Ngiyethemba i-PVC Pipe screw barrel ukuze ikhishwe ngoba isebenzisa insimbi ye-premium alloy nama-coatings athuthukile. Ngiyabona ukuthi lezi zici ziyisiza kanjani ukumelana nokushisa, ukucindezela, nokuguga. Uma kuqhathaniswa nezinketho ezijwayelekile, iprimiyamuIpayipi le-PVC i-screw barrel eyodwaihlala kuze kube izikhathi eziyisithupha ubude. Ngiphinde ngithembele ku-ai-screw barrel eyodwa yokubumbakanye aIpayipi le-PE extruder umphongolo wesikulufa esisodwangemisebenzi enzima.

Izinto kanye Nokwakhiwa Kwe-PVC Pipe Screw Barrel for Extrusion

I-Premium Alloy Steel Selection

Uma ngikhetha i-PVC Pipe screw barrel for extrusion, ngigxila ensimbi yealloy. Insimbi efanele yenza wonke umehluko ekuqineni nasekusebenzeni. Ngithembele ezintweni ezifanaI-38CrMoAlA ne-42CrMongoba bayanikelaamandla aphezulu kanye nokumelana nokugqoka okuhle kakhulu. Lezi zinsimbi zisingatha izimo ezinzima ze-extrusion, kuhlanganise nezinga lokushisa eliphezulu nokucindezela. Ngiphinde ngibheke imiphongolo enama-bimetallic liners noma insimbi engagqwali uma ngidinga ukuvikeleka okwengeziwe ekugqwaleni okuvela kumakhemikhali e-PVC e-chlorine.

Nazi ezinye zezinsimbi ze-alloy ezivame kakhulu nokusetshenziswa kwazo:

| I-alloy Steel / Material | Izimpawu Ezisemqoka | Isicelo ku-PVC Screw Barrels |

|---|---|---|

| I-AISI 4140 | Amandla amahle, ukushisa kuyalapheka, kutholakala kabanzi | Okujwayelekile emiphongolweni eminingi yesikulufu ye-PVC |

| I-AISI 4340 | Amandla aphakeme, ukungena okungcono kokwelashwa kokushisa | Isetshenziselwa izindiza ezijulile noma izikulufi ezincane zobubanzi |

| I-Nitralloy 135-M | I-Aluminium ye-nitriding, ukumelana nokugqokwa okuthuthukisiwe | Indawo ene-nitrided impilo ende |

| 17-4 PH Insimbi engagqwali | Iqinile, imelana nokugqwala | Izikulufu ezincane ezidinga ukumelana nokugqwala |

| I-D2 kanye ne-H13 Tool Steels | Ukumelana nokugqokwa okuphezulu, kuyalapheka, ukumelana nokugqwala | Izindawo zokuhuzuka okuphezulu, imikhono, izikulufu zepulasitiki |

| I-CPM Tool Steels (CPM 10V, njll.) | I-abrasion ephezulu kanye nokumelana nokugqwala | Izinhlanganisela ezigcwele, ukumelana nokugqoka okuhlala isikhathi eside |

Ngihlala ngikhetha ibanga lensimbi ngokusekelwe ezidingweni zenqubo ye-extrusion. Izinsimbi ze-alloy ezinamandla aphezulu kanye nama-alloys e-bimetallic kunginika ithemba lokuthi i-PVC Pipe screw barrel for extrusion izohlala phakathi neminyaka yokusetshenziswa kanzima.

Ukwelashwa Okuthuthukisiwe Kobuso Nokuqina

Ukwelashwa kwendawo engaphezulu kudlala indima enkulu ekutheni imiphongolo yami yesikulufu ihlala isikhathi esingakanani. Ngisebenzisa i-nitriding ukwakha ungqimba oluqinile ensimbi, olungafinyelela ku-70 HRC. Lesi singqimba simelana nokugqoka nokucindezeleka, ngisho nalapho umgqomo ubhekene nokucindezela okukhulu nokushisa. I-Chrome plating yengeza indawo ebushelelezi futhi inciphisa ukungqubuzana, okwenza ukuhlanza kube lula futhi kuthuthukise ukugeleza kwe-ncibilika. Kwesinye isikhathi, ngikhetha ama-alloys e-bimetallic noma ama-tungsten carbide ukumelana nokuhuzuka okukhulu.

Ithiphu: I-Nitriding yakha ungqimba lwe-nitride olucishe lube ngu-0.5-0.8mm ukujula, oluvikela umgqomo ekugugeni nasekugxumeni. I-Chrome Plating, ngokuvamile engu-10-50 microns ukujiya, igcina ingaphezulu ishelela futhi kusiza ukuvimbela ukwakheka kwezinto.

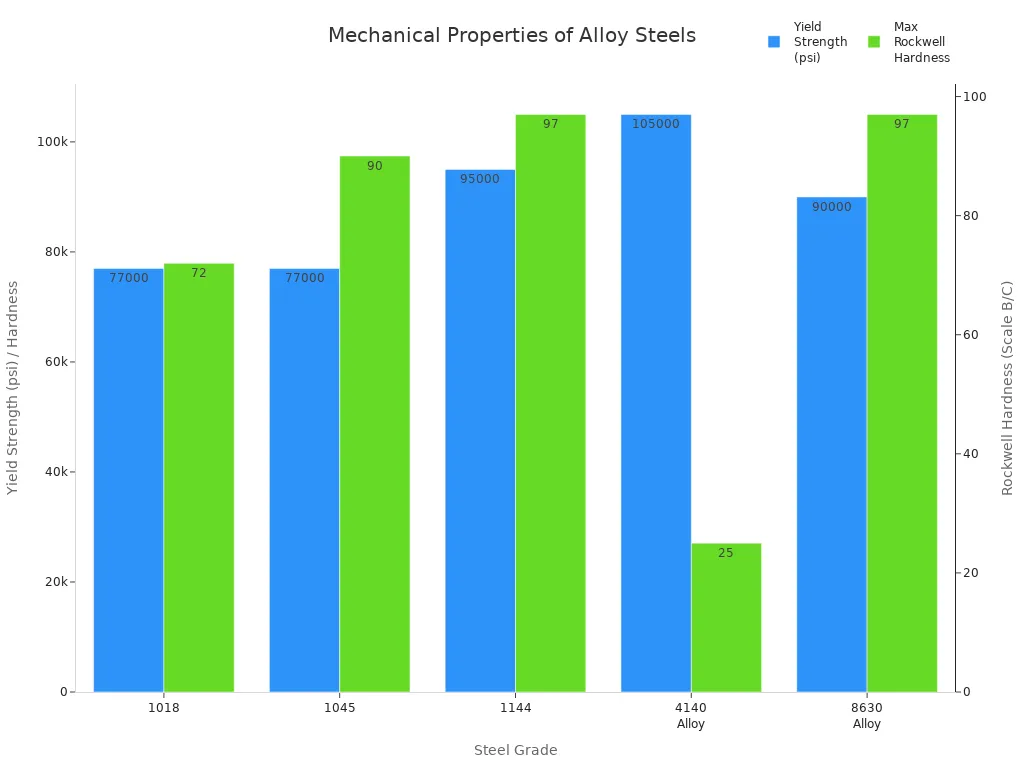

Nakhu ukubuka okusheshayo kwezakhiwo zezinsimbi engizisebenzisayo:

| Ibanga Lensimbi | Amandla Okukhiqiza (psi) | Ukuqina kwe-Max Rockwell (Isikali) | Amanothi ngezakhiwo nokusetshenziswa |

|---|---|---|---|

| 4140 ingxubevange | 60,000 - 105,000 | C20 – C25 | Iqinile, i-ductile, imelana nokugqoka |

| 17-4 PH Ingenasici | 110,000 | C40 | Iqinile, imelana nokugqwala |

| I-D2 Tool Steel | 90,000 | C55 | Ukumelana nokugqokwa okuphezulu, ukumelana nokugqwala |

Ngihlale ngifanisa ukwelashwa okungaphezulu nohlobo lwepulasitiki nezithasiselo engizisebenzisayo. Ngale ndlela, umphongolo wami we-PVC Pipe screw for extrusion uhlala uthembekile futhi usebenza kahle.

Ukukhiqiza Okunembayo kanye Nobuqotho Besakhiwo

Ukukhiqiza okunembayo kuwumgogodla we-screw barrel eqinile. Ngiyethemba ukwenza imishini ye-CNC kuzogcina ukubekezelelana kuqinile, kwesinye isikhathi kunembile njengo-±0.01 mm. Lokhu kunemba kuqinisekisa ukuthi i-screw kanye ne-barrel mesh ngokuphelele, okubalulekile ekudluliseni okuphumelelayo kwe-PVC nokuxutshwa. Nginaka kakhulu i-screw geometry—izindiza, ukujula kwesiteshi, iphimbo, nesilinganiso sokucindezela. Lezi zici zingisiza ukuba ngilawule ingcindezi nezinga lokushisa, ngigweme ukuwohloka kwezinto.

- Ngisebenzisa izingxenye ze-vacuum vent kanye nezinto zokuxuba ukuze ngisuse amagesi avaleleke futhi ngihlanganise izithasiselo kahle.

- Izinto zokushisisa namashaneli okupholisa emgqonyeni ngivumele ngilawule izindawo zokushisa, ngigcine ukuncibilika kuzinzile.

- Amasistimu okulawula ahlanganisiwe angivumela ukuthi ngiqaphe futhi ngilungise inqubo ngesikhathi sangempela, ngigcine ukunemba kobukhulu futhi ngivimbele amaphutha.

Uma ngibona noma yikuphi ukuguga noma ukuchezuka kobukhulu, ngithatha isinyathelo ngokushesha. Ngisho nezinguquko ezincane zinganciphisa umthamo wokudlulisa kanye nokusebenza kahle kwe-plasticizing, okuholela ezindongeni zamapayipi ezingalingani noma izinhlayiya ezingancibilikisiwe. Ngokugcina ukunemba, ngiqinisekisa ukuthi umphongolo wami wesikulufa we-PVC Pipe we-extrusion uletha ikhwalithi engaguquki kanye nempilo ende yesevisi.

Izinzuzo Zokuklama Nezokusebenza ze-PVC Pipe Screw Barrel for Extrusion

I-Optimized Screw Geometry kanye Nokudla Okufanayo

Uma ngikhetha i-PVC Pipe screw barrel for extrusion, nginaka kakhulu i-screw geometry. Idizayini efanele ingisiza ukuba ngifinyelele ukuphakelwa okubushelelezi nokufanayo kwempahla ye-PVC. Ngibheka izici ezisekela ezokuthutha nokuxuba. Nazi ezinye zezakhi eziyinhloko engizicabangelayo:

- Izindiza ezijulile namashaneli esigabeni sokudlulisa zihambisa impahla ngokushesha ngaphandle kokugunda kakhulu.

- Ukujula kwesiteshi kuncipha ukusuka endaweni yokudlulisa kuya endaweni yemitha, okulinganisa ukuncibilika nokuxutshwa.

- Ukuphakama kwendiza okukhudlwana kuhambisa izinto eziningi ngamandla amancane, kuyilapho ama-elementi ahlehlayo asiza ukulawula ukugeleza nokuthuthukisa ukuhlanganisa.

- Isigaba sokuphakelayo sigcina impahla igeleza futhi ivimbela ukuvinjwa.

- Isigaba sokucindezelwa siyancibilika futhi sixube i-PVC, kusetshenziswa ukushisa okuvela ekungqubuzaneni.

- Ingxenye yokulinganisa iqinisekisa ukukhishwa okuqhubekayo kwezinto ezincibilikisiwe.

Ngihlale ngiqinisekisa ukuthi i-screw geometry ifana nezakhiwo ze-PVC kanye nezidingo zenqubo ye-extrusion. Le dizayini ecophelelayo ingisiza ngigweme amaphutha futhi igcine ukugeleza kokubalulekile kuzinzile.

Uma ngibona ukuguga kwesikulufu, ngithatha isinyathelo ngokushesha. Ngisho nezinguquko ezincane ku-geometry zingabangela ukugeleza okungalingani kanye namaphutha epayipi lokugcina. Ngokugcina isikulufu sisesimweni esiphezulu, ngigcina i-extrusion yekhwalithi ephezulu futhi nginciphisa imfucuza.

Amasistimu Okushisisa Nokupholisa Ahlanganisiwe

Ukulawula izinga lokushisa okunembile kubalulekile ukuze kukhiqizwe amapayipi e-PVC aqinile futhi angaguquki. Ngithembele ezinhlelweni zokushisisa ezithuthukisiwe nezokupholisa ezakhelwe emgqonyeni wesikulufu. Lawa masistimu angisiza ukuthi ngigcine izinga lokushisa lilungile phakathi nesigaba ngasinye sokukhipha.

| Uhlobo Lwesistimu | Incazelo | Umongo Wohlelo Lokusebenza |

|---|---|---|

| Isistimu Yokushisa | Izindlela zokushisisa ngogesi, njengokungeniswa nokushisa kokumelana, zifakwa ngaphandle komgqomo | Inikeza ukushisa okudingekayo ukuze kuncibilike i-PVC |

| Uhlelo Lokupholisa | Amasistimu okupholisa amanzi noma umoya; ukupholisa umoya kuma-extruder amancane, amanzi amakhulu | Ivimbela ukushisa ngokweqile futhi igcina izinga lokushisa lizinzile |

Ngisebenzisa izinzwa zokushisa ukuze ngiqaphe inqubo ngesikhathi sangempela. Izilawuli ezizenzakalelayo zilungisa ukushisisa nokupholisa njengoba kudingeka. Lokhu kusetha kugcina izinga lokushisa elincibilikayo lizinzile, okubalulekile kwikhwalithi yamapayipi nokunemba kobukhulu.

- Ukulawula izinga lokushisa endaweni ngayinye kuqinisekisa ukuthi i-PVC incibilika ngokuphelele futhi ngokulinganayo.

- Izinga lokushisa elifanele le-die livimbela ipayipi ekuncipheni noma ukuqina ngokushesha.

- Izinhlelo zokupholisa zisiza ipayipi ukuthi igcine isimo sayo futhi inciphise ukucindezeleka kwangaphakathi.

Ngalawa masistimu, ngingakwazi ukulungisa ngokushesha izinguquko futhi ngigweme amaphutha njengezindonga ezingalingani noma izindawo ezimaholoholo.

Ukumelana Nokugqoka, Ukugqwala, kanye Nokucindezela Okuphezulu

I-PVC Pipe screw barrel for extrusion ibhekene nezimo ezinzima. Ngikhetha imiphongolo eyenziwe ngama-alloys akhethekile kanye nezingubo ezithuthukisiwe ukumelana nokuguga nokugqwala. Ukucubungula kwe-PVC kungakhulula i-hydrochloric acid, ehlasela insimbi evamile. Ukuvimbela lokhu, ngisebenzisa imiphongolo ye-bimetallic enamalayini acebile nge-nickel kanye nezingubo eziqinile njenge-tungsten carbide.

- Ukunamathela okunamathelayo kwenzeka lapho izingxenye zensimbi zihlikihla ndawonye.

- Ukugqokwa kwe-abrasive kuvela kumafayili afana namafayibha engilazi noma amaminerali ku-PVC.

- Ukuguga okubolayo kubangelwa amakhemikhali akhululwa ngesikhathi sokucubungula.

Ngiphinde ngiqinisekise ukuthi isikulufu kanye nezinto zomgqomo ziyahambelana. Lokhu kuvimbela izinkinga emazingeni ahlukene okunwetshwa lapho kushisa. Ukuhlola njalo nokunakekela kungisiza ukuthi ngibone ukuguga kusenesikhathi futhi ngigweme ukulungisa izinto ezinkulu.

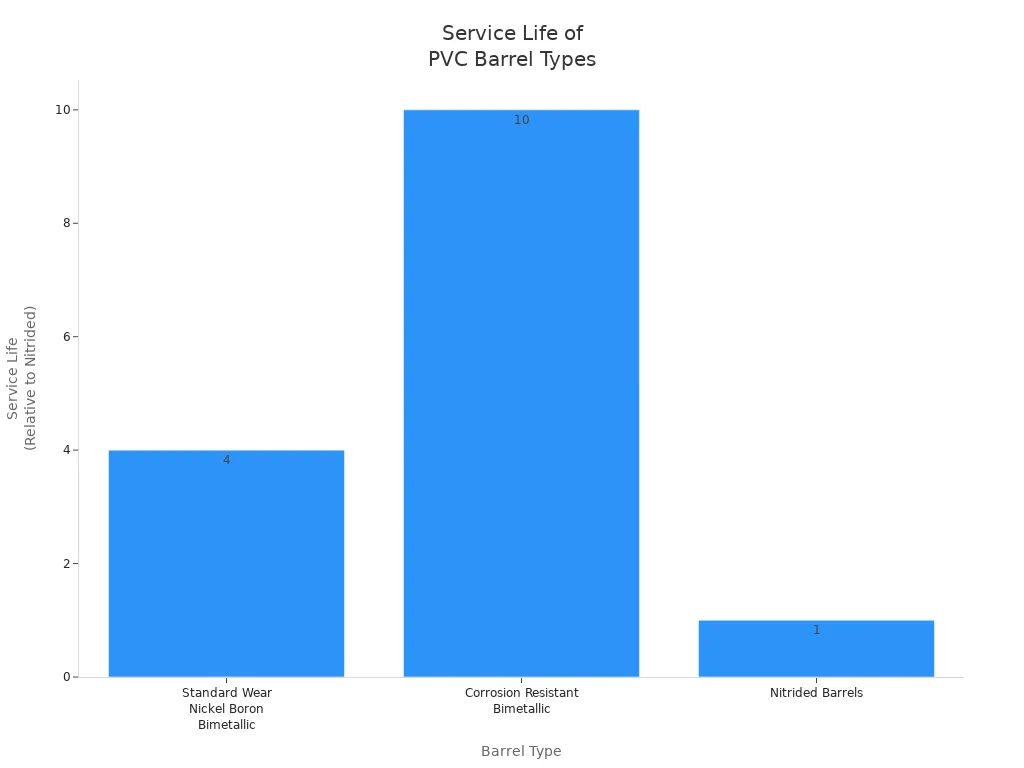

| Uhlobo Lomgqomo | Gqoka Ukumelana | Ukumelana Nokugqwala | Impilo Yesevisi Iqhathaniswa Nemigqomo Ye-Nitrided |

|---|---|---|---|

| I-Standard Wear Nickel Boron Bimetallic | Ukumelana okuhle kakhulu kwe-abrasion | Ukumelana nokugqwala okumaphakathi | Okungenani izikhathi ezi-4 ubude |

| I-Bimetallic Engavimbeli Ukugqwala | Ukumelana nokugqoka okuhle kakhulu | Kuhle kakhulu ngokumelene ne-HCl nama-acids | Izikhathi ezingaphezu kuka-10 ubude emkhathini odlayo |

| I-Nitrided Barrels | Ukuqina kwendawo ephezulu | Ukumelana nokugqwala okungekuhle | Isisekelo (1x) |

Ngokusebenzisa lezi zinto kanye nemiklamo, ngelula impilo yezinto zokusebenza zami futhi ngigcina ukukhiqiza kusebenza kahle, ngisho nangaphansi kwengcindezi ephezulu kanye nezinto ezihugayo.

Ikhwalithi Yokunweba Engaguquguquki kanye Nempilo Yesevisi Enwetshiwe

Ngiyazi ukuthi ikhwalithi engaguquki ibalulekile ekukhiqizeni amapayipi e-PVC. Ngiqapha amapharamitha abalulekile afana nezinga lokushisa, ingcindezi, nesivinini ukuze ngigcine inqubo izinzile. Ngisebenzisa amathuluzi anembayo ukuhlola ubukhulu bepayipi futhi ngibheke ukonakala kwendawo. Amasistimu azenzakalelayo angisiza ukuba ngibambe izinkinga kusenesikhathi futhi ngigcine inqubo isendleleni.

- Ngilandelela umthamo wokukhiphayo, izilinganiso zokukhubazeka, nokusetshenziswa kwamandla ukuze ngilinganisele ukusebenza.

- Ukugcinwa okuvamile nokuhlolwa kokuqondanisa kungisiza ngigweme isikhathi sokuphumula.

- Imiphongolo yesikulufu eqinile enezingubo ze-bimetallic inciphisa ukuthi ngidinga ukumisa kaningi kangakanani ukuze ngilungiswe.

Uma ngitshala imali emgqonyeni wesikulufu wekhwalithi ephezulu we-PVC ukuze ngikhiphe, ngibona ukuphuka okumbalwa kanye nokumosha okuncane. Izindleko zami zokunakekela ziyehla, futhi ngingakwazi ukucubungula izinto ezigaywe kabusha kalula. Ngiphinde ngibone ukusetshenziswa kwamandla okuphansi ngoba imishini isebenza kahle kakhulu.

Ngokwazi kwami, lezi zinzuzo zengeza ekongeni kwezindleko ezibalulekile kanye nokukhiqiza okuphezulu. Ngingakwazi ukuhlangabezana nezinsuku zokugcina zokulethwa futhi ngigcine amakhasimende ami ejabule.

Ngitshala ku-PVC Pipe screw barrel ukuze ngikhiphe ngoba iletha ukusebenza okuhlala isikhathi eside kanye nekhwalithi yepayipi engaguquki.

- Imiklamo ye-modular imigqomo nezinto ezithuthukisiwe zinciphisa isikhathi sokuphumula kanye nezindleko zokuyilungisa.

- Ukuhlola okuvamile kanye nama-coatings afanelekile kuyangisiza ukuthi ngihlangabezane nezindinganiso zomkhakha.

| Zuza | Umphumela |

|---|---|

| Ukuqina okuphezulu | Izindleko zokusebenza eziphansi |

| Ubuchwepheshe obuphambili | Ukwaneliseka kwamakhasimende okuthuthukisiwe |

FAQ

Ngiwugcina kanjani umphongolo wami wesikulufa we-PVC Pipe ukuze ukhishwe?

Ngihlanza umgqomo njalo. Ngihlola ukuguga nokugqwala. Ngishintsha izingxenye ezigugile ngokushesha. Ngisebenzisa izithambisi ezinconyiwe futhi ngiqaphe izilungiselelo zokushisa.

Ithiphu: Hlela ukuhlolwa kwanyanga zonke ukuze uthole izimpawu zokuqala zokuguga.

Yikuphi ukwelashwa okungaphezulu okusebenza kahle kakhulu ku-PVC extrusion ephezulu yokuhuzuka?

Ngincamela i-nitriding yemisebenzi eminingi. Ngisebenzisa i-bimetallic noma i-tungsten carbide coatings lapho ngicubungula amakhompawundi abrasive. Lezi zindlela zokwelapha zinweba impilo yesevisi futhi zimelane nokuguga.

Ngingakwazi ukwenza ngendlela oyifisayo ijiyomethri yesikulufu ngosayizi abahlukene bepayipi le-PVC?

Ngisebenza nabakhiqizi ukulungisaisikulufu ububanzi, iphimbo, nokujula kwendiza. Ijiyomethri yangokwezifiso ingisiza ngifinyelele ukugeleza kokuncibilika okuphelele kanye nekhwalithi yepayipi engaguquki yanoma yimuphi usayizi.

| Inketho yokwenza ngokwezifiso | Zuza |

|---|---|

| Ububanzi | Ifanisa ukujiya kwamapayipi |

| Iphimbo | Ilawula ukuhamba kwezinto |

| Ukujula Kwendiza | Ithuthukisa ikhwalithi yokuxuba |

Isikhathi sokuthumela: Aug-27-2025