Umshini wokubumba umjovo wepulasitiki uguqula kahle ipulasitiki eluhlaza ibe yizimo ezinembile, eziyinkimbinkimbi. Le nqubo inikeza izinzuzo eziphawulekayo:

- Ukukhiqiza izingxenye eziyinkimbinkimbi ngokunemba okuphezulu kwe-dimensional.

- Ukuletha ikhwalithi engaguquki nokuphindaphinda.

- Ukunciphisa izindleko zokukhiqiza ekukhiqizeni okukhulu.

Imiklamo ethuthukisiwe, njengomshini wokubumba umjovo wohlobo lweScrew kanyeUmshini Wokubumba Umjovo Wohlobo Lwezikulufu, thuthukisa ukugeleza kwezinto futhi uthuthukise ukusebenza. Ngaphezu kwalokho, i-Umshini Wokubumba Umjovo Ophindwe KabilifuthiUmshini Wokubumba Umjovo wesikulufuukuthuthukisa ukusebenza kahle kanye nokuphumayo ohlelweni lokukhiqiza.

Iyunithi Yomjovo Emshinini Wokubumba Umjovo Wohlobo Lwe-Screw

Iyunithi yomjovo Emshinini Wokubumba Umjovo Wohlobo Lwe-Screw idlala indima ebalulekile ekuguquleni ama-pellets epulasitiki aluhlaza abe yisimo esincibilikisiwe futhi awajove esibunjeni. Le yunithi iqukethe izingxenye ezintathu eziyinhloko: i-hopper, i-barrel, ne-screw mechanism. Ingxenye ngayinye inomthelela ekusebenzeni kahle nasekunembeni kwenqubo yokubumba.

I-Hopper

I-hopper isebenza njengendawo yokungena yezinto zepulasitiki ezingavuthiwe. Ibamba ama-pellets epulasitiki bese iwaphakela emgqonyeni ukuze kuqhutshekwe nokucubungula. Ama-hopper esimanje ngokuvamile afaka izici ezifana nezinhlelo zokomisa izinto ezisetshenziswayo ukuze kususwe umswakama kuma-pellets, kuqinisekiswe ikhwalithi ephezulu yokuncibilika. Ngokugcina ukunikezwa okungaguquguquki kwezinto, i-hopper isekela imijikelezo yokukhiqiza engaphazamiseki kumshini Wokubumba Umjovo Wohlobo Lwe-Screw.

Umgqomo

Umgqomo uyigumbi eliyicylindrical elihlala umshini wesikulufu. Ishisisa ama-pellets epulasitiki endaweni yawo yokuncibilika kusetshenziswa izindawo zokushisisa eziningi. Lawa mazoni—ngokuvamile ahlukaniswa abe okuphakelayo, ngemuva, okuphakathi, nangaphambili—avumela ukulawulwa okunembile kwezinga lokushisa, okubalulekile ekuzuzeni ikhwalithi efanayo yokuncibilika. Ukusatshalaliswa kwezinga lokushisa okulungile ngaphakathi komgqomo kuvimbela izinkinga ezifana ne-warpage, ukungalungi kwe-dimensional, nokuwohloka kwezinto. Lokhu kulawula okucophelela kuqinisekisa ukuthi Umshini Wokubumba Umjovo Wohlobo LweScrew uletha okukhiphayo kwekhwalithi ephezulu ngokungashintshi.

- Izinga lokushisa elifanele lendawo yomgqomo libalulekile ekusebenzeni kahle.

- Izilungiselelo ezingalungile zingaholela ekulimaleni komkhiqizo wokugcina.

- Imiklamo ethuthukisiwe ithuthukisa ukusebenza kahle kwamandla futhi inciphise izindleko zokusebenza.

I-Screw Mechanism

I-screw mechanism yinhliziyo yeyunithi yomjovo. Izungeza ngaphakathi komgqomo, ixube futhi incibilikise ama-pellets epulasitiki ngenkathi iphusha into encibilikisiwe phambili. Idizayini yesikulufu inomthelela omkhulu ekuncibilikeni nasekujovweni. Ngokwesibonelo, umileimiklamo isikulufathuthukisa ipulasitiki ngokuqinisekisa ukuchayeka kwe-shear okungaguquki kanye nevolumu yokudubula. Ukwengeza, izici ezifana nama-poppet valves zinikeza ukulawula okunembile ngokuvala ngokushesha lapho isikulufu sima.

EMishini Yokubumba Yohlobo Lwe-Screw Kagesi yonke, i-screw mechanism inikeza ukulawula okungenakuqhathaniswa phezu kwesivinini, ingcindezi, nokuma. Lokhu kunemba kunciphisa ukuhluka phakathi kwemijikelezo, iqinisekisa amanani okugcwalisa angaguquki namasayizi okudutshulwa. Lokhu kuthuthukiswa akuthuthukisi ikhwalithi yokuncibilika kuphela kodwa futhi kuthuthukisa ukusebenza kahle okuphelele kwenqubo yokubumba.

- Ukuhlanganiswa kwe-automation kanye namarobhothi kuqhubeza nokuthuthukisa umkhiqizo wokukhiqiza.

- Imiklamo yezikulufo ezonga amandla inomthelela ekongeni izindleko.

- Ukusetshenziswa okuzinzile kwempahla kuhambisana nezinqubo zesimanje zokukhiqiza.

Iyunithi yomjovo Emshinini Wokubumba Umjovo Wohlobo Lwe-Screw liyisibonelo sokusebenzisana kobunjiniyela obuthuthukisiwe nokulawula ukunemba. Izingxenye zayo zisebenza ndawonye ngaphandle komthungo ukuze zilethe ukukhiqizwa kwekhwalithi ephezulu, okuphumelelayo, nokwethembekile.

Amayunithi Okuqinisa kanye Nesikhunta

Amayunithi okubamba kanye nesikhunta ayingxenye ebalulekile yomshini wokubumba umjovo wepulasitiki. Baqinisekisa ukuthi isikhunta sihlala sivaliwe ngokuvikelekile ngesikhathi sokujova futhi kusiza ukwakheka kwezingxenye ezinembile, ezisezingeni eliphezulu. Lawa mayunithi ahlanganisa isikhunta, amapuleti, kanye nokushayela kwezimoto, ngalinye lidlala indima ehlukile enqubweni yokubumba.

Isikhunta

Isikhunta sisebenza njengendawo lapho ipulasitiki encibilikisiwe ibumbeka khona. Ukwakheka kwayo kunomthelela ngqo kwikhwalithi nokuvumelana komkhiqizo wokugcina.Imikhuba emihle kakhulu ekwakhiweni kwesikhuntagcizelela ukujiya kodonga olufanayo ukuze kuvikelwe amaphutha afana nezimpawu zokuguquguquka nokucwila ngesikhathi sokupholisa. Ukushintsha okushelelayo phakathi kogqinsi obuhlukahlukene, okufinyelelwa ngama-chamfers noma ama-fillets, kuqhubekisela phambili ukuthuthukisa ubuqotho besakhiwo.

- Ugqinsi olufanele lodonga lugwema amaphutha ezimonyo njengokuwohloka nokucwila.

- Amandla esakhiwo angathuthukiswa ngezimbambo nama-gussets esikhundleni sokukhulisa ukujiya.

- Amasu e-Design of Experiments (DOE) asiza ekuboneni amaphutha kusenesikhathi, aqinisekise ukusebenza kahle nokuthembeka.

Emshinini Wokubumba Umjovo Wohlobo Lwe-Screw, ukunemba kwesikhunta kuqinisekisa ukuthi imiklamo eyinkimbinkimbi nokubekezelelana okuqinile kuyafezeka. Leli khono liyenza ilungele ukukhiqiza izingxenye eziyinkimbinkimbi ezinekhwalithi engaguquki.

Amapuleti

Amapuleti amapuleti amakhulu, ayisicaba abamba isikhunta endaweni futhi asabalalisa amandla okubamba ngokulinganayo. Idizayini yabo nobuqotho besakhiwo kubalulekile ekugcineni ukuhambisana kwesikhunta nokuqinisekisa ingcindezi efanayo ngesikhathi sokujova. Amapharamitha angukhiye ezobuchwepheshe anomthelela ekusebenzeni kahle kwe-platen afaka umthelela wesisindo, umthamo wokuthwala umthwalo, nokwenza kahle kwesakhiwo.

| Ipharamitha | Umthelela Ekuqondeni Kwesikhunta |

|---|---|

| Umthelela Wesisindo | Yakha cishe u-70% wesisindo esiphelele somshini, okuthinta ukuzinza nokuhleleka. |

| Ukubaluleka Kwezomnotho | Ukuthuthukisa idizayini kunciphisa ukusetshenziswa kwezinto ezingavuthiwe, kuthuthukisa ukusebenza kahle kwezindleko. |

| Umthelela Wokusebenza | Iqinisekisa ukuqondana okufanele kwesikhunta kanye nokusabalalisa ingcindezi efanayo, okubalulekile ekukhiqizeni kwekhwalithi ephezulu. |

| Ukuthuthukiswa Kwesakhiwo | Ithuthukisa usayizi, umumo, nokusatshalaliswa kwezinto ezibonakalayo ukuze kuqondiswe kangcono. |

| Ikhono Lokuthwala | Ithuthukisa ukuqina futhi isekele ukuqondana kwesikhunta ngaphansi kwengcindezi yokusebenza. |

Emshinini Wokubumba Umjovo Wohlobo Lwe-Screw, amapuleti anikela ekhonweni lomshini lokukhiqiza izingxenye ezinokunemba okuphezulu kobukhulu. Idizayini yabo eqinile iqinisekisa ukuqina nokusebenza okungaguquguquki, ngisho nangaphansi kwamandla aphezulu okubamba.

I-Motor Drive

I-motor drive inika amandla indlela yokubopha, ivumela isikhunta ukuthi sivuleke futhi sivale ngokunemba. Idlala indima ebalulekile ekugcineni ijubane nokunemba kwenqubo yokubopha.Izithuthuthu zesimanje, ikakhulukazi kumishini kagesi wonke, inikeza ukulawula okuthuthukisiwe phezu kwamandla okubamba kanye nokuma. Lokhu kunemba kunciphisa ukuguga esikhunjeni futhi kunciphisa izikhathi zomjikelezo, kuthuthukisa ukusebenza kahle konke.

Imishini eyonga amandla nayo inomthelela ekongeni izindleko kanye nokusimama. Ngokuthuthukisa ukusetshenziswa kwamandla, zihambisana nezinqubo zesimanje zokukhiqiza ezibeka phambili umthwalo wemfanelo wendawo. Emshinini Wokubumba Umjovo Wohlobo LweScrew, idrayivu yemoto iqinisekisa ukusebenza okungenamthungo, isekela ukukhiqizwa kwesivinini esikhulu ngaphandle kokubeka engcupheni ikhwalithi.

Ithiphu:Ukugcinwa okuvamile kwe-motor drive kunganweba isikhathi sayo sokuphila futhi kuvimbele ukuphumula okungalindelekile, kuqinisekise ukukhiqizwa okungaphazamiseki.

Amayunithi okubamba kanye nesikhunta ayisibonelo sokusebenzisana kobunjiniyela nokunemba emshinini wokubumba umjovo wepulasitiki. Ukuklama nokusebenza kwawo kuthonya ngokuqondile ikhono lomshini lokukhiqiza izingxenye zekhwalithi ephezulu ngendlela ephumelelayo futhi enokwethenjelwa.

Amasistimu Wokulawula Ukushisa Nokushisa

Ukushisa okusebenzayo kanye nezinhlelo zokulawula izinga lokushisa kubalulekile ukuze kugcinwe ikhwalithi nokuvumelana kwezinqubo zokubumba umjovo wepulasitiki. Lezi zinhlelo ziqinisekisa ukuthi izinto zepulasitiki zifinyelela endaweni efanele yokuncibilika nokuthi izinga lokushisa lesikhunta lihlala lizinzile kuwo wonke umjikelezo.

Izifudumezi Zemigqomo

Izifudumezi zemiphongolodlala indima ebalulekile ekuncibilikiseni ama-pellets epulasitiki ekushiseni kwawo okuphezulu. Basebenzisa izindawo zokushisisa eziningi ukuze bathole ukulawulwa kwezinga lokushisa okunembile, okubalulekile kwikhwalithi efanayo yokuncibilika. Ukulawulwa kwezinga lokushisa okuphumelelayo kuthuthukisa ukusebenza kahle kwamandla futhi kuthuthukisa ukuphela kwezingxenye ezibunjiwe.

- Ukulawula kahle izinga lokushisa lomgqomo kuvimbela ukuwohloka kwezinto, ikakhulukazi ngezikhathi zokuhlala ezinwetshiwe.

- Ukugcina izinga lokushisa eliqondiwe lokuncibilika cishe elingu-490°F kuqinisekisa ukugeleza kwezinto ezingaguquki futhi kunciphisa amaphutha.

- Ukushintshashintsha kwezinga lokushisa lomgqomo kungaba nomthelela omubi kwikhwalithi yomkhiqizo, okwenza ukuqapha okuseduze kubaluleke kakhulu.

Imiklamo ethuthukisiwe yemiphongolo ngokuvamile ihlanganisa izinto zokushisisa ezonga amandla, ehlisa izindleko zokusebenza kuyilapho igcina ukusebenza okuphezulu. Lezi zici zihambisana nezinqubo zesimanje zokukhiqiza ezibeka phambili ukusimama nokusebenza kahle.

Izifudumezi Zesikhunta

Izifudumezi zesikhunta zilawula izinga lokushisa lesikhunta, ziqinisekisa ikhwalithi yengxenye engashintshi kanye nokunciphisa izikhathi zokujikeleza. Ubukhulu bezinto zokubumba buthinta kakhulu amazinga okudlulisa ukushisa. Izingxenye eziwugqinsi zigcina ukushisa isikhathi eside, kuyilapho izingxenye ezincanyana ziphola ngokushesha. Ukulungisa izilungiselelo ze-heater yesikhunta ngokusekelwe ekugqineni kwempahla kuvimbela izinkinga ezifana ne-warping futhi kuqinisekisa ukusatshalaliswa kwezinga lokushisa okufanayo.

Izindlela Zokubumba Zesayensi ziqhubeka nokuthuthukisa ukusebenza kwe-heater yesikhunta. Lezi zindlela zinciphisa izikhathi zokuqalisa, zehlise amanani okulahlwa, futhi zithuthukise ukungaguquguquki kwenqubo. Ngokugcina izinga lokushisa elinembile lesikhunta, abakhiqizi bathola inzuzo ephezulu nokusebenza kahle.

I-Temperature Control Mechanism

Iindlela yokulawula izinga lokushisaiqinisekisa ukuzinza nokunemba phakathi nenqubo yokubumba. Amasu athuthukile, njengokulawula okungaqondakali okulungisekayo ochwepheshe, ahlanganisa ukulawula kwe-PID okungokwesiko nokucabanga okungaqondakali ukuze kulungiselelwe izinga lokushisa lomgqomo. Le ndlela inciphisa ukudubuleka nokuzulazula, ithuthukise ukusebenza kohlelo lonke.

| Isu Lokulawula | Incazelo |

|---|---|

| Ukulawula Okungaqondakali Okuguquguqukayo Uchwepheshe | Ihlanganisa ukulawula kochwepheshe, okungaqondakali, kanye ne-PID ukuze uthole ukuzinza nokunemba okuthuthukisiwe. |

| Ukulawulwa kwe-PID | Indlela yendabuko ethambekele ekudubuleni ngokweqile kanye ne-oscillation. |

| Imodeli Yokulawula Ukubikezela | Ilandelela ijubane lomjovo, ithuthukisa ukunemba ezinqubweni zokubumba. |

Amamodeli okufunda ngomshini, njengama-algorithms ehlathi angahleliwe, nawo anikela ekusebenzeni kahle kwamandla ngokuhlonza izinto ezibalulekile ezithinta ukusetshenziswa kwamandla. Lezi zinto ezintsha zisiza abakhiqizi ukuthi balinganisele ukusetshenziswa kwamandla nengxenye yekhwalithi, kuthuthukise ngokwengeziwe ukusimama kokusebenza kokubumba umjovo.

Amayunithi we-Hydraulic and Control

I-hydraulic kanye namayunithi okulawula ayizingxenye ezibalulekile zomshini wokubumba umjovo wepulasitiki. Lezi zinhlelo zisebenza ndawonye ukuze kuqinisekiswe ukusebenza okunembayo, ukusebenza kahle, kanyeizinga lomkhiqizo elingaguquki.

IHydraulic System

Uhlelo lwe-hydraulic lunika amandla ukunyakaza komjovo kanye nezindlela zokubopha. Ikhiqiza amandla adingekayo ukujova ipulasitiki encibilikisiwe esikhunjeni futhi igcine ingcindezi yokubopha ngesikhathi sokubumba. Amaphampu we-hydraulic, ama-valve, namasilinda akha umnyombo walolu hlelo, aletha ukusebenza okulawulwayo nokuthembekile.

Amasistimu we-hydraulic wesimanje ahlanganisa ubuchwepheshe obuthuthukisiwe ukuzeukuthuthukisa ukusebenza kahle. Amaphampu ashintshashintshayo alungisa izinga lokugeleza ngokusekelwe ezidingweni zokusebenza zomshini, ehlisa ukusetshenziswa kwamandla. Ukwengeza, ama-valve alinganayo ahlinzeka ngokulawula okunembile phezu kokucindezela nokugeleza, ukuqinisekisa ukunyakaza okubushelelezi nokunembile. Lezi zici zifaka isandla ekhonweni lomshini lokukhiqiza izingxenye zekhwalithi ephezulu ezinodoti omncane.

Ithiphu:Ukunakekelwa okuvamile kwezingxenye ze-hydraulic, njengokuhlola ukuvuza nokuqapha ikhwalithi kawoyela, kunganweba ubude bempilo yesistimu futhi kuvimbele ukungasebenzi.

Iphaneli yokulawula

Iphaneli yokulawula isebenza njengobuchopho bomshini wokubumba umjovo. Iqapha futhi ilawule yonke imisebenzi yomshini, iqinisekisa ukusebenza kahle. Ifakwe izinzwa, iphaneli yokulawula iqoqa idatha yesikhathi sangempela kumapharamitha abalulekile njengezinga lokushisa, ukucindezela, nesimo. Ngokwesibonelo:

- Izinzwa ziyakala futhi zinikeze impendulo ngezinga lokushisa nokucindezela.

- Izinzwa ze-membrane eyindandatho ziqinisekisa izilinganiso zokuma okunembile zisebenzisa amaseli egeji yobunzima.

Amamodeli okufunda omshini ahlanganiswe kuphaneli yokulawula athuthukisa futhi amandla ayo. Lawa mamodeli abikezela ingxenye yamapharamitha wekhwalithi efana nengcindezi ye-yield kanye ne-modulus, ilungiselela izilungiselelo zenqubo ukuze uthole imiphumela engaguquki. Okutholwe kokuhlolwa kuqinisekisa la mamodeli ngokuqhathanisa amanani abikezelwe nemiphumela yangempela, okuqinisekisa ukusebenza kahle kwawo ekuthuthukiseni ukusebenza kahle kokukhiqiza.

I-hydraulic kanye namayunithi okulawula ayisibonelo sokusebenzisana kobuchwepheshe bemishini nedijithali, iqinisekisa ukunemba nokuthembeka emishinini yokubumba umjovo wepulasitiki.

Izindlela Zokuphakela Nezokukhipha

Iyunithi Yokudla

Iiyunithi yokudlaiqinisekisa ukunikezwa okungaguquki kwezinto zepulasitiki ezingavuthiwe emshinini wokubumba umjovo. Ngokuvamile iqukethe i-hopper kanye nesikulufu sokudla. I-hopper igcina ama-pellets epulasitiki futhi iwaqondise emgqonyeni, lapho izinto zincibilika khona. Amandla adonsela phansi kanye nokudlidliza okulawulwayo kusiza ukugeleza okushelelayo kwama-pellets, kuvimbele ukuvinjelwa noma ukuphazamiseka ngesikhathi sokukhiqiza.

Amayunithi okuphakelayo esimanje ngokuvamile ahlanganisa izici ezithuthukile njengamasistimu okomisa impahla. Lezi zinhlelo zisusa umswakama kuma-pellets, okubalulekile ekugcineni izinga lokuncibilika nokuvimbela ukukhubazeka emkhiqizweni wokugcina. Ukwengeza, izindlela zokuphakela ezizenzakalelayo zithuthukisa ukusebenza kahle ngokuvumelanisa ukunikezwa kwezinto nesivinini sokusebenza komshini. Lokhu kuvumelanisa kunciphisa ukumoshakala kwezinto futhi kuqinisekisa imijikelezo yokukhiqiza engaphazamiseki.

Iyunithi yokukhipha

Iiyunithi yokukhiphaidlala indima ebalulekile ekususeni ingxenye ebunjiwe emgodini wesikhunta ngemva kokupholisa. Isebenzisa izikhonkwane ze-ejector, amapuleti, noma ukuqhuma komoya ukuze ikhulule umkhiqizo oqediwe ngaphandle kokudala umonakalo. Ukunemba kusikhathi sokukhipha kanye namandla kubalulekile ukuze kugcinwe ubuqotho bengxenye ebunjiwe futhi kuvinjwe amaphutha afana nokungqubuzana noma ukuqhekeka.

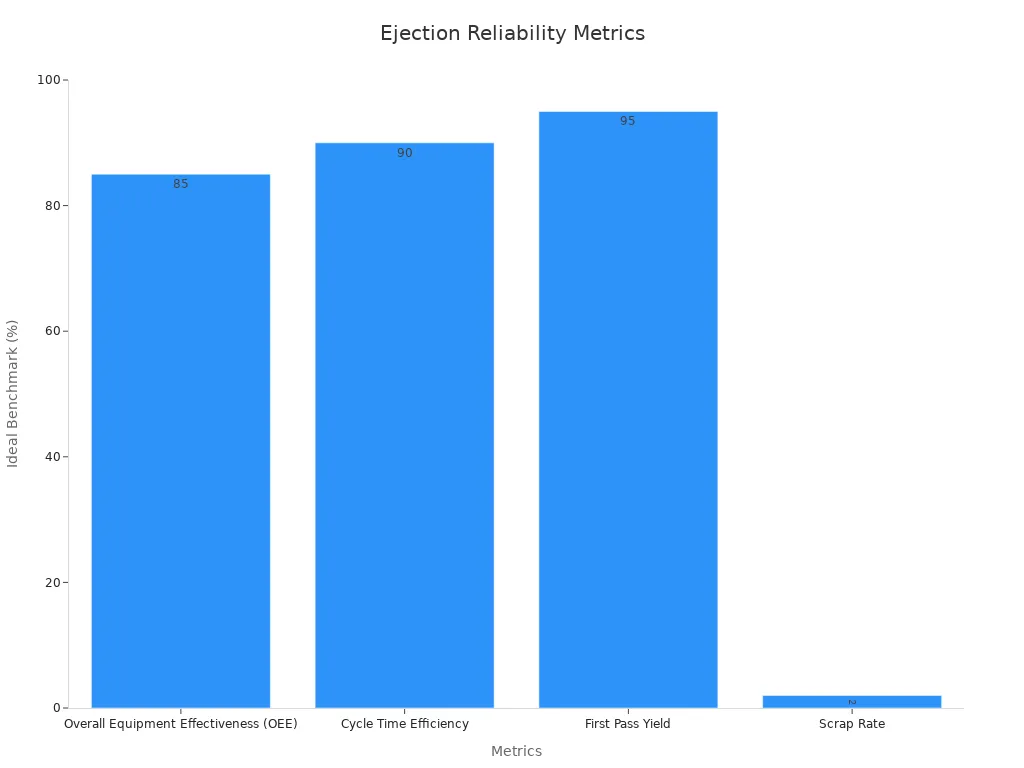

Amayunithi okukhipha athembekile anciphisa kakhulu izikhathi zokwehla komjikelezo wokukhiqiza. Amamethrikhi afana ne-Oall Equipment Effectiveness (OEE), Cycle Time Efficiency, kanye ne-First Pass Yield (FPY) aqinisekisa ukusebenza kwawo. Ngokwesibonelo:

| Imethrikhi | Incazelo | Ibhentshimakhi ekahle |

|---|---|---|

| Ukusebenza Kwesisetshenziswa Kukonke (OEE) | Ikala ukusebenza kahle kokukhiqiza; kubalwe kusukela ekutholakaleni, ukusebenza, kanye nekhwalithi. | ~85% |

| Ukusebenza Kwesikhathi Somjikelezo | Ilandelela isikhathi sokuqeda umjikelezo wokukhiqiza owodwa; izikhathi eziphansi zithuthukisa ukuphuma. | 90% noma ngaphezulu |

| I-First Pass Yield (FPY) | Iphesenti lemikhiqizo eyenziwe ngendlela efanele okokuqala; amanani aphezulu akhombisa izinqubo ezisebenzayo. | >95% |

| Izinga leScrap | Iphesenti lezinto ezilahliwe; amanani aphansi athuthukisa inzuzo. | <2% |

Amasistimu okukhipha athuthukile ahlanganisa izinzwa ukuze ziqaphe futhi zilungise amandla okukhipha ngokuguquguqukayo. Lezi zinto ezintsha ziqinisekisa ikhwalithi yengxenye engaguquki kuyilapho kunciphisa ukuguga kwesikhunta nezingxenye zomshini. Ukugcinwa okuvamile kweyunithi yokukhipha i-ejection kuthuthukisa futhi ukuthembeka kwayo futhi kwandisa isikhathi sayo sokusebenza.

Umshini wokubumba umjovo wepulasitiki uhlanganisa izingxenye ezithuthukile ukuze ulethe ukusebenza okukhethekile. Ingxenye ngayinye inomthelela ekusebenzeni kahle kokukhiqiza, ikhwalithi, nokwethembeka. Ukwenza kahle lezi zinhlelo kuqinisekisa imiphumela emihle.

| Imethrikhi | Incazelo |

|---|---|

| Ukukhiqiza Ngempumelelo | Ibonisa ukuthi izinto zokusetshenziswa ziguqulwa kanjani zibe imikhiqizo eqediwe. |

| Izinga leScrap | Ibonisa iphesenti lokukhiqiza elingahlangabezani namazinga ekhwalithi. |

| Isikhathi sokuphumula somshini | Kunomthelela ekusebenzeni kahle kokukhiqiza kanye nezindleko zokusebenza, okubalulekile ekwenzeni inzuzo. |

Ukuqonda lawa mamethrikhi kugqamisa indima yomshini ekuzuzeni umphumela ofanayo, wekhwalithi ephezulu.

FAQ

1. Yiziphi izinto ezingasetshenziswa emshinini wokubumba umjovo wepulasitiki?

Imishini yokubumba yomjovo wepulasitiki icubungula ama-thermoplastics afana ne-ABS, i-polypropylene, nenayiloni. Baphinde baphathe amapulasitiki obunjiniyela njenge-polycarbonate ne-PEEK.

2. Ukulawula izinga lokushisa kuthinta kanjani ikhwalithi yomkhiqizo?

Ukulawula izinga lokushisa okunembile kuqinisekisa ikhwalithi efanayo yokuncibilika, kunciphisa amaphutha, futhi kuthuthukise ukunemba kobukhulu. Ivimbela ukuwohloka kwezinto phakathi nemijikelezo yokucubungula eyandisiwe.

3. Yiziphi izindlela zokulungisa ezithuthukisa ukusebenza komshini?

Ukugcotshwa okuvamile, ukuhlolwa kwesistimu ye-hydraulic, nokuhlanza amayunithi okuphakelayo kuvimbela ukuguga nokuncipha kwesikhathi. Izinzwa zokuqapha ziqinisekisa ukusebenza okungaguquki futhi kwelula ubude besikhathi sokuphila komshini.

Isikhathi sokuthumela: May-28-2025