Amandla e-Shear adlala indima ebalulekile ekusebenzeni kwe-plastic twin screw extruder. Kubhekiselwa kumandla adala ukuthi izendlalelo zezinto zishibilike zibhekane, kube nomthelela omkhulu ezintweni ezibonakalayo. Isibonelo, amandla aphezulu okugunda athuthukisa ukuxubana nokusabalalisa ukushisa. Phakathi kuI-Twin Plastic Screw Barrel, umklamo wendawo encibilikayo uqinisekisa ukugeleza kwezinto ezisebenzayo kuyilapho unciphisa izinga lokushisa, njengoba ukucindezela kwamabha angu-40 kungakhuphula izinga lokushisa ngo-20°C. Ngaphezu kwalokho, aI-Conical Twin Screw Extruder Screw Barrelithuthukisa futhi lezi zinqubo ngokulinganisa amandla e-shear kanye ne-throughput, kuyilapho iI-Twin Screw Barrelukuklama kunomthelela ekusebenzeni kahle okuphelele kunqubo ye-extrusion.

Okuyisisekelo kwePlastiki Twin Screw Extruder

Izingxenye Eziyinhloko ze-Extruder

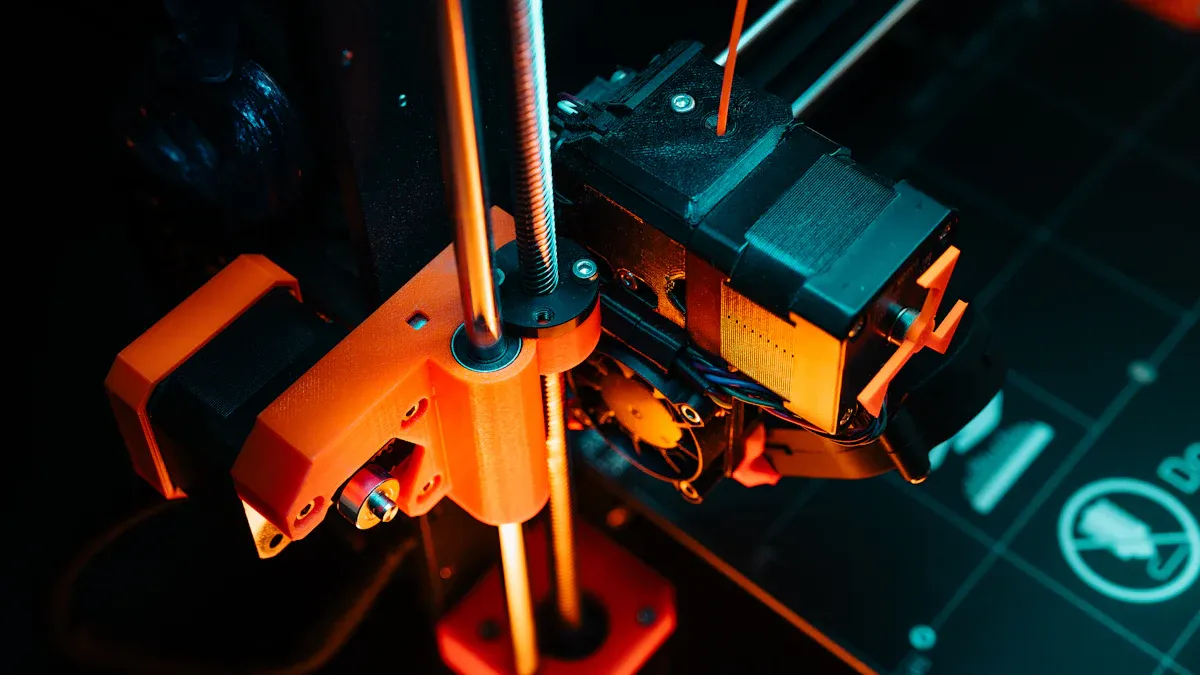

A plastic twin screw extruderiqukethe izingxenye ezimbalwa ezibalulekile ezisebenza ndawonye ukuze zicubungule izinto ngendlela efanele. Lokhu kubandakanya:

- I-Hopper: Indawo yokungena lapho izinto zokusetshenziswa zifakwa khona ohlelweni.

- Umgqomo: Igumbi elikhulu lapho kuncibilika khona futhi kuxutshwe izinto zokwakha.

- Isikulufa Conveyor: Unomthwalo wemfanelo wokuthutha izinto nge-extruder.

- Isistimu Yokushisa: Ihlinzeka ngokushisa okudingekayo kokuncibilikisa izinhlanganisela zepulasitiki.

- Ukulawula izinga lokushisa: Iqinisekisa izimo zokucubungula ezingaguquki.

- I-Extrusion Head: Ilolonga impahla ibe yifomu oyifunayo njengoba iphuma ku-extruder.

Ingxenye ngayinye idlala indima ebalulekile ekuqinisekiseni ukuthi i-extruder isebenza kahle futhi iletha okukhiphayo kwekhwalithi ephezulu. Isibonelo, isivinini esiguquguqukayo sesikulufu sivumela ukulawula okunembile phezu kwenqubo yokukhipha, kuyilapho ukufa okungashintshwa kunika amandla ukukhiqizwa komumo nosayizi abahlukahlukene.

Iqhaza Lezikulufu kanye Nemigqomo ku-Shear Force Generation

Izikulufu kanye nomgqomo kumaphakathi ekukhiqizeni amandla okugunda kusikulufa se-plastic twin screw extruder. Izikulufu zizungeza ngaphakathi komgqomo, zenze ukungqubuzana nokucindezela okuncibilika futhi kuxube okokusebenza. Izinto ezifana nesivinini sesikulufu, ububanzi bokufa, nokuziphatha okubalulekile kunomthelela kakhulu kumandla wokugunda. Ngokwesibonelo:

| Ipharamitha | Ithonya ku-Shear Force Generation |

|---|---|

| Isivinini seScrew | Izivinini eziphakeme zikhuphula izinga lokuphuma kanye namandla ahlakaziwe, kukhuphula amandla okugunda. |

| I-Die Diameter | Amadayimitha amakhulu anciphisa ingcindezi namandla, athinte amandla okugunda. |

| Ukuziphatha Okubalulekile | Izinto ezinciphisa i-shear zibonisa ingcindezi ephansi namandla uma kuqhathaniswa noketshezi lwe-Newtonian. |

Lokhu kusebenzisana kuqinisekisa ukucubungula okusebenzayo kwezinto kanye nokuxuba okufanayo.

I-Material Flow Dynamics ku-Extruder

Amandla okugeleza kwezinto ku-plastic twin screw extruder anquma ikhwalithi yokuxuba nomkhiqizo wokugcina. Izindlela ezithuthukisiwe zokubala, ezifana ne-CFD, zithuthukise ukuqondwa kwala mandla. Amasu afana nevolumu yoketshezi (i-VOF) nezindlela zokusetha izinga zilandelela ukuxhumana koketshezi ngesikhathi sokuxutshwa, okuqinisekisa ukulawula okunembile phezu kwenqubo. Ama-twin screw extruder asetshenziswa kakhulu ezimbonini ezifana nezamakhemisi ngenxa yamakhono azo okuxuba aphakeme. Ngaphansi kwezimo ezijwayelekile (30 kg/hr, 200 rpm), ingcindezi egunjini elilodwa elimise okwe-C ifinyelela cishe ku-2.2 MPa, nokwehla kokucindezela okungu-0.3 MPa endaweni yokuhlangana kanye no-0.5 MPa kusici sesikulufu esibuyela emuva. Lawa mamethrikhi agqamisa ukusebenza kahle kwe-extruder ekuphatheni izinto ezihlukahlukene.

I-Shear Force Mechanism ku-Twin Screw Extrusion

Isizukulwane Samandla E-Shear Enqubweni Yokukhipha

Amandla e-shear kunqubo yokukhipha isikulufu esingamawele avela ekusebenzelaneni phakathi kwezikulufu ezizungezayo kanye nomgqomo omile. Njengoba izikulufi zizungeza, zenza ukungqubuzana nokucindezela, okubangela ukuthi impahla igxumeke futhi igeleze. Lokhu kuguqulwa kudala amandla okugunda adlala indima ebalulekile ekuncibilikiseni, ekuxubeni nasekuhlanganiseni izinto ngendlela efanayo. Idizayini yokuhlanganisa izikulufu iqinisekisa ukuthi okokusebenza kuthola ukugunda okufanayo kuyo yonke inqubo.

Ukuhlaziywa kwezinombolo kusetshenziswa indlela ye-volume-of-fluid (VOF) kwembule izindlela ze-hydrodynamic ezihilelekile kule nqubo. Igqamisa ukuthi amandla okugunda, izilinganiso ze-viscosity, kanye ne-turbulence kuthonya kanjani i-microstructure yama-alloys angabonakali ngesikhathi sokuxuba. Lokhu okutholakele kugcizelela ukubaluleka kwamandla e-shear ekunqumeni ukuziphatha kwe-rheological kanye nokusebenza okuphelele kwenqubo ye-extrusion.

Ucwaningo lokuhlola luqhubeka nokusekela le ndlela. Isibonelo, ucwaningo lwe-polypropylene-clay nanocomposites lubonise ukuthi ama-extruder angamawele angama-screw athola ukuhlakazeka okuphezulu uma kuqhathaniswa nama-screw extruder esisodwa. Lokhu kubangelwa amandla aphezulu okugunda akhiqizwe ezinhlelweni zama-screw angamawele, athuthukisa ukucwecwa kwezinto futhi athuthukise izakhiwo zazo zemishini nezokushisa.

Izinto Ezithinta Amandla E-Shear

Kunezici ezimbalwa ezithonya ukukhiqizwa nobukhulu bamandla okugunda kusikulufa samawele epulasitiki. Lokhu kufaka phakathi isivinini sesikulufu, i-screw geometry, kanye ne-viscosity yezinto ezibonakalayo.

- Isivinini seScrew: Ukwenyusa isivinini sesikulufu kuphakamisa izinga lokugunda, okuholela kumandla aphezulu wokugunda. Kodwa-ke, isivinini esikhulu singabangela ukuwohloka kwezinto noma ukushisa ngokweqile.

- I-Screw Geometry: Idizayini yezikulufu, okuhlanganisa ukuphakama kwazo, ukujula kwendiza, ne-engeli ehlanganayo, kuthinta ngokuqondile isenzo sokugunda. Isibonelo, izikulufu ezinezindiza ezijulile zenza amandla okugunda aphansi, kuyilapho ama-engeli ahlanganayo aqinile akhulisa ukugunda.

- I-Viscosity yezinto ezibonakalayo: Izinto ze-viscosity eziphezulu zidinga amandla amakhulu okugunda ukuze kuzuzwe ukuxuba nokuncibilika okufanele. Ngokuphambene, izinto ze-viscosity ephansi zingageleza kalula, zinciphise ukusebenza kwesenzo sokugunda.

Ucwaningo lwezibalo luhlaziye lezi zici ngokuningiliziwe. Isibonelo, ucwaningo luveze ukuthi uhlobo oluqoqiwe lukhuphuka ngokuhambisana nesivinini sesikulufu kodwa lwehla ngezinga lokuphakelayo. Izimo ezikahle zokucubungula, njengezinga lokuphakelayo elingu-3.6 kg/h ngesivinini esikulukulu esingu-95 rpm, sikhuphula izinga lokushisa ngenkathi sinciphisa ukuphuka kwefayibha. Lokhu okutholakele kugqamisa isidingo sokulinganisa lezi zici ukuze kuzuzwe i-extrusion ephumelelayo.

Izindlela zokulawula i-Shear Force

Ukulawula amandla e-shear kubalulekile ekuthuthukiseni inqubo ye-extrusion kanye nokuqinisekisa ikhwalithi yomkhiqizo engaguquki. Kungasetshenziswa izindlela ezimbalwa ukulawula amandla e-shear ku-twin screw extruder:

- Ukulungisa Isivinini Se-Screw: Ama-opharetha angakhuphula noma anciphise isivinini sesikulufu ukuze alungise izinga lokugunda futhi azuze izici ezibonakalayo ezifiselekayo.

- Ukwenza ngokwezifiso i-Screw Design: Ukuhlanganisa ijiyomethri yesikulufu, njengokushintsha ukuphakama noma ukujula kwendiza, kuvumela ukulawula okunembile kwesenzo sokugunda.

- Ukusebenzisa Amamodeli Wokunciphisa I-Shear: Lawa mamodeli asiza ukubikezela ukuziphatha okubalulekile ngaphansi kwezimo ezihlukene zokugunda, okuvumela ukulawula inqubo engcono. Kodwa-ke, ukuthembela kuphela kulawa mamodeli kungaholela ekubukelweni phansi kwemingcele ebalulekile njengokucindezela kanye ne-viscosity.

- Ukusebenzisa Izinhlelo Zokuqapha Ezithuthukile: Ukuqapha kwesikhathi sangempela kwamapharamitha afana nezinga lokushisa, ingcindezi, netorque kunikeza imininingwane ebalulekile enqubweni ye-extrusion. Le datha ingasetshenziswa ukwenza izinguquko kanye nokugcina amazinga aphezulu wamandla okugunda.

Ucwaningo lubonise ukuthi indima yesikulufu ekudluliseni ukushisa ibalulekile ekulawuleni amandla okugunda. Isekhethi yokuzungeza kabusha iyakha ngaphakathi kwe-extruder, esiza ukusabalalisa ukushisa ngokulinganayo futhi ivimbele ukushisa okweqile kwendawo. Lokhu kuqinisekisa ukuthi i-polymer incibilika ngokufanayo, ithuthukisa ukusebenza kahle okuphelele kwenqubo ye-extrusion.

Umthelela we-Shear Force Ezimpahleni Ezibalulekile

Imithelela ekuxubeni kanye ne-Homogeneity

Amandla e-Shear adlala indima ebalulekile ekuzuzeni ukuxubana okufanayo kanye nokufana kwezinto ezicutshungulwa yi-plastic twin screw extruder. Ukusebenzisana phakathi kwezikulufu nomgqomo kudala ukungqubuzana, okusiza ukuhlangana kwama-polymers nezithasiselo. Le nqubo iqinisekisa ukuthi umkhiqizo wokugcina ubonisa izici ezingaguquki kuso sonke isakhiwo sawo.

Izifundo zokuqina zigqamisa izici ezimbalwa zomthelela we-shear force:

| Isici se-Shear Force Impact | Incazelo |

|---|---|

| Ukuphuka kwe-Fiber | Amandla e-shear ku-matrix encibilikisiwe aholela ekuqhekekeni kwefayibha, okuthinta izakhiwo zesakhiwo somkhiqizo wokugcina. |

| Isizukulwane Sokushisa | Cishe u-80% wokushisa odingekayo ukuze uncibilike ukhiqizwa ukungqubuzana ngenxa yokugunda phakathi kwezikulufu kanye nomgqomo. |

| Ukuxuba Ukusebenza kahle | Idizayini yezindawo zokuxuba ezinezinto ezidlulisela phambili nangemuva zithonya amandla okucindezela kanye nokusebenza kahle kokuhlanganisa. |

| Ukusabalalisa Isikhathi Sokuhlala | I-RTD ithinta kakhulu izici zomkhiqizo ngokunquma isikhathi sokuchayeka kumazinga okushisa, ingcindezi, nokugunda. |

Ukwengeza, ukukhulisa isivinini se-rotor ngesikhathi sokuxutshwa kwe-polypropylene-sisasal melt-mixing kuphumela ekuqhekekeni kwefayibha okwengeziwe, kukhiqizwe ubude befiber emincane. Lesi simo, esibonwa emiculweni yemvelo, senzeka ngoba i-shear ihlukanisa imicu ehlanganisiwe, inciphisa ububanzi bayo. Lokhu okutholakele kugcizelela ukubaluleka kokuthuthukisa amandla e-shear ukulinganisa ukusebenza kahle kokuxuba kanye nobuqotho bezinto ezibonakalayo.

Umthelela Ezimpahleni Ezishisayo Nokusabalalisa Ukushisa

Amandla e-Shear athonya kakhulu izakhiwo ezishisayo kanye nokusabalalisa ukushisa ngesikhathi sokukhipha. Ukungqubuzana okukhiqizwa izikulufu kubala cishe u-80% wokushisa okudingekayo ukuze kuncibilike izinhlanganisela zepulasitiki. Lokhu kusatshalaliswa kokushisa kuqinisekisa ukuncibilika okufanayo futhi kuvimbela ukushisa okweqile kwendawo, okungehlisa izinga lempahla.

Idizayini yezindawo zokuxuba ze-extruder ithuthukisa ngokwengeziwe ukudluliswa kokushisa. Ama-elementi adlulisa phambili nakahlehla adala amandla okucindezela athuthukisa ukusebenza kwe-thermal. Ukusatshalaliswa kwesikhathi sokuhlala (RTD) nakho kudlala indima ebalulekile. Izinto ezivezwe kumandla okugunda okungaguquki zithola ukushisa okufanayo, okuholela ekuzinzeni okungcono kokushisa.

Isibonelo, ukulingiswa kwezinombolo kuveza ukuthi amandla okugunda athinta i-microstructure yama-alloys angabonakali ngesikhathi sokuxutshwa. Lawa mandla athonya izilinganiso ze-viscosity kanye nesiyaluyalu, aqinisekise ngisho nokusatshalaliswa kokushisa kuyo yonke into. Ukuthola okunjalo kugqamisa ukubaluleka kwamandla e-shear ekugcineni ukulingana okushisayo ngesikhathi sokukhipha.

Izinguquko Ezimpahleni Zemishini namandla Wezinto ezibonakalayo

Amandla e-Shear athinta ngokuqondile izakhiwo zemishini namandla ezinto ezikhishwe. Ukwehluka kokuqina kwe-shear kungashintsha ukwakheka kwamangqamuzana, okuholela ekushintsheni kwamandla aqinile, ukunwebeka, nokuqina.

Ucwaningo lwezinombolo lubonisa le miphumela:

- Amandla okusheya aphezulu wezibonelo zamajoyinti e-engeli eguquguqukayo akhuphuka ngokungahambisani nengcindezi evamile, kuyilapho amandla okusheya ayinsalela abonisa ukuhlobana okuncane nokuma kwamalunga.

- Ngengcindezi evamile ephansi, izibonelo zibonisa i-shear dilatancy, eyancipha emazingeni aphezulu okucindezeleka. Lokhu kuziphatha kubonisa ukuhlobana okungekuhle phakathi kokugudluzwa okuvamile kanye ne-tangential.

- Izici zokwehluleka ziyahlukahluka ngama-engeli ahlangene. Izindawo ezine-engeli ephezulu zibonisa imifantu eqondile kanye ne-shear, kuyilapho izindawo ezine-engeli ephansi zibonisa ukwehluleka kokugunda eduze kwendlela yokugunda.

Lokhu okutholakele kugcizelela isidingo sokulawula amandla okugunda ukuze kuzuzwe izakhiwo ezifiselekayo zemishini. Isibonelo, ukugunda ngokweqile kungabangela ukuphuka kwe-fiber, ukunciphisa amandla ezinto ezibonakalayo. Ngokuphambene, ukugunda okunganele kungase kubangele ukuxubana okungaphelele, kubeke engcupheni ikhwalithi yomkhiqizo.

Izibonelo: Ukuziphatha Kwempahla Ngaphansi Kwezimo Eziguquguqukayo Zokugunda

Izibonelo zezifundo zinikeza ukuqonda okubalulekile kokuthi amandla okugunda akuthinta kanjani ukuziphatha okubonakalayo. Ucwaningo lwe-polypropylene-clay nanocomposites lubonisa lokhoama-twin screw extrudersfinyelela ukuhlakazeka okuphezulu uma kuqhathaniswa nezinhlelo zesikulufa esisodwa. Amandla e-shear ephakeme athuthukisa ukucwenga, ukuthuthukisa izakhiwo zemishini nezokushisa.

Olunye ucwaningo lwemicu yemvelo lwembula ukuthi ukugunda okufakwe phakathi nokuhlanganisa kuyahlukanisa imicu ehlanganisiwe, kunciphisa ububanzi bayo. Le nqubo ithuthukisa ukufana kwento kodwa ingase ibeke engcupheni ubuqotho bayo besakhiwo.

Ezisetshenziswa zezimboni, ukuqinisa amandla e-shear kufakazele ukuthi kubalulekile ekukhiqizeni imikhiqizo yekhwalithi ephezulu. Isibonelo, ukulungisa isivinini sesikulufu kanye nejiyomethri ku-plastic twin screw extruder kuqinisekisa ukuxutshwa okufanayo kanye nezakhiwo zempahla ezingaguquki. Lezi zibonelo zezifundo zigqamisa ukubaluleka kokuhlanganisa amandla okugunda ukuze ahambisane nezinhlelo ezithile zokusebenza.

Amasu Okuthuthukisa E-Plastic Twin Screw Extruder

Idizayini yesikulufu kanye nokulungiswa kokucushwa

Ukuthuthukisa ukwakheka kwesikulufakubalulekile ekuthuthukiseni ukusebenza kwe-plastic twin screw extruder. Ukulungiswa kwesikulufi sejiyomethri, njengokuphakama kwendiza, ukujula kwendiza, ne-engeli ehlanganayo, kuthonya ngokuqondile ukukhiqizwa kwe-shear force nokugeleza kwempahla. Isibonelo, izikulufu ezinezindiza ezijulile zinciphisa ukuqina kwe-shear, kuyilapho ama-engeli ahlanganayo aqinile athuthukisa ukusebenza kahle kokuhlanganisa.

Ama-opharetha ngokuvamile enza ngendlela oyifisayo ukucushwa kwesikulufu ukuze kufane nezakhiwo ezibonakalayo ezithile. Amapulasitiki ane-viscosity ephezulu azuza kuzikulufu eziklanywe ngokujula okukhulu kwendiza ukuze kube lula ukugeleza okushelelayo. Ngokuphambene, izinto ze-viscosity ephansi zidinga ama-engeli ahlanganayo aqinile ukuze kuqinisekiswe ukugunda okwanele. Lokhu kulungiswa kuthuthukisa i-homogeneity yezinto futhi kunciphise ukusetshenziswa kwamandla ngesikhathi sokukhipha.

Ukulinganisa Amandla e-Shear kanye Nezinga Lokushisa

Ukugcina ibhalansi phakathi kwamandla okugunda nezinga lokushisa kubalulekile ukuze kuzuzwe ikhwalithi ye-extrusion engaguquki. Amandla okugunda okweqile angaholela ekushiseni ngokweqile, kuyilapho ukugunda okunganele kungase kubangele ukuxubana okungaphelele. Ukuphatha ingcindezi ngaphakathi kwe-extruder kudlala indima ebalulekile ekulawuleni lokhu okuguquguqukayo.

Isibonelo, ifomula ibonisa ukuhlobana phakathi kwengcindezi nezinga lokushisa: ∆T (°C) = ∆P (ibha) ÷ 2. Ukucubungula u-500 kg/hr ngomfutho we-die of 40 bar kungakhuphula izinga lokushisa elincibilikayo cishe ngo-20°C. Ukuhlanganisa iphampu yegiya kunciphisa ukucindezelwa kokukhipha, kunciphisa izinga lokushisa nokuguga kuzikulufu zokukhipha. Ukulawula ukucindezela kwe-loop evaliwe kuthuthukisa futhi ukuzinza kwe-extrusion, kuqinisekisa ukusatshalaliswa kokushisa okufanayo kanye nezakhiwo ezifanele zempahla.

I-Tailoring Shear Force for Specific Plastic Application

Ukuhlanganisa amandla okugunda ukuze kusetshenziswe izinto ezithile kuthuthukisa ukusebenza kwezinto zepulasitiki. Isibonelo, ukungeza ama-plasticizers ku-PLA composite kuthuthukisa ukuguquguquka, ukumelana nomthelela, kanye nezakhiwo zemishini. Izithombe ze-Scanning electron microscopy (SEM) ziveza ukuthi i-PLA eyenziwe ngepulasitiki ibonisa i-ductility enkulu uma iqhathaniswa nezinhlanganisela ezingenapulasitiki, ezibonisa ukuziphatha okuxegayo.

Ukuhlolwa kwe-Flexural kubonisa ukuthi izinhlanganisela zepulasitiki zinamanani aphansi e-flexural modulus, okubonisa ukuguquguquka okukhulayo. Ukwengeza, ukungezwa kwama-plasticizers kunciphisa izinga lokushisa lokushintsha kwengilazi (Tg), okwenza kube lula ukucubungula. Lokhu kulungiswa kugqamisa ukubaluleka kokwenza ngokwezifiso amandla e-shear ukuze kuhlangatshezwane nezidingo ezihlukile zezicelo zepulasitiki ezihlukene.

Amasu Okuqapha Nezilinganiso Zesikhathi Sangempela

Amasistimu wokuqapha wesikhathi sangempelahlinzeka ngemininingwane ebalulekile enqubweni ye-extrusion, okuvumela opharetha ukuthi bathuthukise amandla e-shear ngempumelelo. Izinzwa zikala amapharamitha angukhiye afana nezinga lokushisa, ingcindezi, netorque, enikeza ukulawula okunembayo kuzimo ze-extrusion.

Amasu okuqapha athuthukile, njengamasistimu avaliwe, agcina izilungiselelo zengcindezi engaguquki futhi avimbele ukuguquguquka okungafaka engcupheni ikhwalithi yomkhiqizo. Lawa masistimu aphinde athole okudidayo ekugelezeni kwezinto, okuvumela opharetha ukuthi benze izinguquko ngokushesha. Ngokusebenzisa idatha yesikhathi sangempela, abakhiqizi baqinisekisa ukuthi i-plastic twin screw extruder isebenza kahle kakhulu, iletha okukhiphayo kwekhwalithi ephezulu.

Amandla e-Shear ahlala eyitshe legumbi le-plastic twin screw extrusion, ukubumba izinto ezibonakalayo njengokuxubana, ukuzinza kwe-thermal, namandla emishini. Ukuthuthukisa la mandla kuthuthukisa ikhwalithi yomkhiqizo nokusebenza kahle kwenqubo.

Ukuqamba okusha okuqhubekayo ekulawuleni amandla e-shear kuzovula amathuba amasha ekucutshungulweni kwepulasitiki. Abacwaningi nonjiniyela kufanele bahlole amasu athuthukile ukuze bacwengisise imiphumela ye-extrusion ngokuqhubekayo.

FAQ

Uyini umsebenzi oyinhloko wamandla e-shear ku-twin screw extrusion?

Amandla e-Shear asiza ukuncibilika kwezinto, ukuxubana, kanye ne-homogenization. Iqinisekisa ikhwalithi yomkhiqizo engaguquki ngokuthonya izakhiwo ezishisayo nezomshini ngesikhathi sokukhipha.

Opharetha bangawalawula kanjani amandla e-shear ku-twin screw extruder?

Ama-opharetha alungisa isivinini sesikulufu, enze ngendlela oyifisayo ijiyomethri yesikulufu, futhi aqaphe amapharamitha esikhathi sangempela njengokucindezela netorque ukuze alawule amandla okugunda kahle.

Kungani ukulinganisa amandla okugunda kanye nezinga lokushisa kubalulekile?

Ukulinganisa amandla okugunda kanye nezinga lokushisaivimbela ukuwohloka kwempahla, iqinisekisa ukuxutshwa okufanayo, futhi igcina izimo ezingcono kakhulu zokukhipha umkhiqizo wekhwalithi ephezulu.

Isikhathi sokuthumela: Jun-11-2025