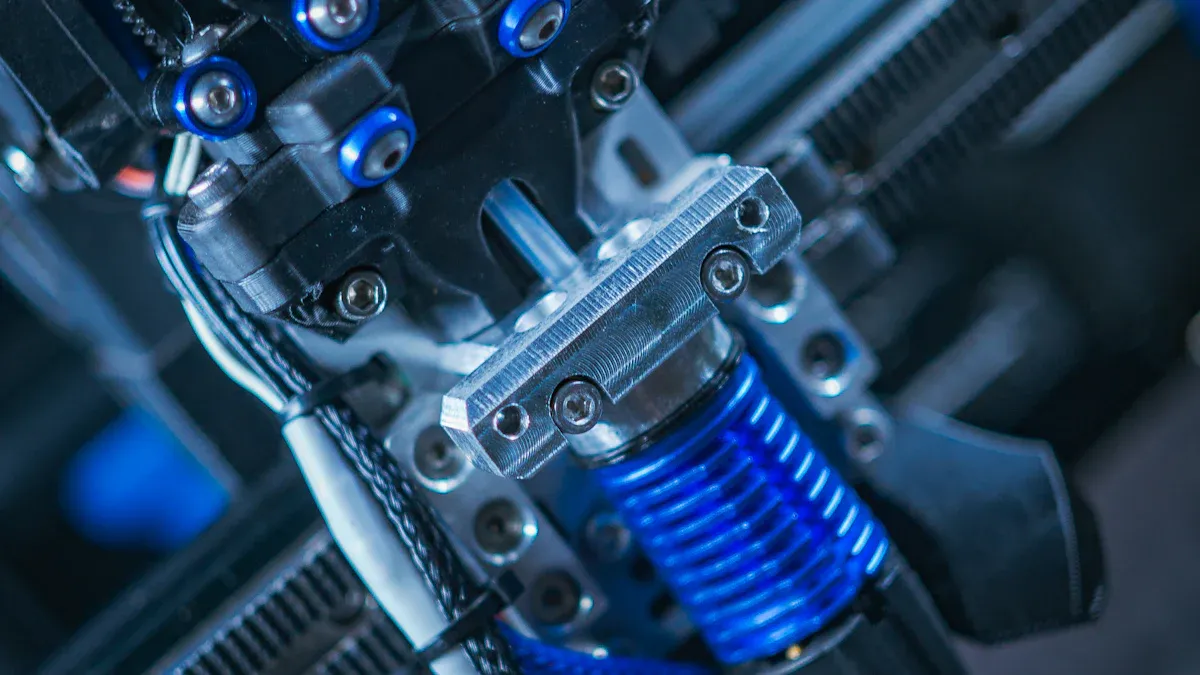

Abakhi bavamise ukusebenzisa okokuvikela okuphathelene, okufana ne-nitride noma i-tungsten, kuzikulufu nemiphongolo. Lezi zembatho zandisa ukumelana nokugqoka futhi zithuthukise ukudluliswa kokushisa. Idizayini ye-modular nokulungiselelwa kwesikulufu esenziwa ngendlela oyifisayo kusiza ukuthuthukisa inqubo yokukhipha izinhlelo zokusebenza ezahlukene. Insimbi yekhwalithi ephezulu ye-DIN yakha into eyisisekelo, enezinketho ze-chrome plating noma i-carbide encapsulation yokusetshenziswa okufunayo.

Ama-opharetha aqapha amapharamitha ambalwa ngesikhathi sokukhipha:

- Izinga lokushisa

- Ncibilikisa ingcindezi

- Torque

- Isivinini sesikulufa

- Izinga lokuphakelayo

Lezi zilinganiso zibonisa indlela okokusebenza okuziphatha ngayo ngaphakathi komgqomo futhi ziqinisekisa ukusebenza kahle kwesistimu.

Ukuncibilika, Ukuxuba, kanye Nenqubo Yokudlulisa

Ukuncibilika, ukuxutshwa, kanye nezindlela zokudlulisa zincike ekulawuleni okunembayo kwamapharamitha wenqubo nokuklanywa kwesikulufu. Ithebula elilandelayo libonisa ukuthi ipharamitha ngayinye noma isici somklamo siqinisekisa kanjani lezi zindlela:

| Ipharamitha Yenqubo / Isici Somklamo | Iqhaza Kuhlelo Lokuqinisekisa |

|---|---|

| Isivinini seScrew (rpm) | Ilawula izinga lokugunda, ithonya ukuncibilika kanye namandla okuxuba |

| Izinga lokuphakelayo | Kuthinta isikhathi sokuhlala nokusebenza kahle kokuncibilika |

| Torque | Ibonisa umthwalo wemishini namandla okufaka ukuze kuncibilike futhi kudluliselwe |

| Ingcindezi | Ibonisa ukumelana nokugeleza kwezinto kanye nokusebenza kahle kokudlulisa |

| Izinga lokushisa | Iqapha isimo sokuncibilika kanye nezimo ezishisayo |

| Ukusabalalisa Isikhathi Sokuhlala (RTD) | Iqinisekisa ukuxuba okufanayo kanye nesikhathi sokuchayeka ekugundani nasekushiseni |

| I-Screw Geometry | Inquma isivinini sokudlulisa, ukuqina kwe-shear, nohlobo lokuxuba |

| Ukuxuba Izinto | Yenza kube lula ukuxubana okusabalalisa nokuhlakazekayo, okuthinta i-melt homogeneity |

Ama-opharetha alungisa le mingcele ukuze bathole ukuncibilika okufanayo, ukuxutshwa okuphelele, kanye nokuthuthwa kwezinto ezisebenzayo. Idizayini ye-Conical Twin Screw Barrel iqinisekisa ukuthi isigaba ngasinye senqubo sisekela imiphumela yekhwalithi ephezulu ye-extrusion.

I-Conical Twin Screw Barrel vs. Ezinye Izinhlobo

I-Conical vs. Parallel Twin Screw Barrels

Imiphongolo yesikulufu e-Conical ne-parallel twin isebenza izindima ezifanayo ku-plastic extrusion, kodwa imiklamo yabo idala izinzuzo ezihlukene zokucubungula. Idizayini eyikhonikhi isebenzisa izikulufu ezicijile, ezidala igebe elincane njengoba impahla iya phambili. Lesi sici sikhulisa ukucindezelwa kokubalulekile futhi sithuthukisa ukukhishwa kwegesi. Iphinde ivumele ukudluliswa kwetorque ephezulu, iyenze ifaneleke ezintweni ezinokuminyana kwenqwaba noma lezo ezibamba igesi. Imiphongolo yesikulufu ehambisanayo, ngakolunye uhlangothi, sebenzisa izikulufu ezinobubanzi obungaguquki. Lezi zinhlelo zihamba phambili ekuxubeni nasekuhlanganiseni, ikakhulukazi uma izikulufu zizungeza ohlangothini olufanayo. Imiklamo ehambisanayo ikhuthaza ukuzihlanza kanye nokuhlakazeka okufanayo. Amamodeli ezibalo abonisa ukuthi ama-conical twin screw barrel athuthukisa umthamo wokuthatha kanye nokukhiqizwa kwengcindezi, okuholela ekusebenzeni kahle kwe-extrusion uma kuqhathaniswa nemiklamo efanayo.

- Imiphongolo eyi-Conical: Ingcono yokuminyanisa, yokususa umoya, ne-torque.

- Imiphongolo ehambisanayo: Ingcono ukuxutshwa, ukuhlanganisa, nokuzihlanza.

Izinzuzo Eziyingqayizivele Zomklamo Oyi-Conical

I-design conical inikeza izinzuzo eziningana eziyingqayizivele. Ithuthukisa okukhiphayo kanye nokukhiqiza, ikakhulukazi ekukhiqizeni amapayipi e-PVC. Ukwehliswa kancane kancane kwevolumu yesikulufu sesiteshi kwandisa ingcindezi futhi kuthuthukisa ukuhlanganisa. Lo mklamo uphinde usekele ukugunda okuthambile, okuvikela izinto ezingezwani nokushisa. Ama-opharetha angakwazi ukulungisa isivinini nesikulufu nobubanzi ukuze bakhulise amanani okukhiphayo kanye nekhwalithi yokuncibilika. I-conical twin screw barrel ithuthukisa ukuxubana, okuholela kumbala ofanayo kanye nezakhiwo ezingcono zemishini emikhiqizweni eqediwe. Amasistimu okulawula athuthukile athuthukisa ukusebenza kahle kwenqubo nokuvumelana komkhiqizo.

Idizayini eyikholi futhi isiza ukunciphisa ukusetshenziswa kwamandla nokumosha, isekela ukukhiqizwa okungabizi kakhulu nokusimeme.

Izicelo Ezijwayelekile

I-Conical Twin Screw Barrel ithola ukusetshenziswa ezimbonini eziningi. IyacubungulaAmapayipi e-PVC, amaphrofayili, namashidingekhono eliphezulu. Abakhiqizi bayisebenzisela amapulasitiki okunzima ukuwasebenzisa kabusha kanye nama-polymer ebanga lezokwelapha. Idizayini isekela amazinga aphezulu okukhiphayo, ngeamaphrofayili afinyelela ku-550 lb/hr namapayipi afika ku-1000 lb/hr. Iphinde ithuthukise ikhwalithi yomkhiqizo ngokunciphisa izimbobo kanye nokuqinisekisa umswakama ofanayo. Izimboni ezifana nemithi, amapulasitiki, nezinhlanganisela ziyazuza ekwakhiweni kwazo okumodulayo nokuvumelana nezimo.

| Indawo Yesicelo | Inzuzo Ihlinzekiwe |

|---|---|

| Ukwenziwa Kwepayipi Le-PVC | Ukukhipha okuphezulu, ukuncibilika okufanayo, ikhwalithi ezinzile |

| Iphrofayili Extrusion | Ukuxuba okuthuthukisiwe, ubukhulu obunembile |

| I-Medical Polymers | Ukucubungula okumnene, izakhiwo ezingaguquki |

| Ipulasitiki Esenziwe Kabusha | Ukuphatha izinto ezihlukahlukene, ukonga izindleko |

Ukukhetha i-Conical Twin Screw Barrel

Ukuhambisana Kwezinto ezibonakalayo

Ukukhetha i-Conical Twin Screw Barrel efanele kuqala ngokuqonda ukuhambisana kwezinto. Onjiniyela kufanele bafanise idizayini yomgqomo nesikulufu nezici ezithile zezinto ezicutshungulwayo. Ngokwesibonelo,Imikhiqizo ye-PVCzidinga ukucushwa kwesikulufu okuhlukile kune-polyolefin noma amapulasitiki obunjiniyela. Izifundo zezinombolo zisiza onjiniyela balingise ukuthi imiklamo ehlukene yezikulufu nokusethwa kwemiphongolo kuthinta kanjani ukugeleza kwezinto, ukuncibilika, nokuxutshwa. Lezi zifaniso zibonisa ukuthi ijiyomethri eyisikulufu namapharamitha okucubungula—njengezinga lokushisa, isivinini sesikulufu, nezinga lokuphakelayo—kuthinta kanjani ukuziphatha kokubalulekile ngaphakathi kombhobho.

Lapho becubungula izinto ezibucayi, onjiniyela kufanele balawule ukugunda nokushisa ukuze bagweme ukuwohloka. Balungisa ukubekwa kwesici sesikulufa kanye nobude bomphongolo ukuze baqinisekise ukuxutshwa nokuncibilika. Izinto ezigugulekayo noma ezibolayo zidinga amalayini emiphongolo akhethekile noma ama-screw coatings ukugwema ukulimala. Ngokukhetha ngokucophelela inhlanganisela efanele yeisikulufu nomgqomo, opharetha bagcina ubuqotho bezinto ezibonakalayo futhi bathole ikhwalithi yomkhiqizo engaguquki.

Ithiphu: Njalo buyekeza indawo encibilikayo, i-viscosity, kanye nokusebenza kabusha kwekhemikhali ngaphambi kokukhetha ukulungiselelwa kwesikulufu.

Gqoka Ukumelana Nokuqina

Ukuqina kudlala indima ebalulekile ekusebenzeni nasekuphileni kwe-twin screw barrel. Abakhiqizi basebenzisa ama-alloy steels anamandla aphezulu, izindawo ezine-nitrided, nama-bimetallic linings ukumelana nokuguga nokugqwala. Lezi zinto zivikela umgqomo nezikulufu ekuhutsheni okubangelwa izigcwalisi, imicu yengilazi, noma izithasiselo zamaminerali. Ngezinhlelo zokusebenza ezilimaza kakhulu noma ezibolayo, onjiniyela bangacacisa ezinye izindlela zokwelapha ezingaphezulu noma ama-coatings.

Ithebula elingezansi lifingqa ukukhetha kwezinto ezivamile kanye nezinzuzo zazo:

| Uhlobo Lwezinto | Inzuzo Ihlinzekiwe | Uhlelo lokusebenza olujwayelekile |

|---|---|---|

| Insimbi ye-Nitrided | Ukuqina kwendawo ephezulu | Ukucubungula kwe-polymer okujwayelekile |

| I-Bimetallic Alloy | Ukumelana okuphezulu kwe-abrasion | Amapulasitiki agcwele noma aqinisiwe |

| Insimbi engagqwali | Ukumelana nokugqwala | Izinhlanganisela ezisebenzayo noma ezinolaka |

Ukuhlolwa okuvamile nokushintshwa ngesikhathi kwezingxenye ezigugile kusiza ukugcina ikhwalithi ye-extrusion engaguquki. Ukukhetha izinto ezifanele zomgqomo nezikulufu kunciphisa isikhathi sokuphumula futhi kwandisa impilo yesisetshenziswa.

Ukucatshangelwa Kokugcinwa Nokufakwa

Ukugcinwa nokufakwa ngendlela efanele kuqinisekisa ukusebenza okuthembekile kanye nempilo ende yesevisi yomphongolo we-screw twin conical. Ama-extruder esimanje, njenge-Gemini® Conical Twin Screw Extruders, anezikulufu eziphansi ze-rpm ezinamasistimu okupholisa amanzi angaphakathi, amabhokisi aqinile, nama-heaters asebenza kahle emiphongolweni epholile. Lezi zici zidinga ukuhlela ngokucophelela phakathi nokufakwa. Abasebenzisi kufanele bahlinzeke ngengqalasizinda esebenzayo yokupholisa, ukusekela okuqinile kwebhokisi lamagiya, kanye nezindlela ezanele zokuphakela ukuze bathole ukusebenza kahle.

Izinhlelo zokunakekela, ezifana nalezo ezinikezwa i-Milacron, zifaka phakathi ukugcinwa kwesitoko nokwakha kabusha imiphongolo nezikulufu. Lezi zinsizakalo zivumela opharetha ukuthi balule isikhathi semishini yabo futhi bagcine ubuqotho bokufaka. Ukwakhiwa kabusha kwe-Gearbox nokuthuthukiswa nakho kudlala indima ebalulekile ekugcineni i-extruder izinzile futhi ithembekile.

Qaphela: Hlela ukuhlolwa okuvamile futhi ugcine amarekhodi anemininingwane yokulungisa. Ukufinyelela okusheshayo kumasevisi okwakha kabusha nezingxenye ezisele kusiza ukunciphisa isikhathi sokuphumula futhi kuqinisekise ukukhiqizwa okuqhubekayo.

Umthelela we-Conical Twin Screw Barrel ekusebenzeni kwe-Extrusion

Ukusebenza kahle kanye Nekhwalithi Yokukhiphayo

I-Conical Twin Screw Barrel ithuthukisa ukusebenza kahle kwe-extrusion ngokuthuthukisa ukugeleza kwezinto ezibonakalayo nokuxuba. I-intermeshing screw design kanye nesimo se-conical kwandisa indawo engaphezulu engxenyeni ye-plasticizing. Lo mklamo usiza ukusabalalisa ukushisa ngokulinganayo futhi wehlise ukumosheka kwamandla. Ama-opharetha aqaphela ukuncibilika okufanayo okufanayo nokulawula izinga lokushisa okungcono. Lezi zici zehlisa ubungozi bokuwohloka kwezinto futhi zithuthukise ukuhambisana komkhiqizo.

Imigqa yokukhiqiza esebenzisa lolu hlobo lomgqomo ivamise ukubona isivinini esisheshayo sokukhipha kanye nokuphumayo kwekhwalithi ephezulu.Ukusetshenziswa kwamandla kungehla kufika ku-30%uma kuqhathaniswa nemiphongolo yendabuko. Ukuqina okuthuthukisiwe kwezikulufu nemiphongolo nakho kusho ukuphumula okuncane kokulungiswa. Iithebula elingezansi ligqamisa amamethrikhi okusebenza angukhiye:

| Imethrikhi / Isici | Inani / Incazelo |

|---|---|

| Ukukhiqiza Ngempumelelo | Kuthuthukiswe kakhulu |

| Ukusetshenziswa kwamandla | Ukwehliswa okukhulu |

| Izilinganiso Zezinsimbi | Ukwehliswa okukhulu |

| Ukuncishiswa Kwezikulufu | Kufikela ku-60% ukuncishiswa |

| Ukwenyuka Kokusebenza | Kufika ku-25% ukwenyuka |

| I-Waste Rate | ~1.5% |

| Isikhathi sokuqalisa sobukhulu obusha | 1 kuya ku-2 amahora |

Le miphumela ibonisa ukuthi i-Conical Twin Screw Barrel isekela ukukhiqizwa okuzinzile, inciphisa ukumosha, futhi inyusa ikhwalithi yokuphumayo.

Izindleko-Ngempumelelo

Abakhiqizi bayazuza ekusebenziseni izindleko zalo mklamo womgqomo. Ukusetshenziswa kwamandla aphansi kunciphisa ngqo izindleko zokusebenza. Izinto eziqinile kanye nama-coatings athuthukisiwe anweba impilo yakho kokubili umgqomo nezikulufu. Lokhu kuqina kusho ukushintshwa okumbalwa kanye nokunakekelwa okungajwayelekile.

Izilinganiso ezincishisiwe ze-scrap kanye nezikhathi zokuqalisa ngokushesha nazo zisiza ukonga imali. Abasebenzisi bachitha isikhathi esincane behlanza futhi belungisa izinto zokusebenza. Ithebula elingenhla libonisa lokhoamazinga kadoti ehla aze afike ku-1.5%, futhi izikhathi zokuqalisa zobukhulu bemikhiqizo emisha ziba mfushane zibe amahora angu-1 ukuya kwangu-2. Lokhu kuthuthukiswa kuvumela izinkampani ukuthi zikhiqize okuningi ngezinsiza ezimbalwa.

Ithiphu: Ukutshala imali ku-Conical Twin Screw Barrel kungaholela ekongeni kwesikhathi eside kanye nokukhiqiza okuthembekile.

I-Conical Twin Screw Barrel iletha ukulawula okunembayo nokusebenza kahle okuphezulu ku-extrusion yepulasitiki. Ucwaningo lubonisa amapharamitha we-extrusion athuthukisiwe aholela emiphumeleni engaguquki kanye nesivuno esithuthukisiwe. Abasebenzisi kufanele bafanise ukwakheka komgqomo nezidingo zezinto ezibonakalayo futhi baqaphe okuguquguqukayo kwenqubo. Ukukhetha okunolwazi kuqinisekisa ukusebenza okuthembekile kanye nekhwalithi yomkhiqizo ephezulu.

FAQ

Yiziphi izimboni ezisebenzisa ama-conical twin screw barrel?

Abakhiqizi bamapulasitiki, ezokwakha, nezimboni zemishini yezokwelapha basebenzisaama-conical twin screw imiphongoloukukhiqiza amapayipi, amaphrofayili, kanye nemikhiqizo ye-polymer ekhethekile.

Ingabe opharetha kufanele bahlole kangaki umphongolo wesikulufu esiwukhonkolo?

Abasebenzi kufanelehlola umgqomonjalo. Ochwepheshe abaningi batusa ukuhlolwa kwanyanga zonke ukuze kuqinisekiswe ukusebenza kahle nokuvimbela isikhathi sokuphumula esingalindelekile.

Ingabe i-conical twin screw barrel process materials ngaphandle kwe-PVC?

Yebo. Imiphongolo yesikulufu ephindwe kabili ibamba izinhlobonhlobo zamapholima, okuhlanganisa i-polyolefin namapulasitiki obunjiniyela, ngokulungisa idizayini yesikulufu namapharamitha okucubungula.

Isikhathi sokuthumela: Jul-02-2025