Ukubumba umjovo we-screw kusebenzisa isikulufu esijikelezayo ukuze kuncibilike futhi kuxube ipulasitiki ngaphambi komjovo. Ukubumba komjovo we-plunger kuncike ku-plunger ephusha ipulasitiki encibilikisiwe iqonde ngqo esikhunjeni. Amafekthri avame ukukhetha umphongolo wesikulufu wePlastiki Umjovo wokubumba ukuze kuhlanganiswe izinto ezingcono. Abanye basebenzisa aI-Twin Plastic Screw Barrelnoma aI-Blowing Screw Barrel. Amafekthri Emigqomo Yesikulufu Eyodwa Yepulasitikigxila ekunembeni nokuvumelana.

Uhlolojikelele Lokubumba Lomjovo Wokujova

Isebenza kanjani i-Screw Injection Molding

Ukubumba umjovo wesikulufuisebenzisa isikulufu esizungezayo ngaphakathi kombhobho oshisayo. Isikulufu sidonsa ama-pellets epulasitiki ku-hopper bese siwayisa phambili. Njengoba isikulufu siphenduka, sincibilikisa ipulasitiki ngokungqubuzana nokushisa. Ipulasitiki encibilikisiwe iqoqa ngaphambi komgqomo. Uma izinto ezanele zibuthana, isikulufu siphushela ipulasitiki encibilikisiwe esikhunjeni. Le nqubo iqinisekisa ngisho nokuncibilika nokuxuba. I-Plastic Injection molding screw barrel idlala indima ebalulekile kulolu hlelo ngokunikeza ukulawula okunembayo phezu kwezinga lokushisa nokucindezela.

Izici Eziyinhloko Nezinzuzo

Ukubumba umjovo wesikulufa kunikeza izinzuzo ezimbalwa:

- Ukuxuba nokuncibilika kwempahla engaguquki

- Isivinini esikhulu sokukhiqiza nokusebenza kahle

- Ikhono lokuphatha amapulasitiki amaningi

- Ukulawula okunembile phezu kosayizi wokudutshulwa nokucindezela komjovo

Qaphela: Amafekthri avame ukukhetha le ndlela yokwethembeka kanye nekhono lokukhiqiza izingxenye eziyinkimbinkimbi ezinokubekezelelana okuqinile.

Izicelo Ezivamile

Abakhiqizi basebenzisa i-screw injection molding ezimbonini eziningi. Eminye imikhiqizo evamile ihlanganisa:

- Izingxenye zezimoto

- Izindlu zama-electronics zabathengi

- Izingxenye zedivayisi yezokwelapha

- Iziqukathi zokupakisha

Le ndlela isekela kokubili ukukhiqizwa kwevolumu ephezulu kanye nemiklamo yengxenye enemininingwane.

I-Plastic Injection Molding Screw Barrel

Iqhaza Enqubweni Yokujova

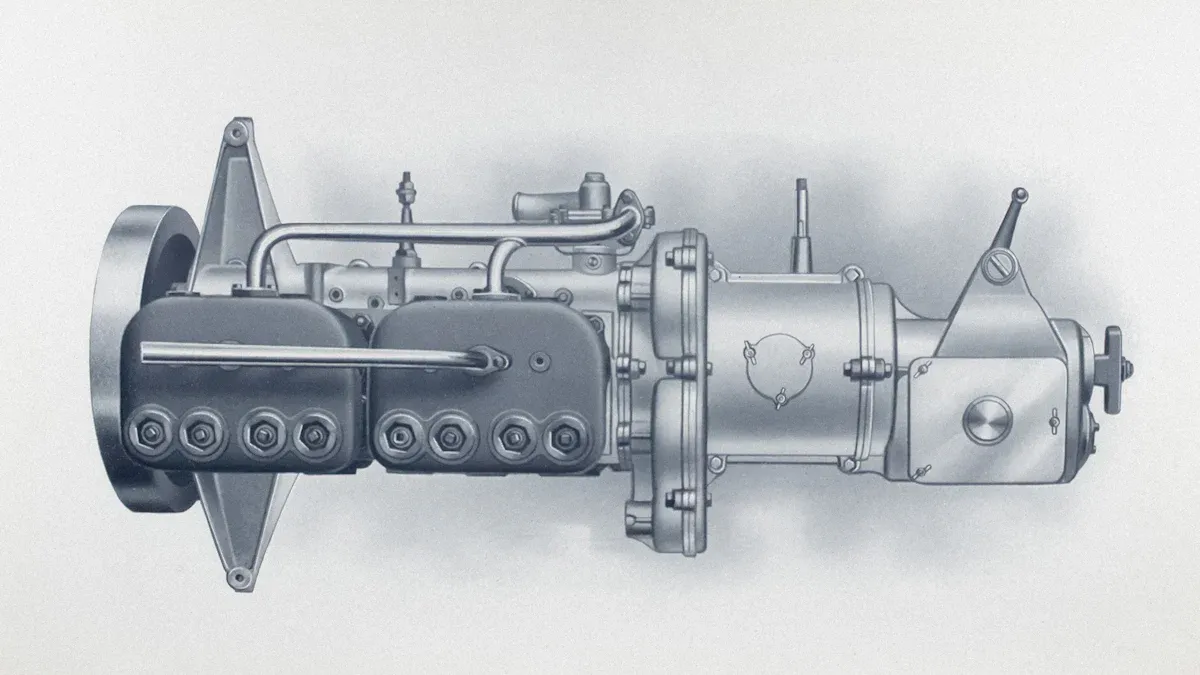

II-Plastic Injection molding screw barrelidlala indima ebalulekile enqubweni yokubumba umjovo. Iphethe isikulufu esizungezayo esiyisa ama-pellets epulasitiki phambili. Njengoba isikulufu siphenduka, sidala ukungqubuzana nokushisa. Lesi senzo sincibilikisa ipulasitiki ngokulinganayo. Isikulufu sibe sesiphusha ipulasitiki encibilikisiwe ibheke ngaphambili komgqomo. Uma kuqoqwa impahla eyanele, isikulufu siyayijova esikhunjeni. Le nqubo iqinisekisa ukuthi ipulasitiki ifinyelela izinga lokushisa elifanele kanye nokuvumelana.

I-Plastic Injection molding screw barrel isiza ukulawula isivinini nengcindezi yomjovo. Lokhu kulawula kuvumela amafekthri ukuthi akhiqize izingxenye ngokunemba okuphezulu nokuphindaphinda.

Ukucatshangelwa Kokuklama Nokukhiqiza

Onjiniyelaklama umphongolo wesikulufa wePlastiki Umjovo wokubumbaukuphatha izinhlobo ezahlukene zamapulasitiki. Bakhetha izinto ezimelana nokuguga nokugqwala. Umgqomo kumele umelane namazinga okushisa aphezulu kanye nezingcindezi. Ukwenziwa kwemishini eqondile kuqinisekisa ukuthi ingaphakathi lomgqomo libushelelezi. Le ndawo ebushelelezi isiza isikulufu ukuhambisa ipulasitiki ngaphandle kokunamathela.

Abakhiqizi basebenzisa okokusebenza okuthuthukile ukukhiqiza umgqomo wesikulufu wePlastiki Umjovo wokubumba. Bavame ukusebenzisa imishini ye-CNC nezithando zokushisa ukushisa. Lezi zinyathelo zithuthukisa amandla nokuqina komgqomo. Ukuhlola ngokucophelela kuhlola ukuthi umphongolo ngamunye uhlangabezana nezindinganiso eziqinile zekhwalithi.

- Izici eziyinhloko zedizayini zifaka:

- Ubude nobubanzi bomgqomo

- Uhlobo lwensimbi noma i-alloy esetshenzisiwe

- Izindlela zokwelapha ezingaphezulu

Umphongolo oklanywe kahle we-Plastic Injection molding screw usekela ukukhiqizwa okuphumelelayo nempilo ende yesevisi.

I-Plunger Injection Molding Uhlolojikelele

Indlela I-Plunger Injection Molding Esebenza Ngayo

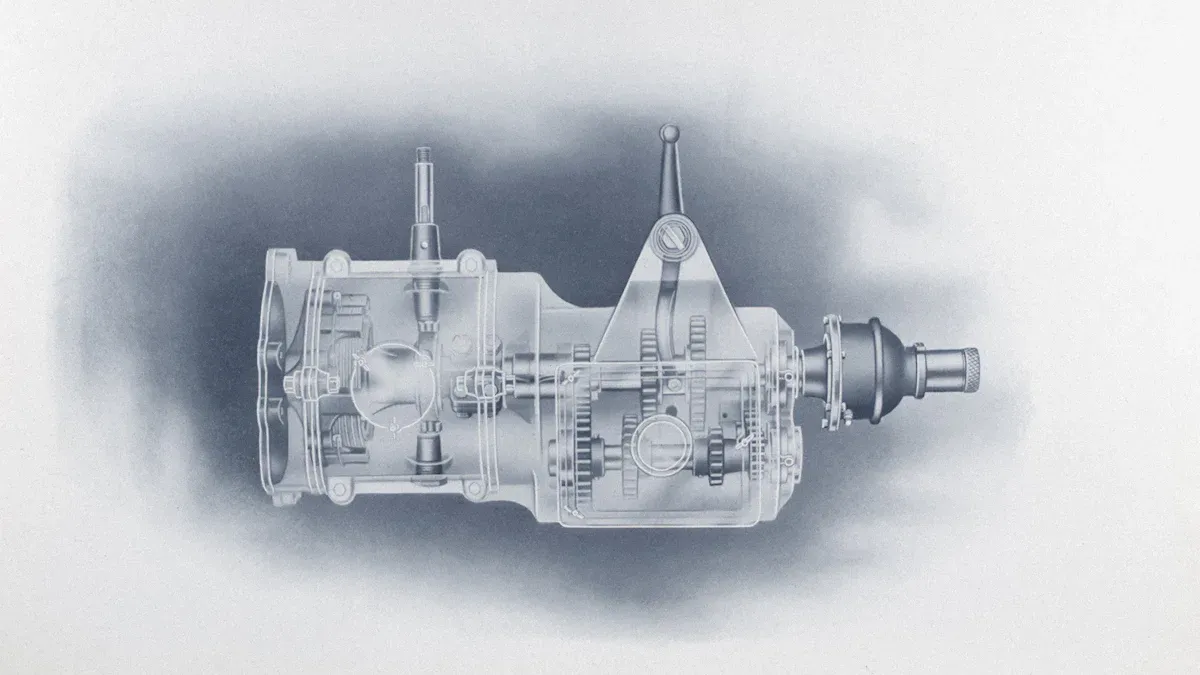

Ukubumba umjovo we-plunger kusebenzisa indlela elula. Umgqomo oshisayo ubamba izinto zepulasitiki. Iumshiniishisa ipulasitiki ize ithambe futhi ilungele ukubunjwa. I-plunger, ebukeka njengepiston, iphushela ipulasitiki encibilikisiwe phambili. I-plunger iphoqa ipulasitiki ukuthi ingene emgodini wesikhunta. Isikhunta sibumba ipulasitiki ibe umkhiqizo wokugcina. Inqubo ayihlanganisi ipulasitiki njengoba kwenza uhlelo lwesikulufu. I-plunger ihamba ngomugqa oqondile futhi icindezela ngokuqondile.

Qaphela: Ukubumba komjovo we-plunger kusebenza kangcono kumajamo ayisisekelo nezingxenye ezingaxakile kangako.

Izici Eziyinhloko Nezinzuzo

Ukubumba komjovo we-plunger kunikeza izici ezimbalwa ezihlukile:

- Umklamo womshini olula

- Izindleko zemishini yokuqala ephansi

- Ukusebenza okulula nokugcinwa

- Ifanele ukugijima kokukhiqiza okuncane

Le ndlela inikeza ukukhetha okuhle kwezimboni ezidinga ukukhiqiza izingxenye zepulasitiki ezilula. Inqubo isebenzisa izingxenye ezimbalwa ezihambayo, ezinganciphisa izidingo zokunakekelwa. Ama-opharetha angamisa futhi aqhube umshini ngokuqeqeshwa okuyisisekelo.

Izicelo Ezivamile

Izimboni zisebenzisa ukubumba komjovo we-plunger emikhiqizweni ethile. Ezinye izibonelo ezivamile zihlanganisa:

- Amakhava okushintsha kagesi

- Amathoyizi epulasitiki alula

- Izinto zasendlini eziyisisekelo

- Izingxenye zezimoto ezincane

Le ndlela ifanelana kangcono nezinto ezingadingi ukunemba okuphezulu noma izimo eziyinkimbinkimbi. Abakhiqizi abaningi bakhetha ukubumba komjovo we-plunger kuma-run okukhiqiza amafushane noma lapho besebenza ngezinto eziyisisekelo zepulasitiki.

Ukuqhathanisa Okuqondile Kwe-Screw kanye Ne-Plunger Injection Molding

Umehluko Wenqubo

Ukubumba umjovo wesikulufu kanye ne-plunger kusebenzisa izindlela ezihlukene ukwenza izingxenye zepulasitiki. Ukubumba umjovo wesikulufa kusebenzisa aisikulufu esijikelezayoukuncibilika, ukuxuba, nokuphusha ipulasitiki esibunjeni. Isikulufu siyisa impahla phambili ngenkathi siyishisa futhi siyihlanganisa. Le nqubo idala ukuncibilika okufanayo kanye nekhwalithi engaguquki.

Ukubumba umjovo we-plunger kusebenzisa i-plunger ehambayo. I-plunger iphushela ipulasitiki eseyincibilikile kakade esikhunjeni. Inqubo ayihlanganisi ukwaziswa okuningi. I-plunger ihamba ngendlela eyodwa futhi icindezela ngokuqondile.

Ithiphu: Izimboni zivame ukukhetha ukubumba komjovo ngezikulufu zezingxenye eziyinkimbinkimbi ngoba zixuba futhi zincibilikise ipulasitiki ngokulinganayo.

Umehluko Wokusebenza

Ukusebenza kuyehluka phakathi kwalezi zindlela ezimbili. Ukubumba umjovo wesikulufa kunikeza ukunemba okuphezulu nokuphindaphindeka. Isikulufu silawula inani lepulasitiki kanye nesivinini somjovo. Lokhu kulawula kusiza amafekthri enze izingxenye ezinokubekezelelana okuqinile kanye nezindawo ezibushelelezi.

Ukubumba komjovo we-plunger kusebenza kangcono kumajamo alula. Inqubo ayinikezi izinga elifanayo lokulawula. Izingxenye zingabonisa ukuhluka okwengeziwe ngosayizi kanye nesiphetho. Amasistimu wama-plunger ngokuvamile asebenza ngesivinini esincane futhi angase angakwazi ukuphatha imiklamo enemininingwane.

- Ukubumba umjovo wesikulufu:

- Ukunemba okuphezulu

- Izikhathi zomjikelezo osheshayo

- Imiphumela engaguquki

- Ukubumba umjovo we-plunger:

- Ukunemba okuyisisekelo

- Imijikelezo enensayo

- Kuhle kakhulu ezingxenyeni ezilula

Umehluko Wokusingatha Izinto

Ukuphatha impahla kudlala indima ebalulekile kuzo zombili izindlela. I-screw injection molding iphatha izinhlobonhlobo zamapulasitiki. Isikulufu sihlanganisa ama-colorants nezithasiselo kupulasitiki. Lokhu kuhlanganisa kuqinisekisa ngisho umbala kanye nezakhiwo kuyo yonke ingxenye.

Ukubumba komjovo we-plunger akuhlanganisi izinto ngokuphelele. I-plunger iphusha ipulasitiki phambili ngaphandle kokuyihlanganisa. Le ndlela isebenza kangcono ngezinto eziyisisekelo kanye nemibala eyodwa.

| Isici | Isikulufu Umjovo Molding | I-Plunger Injection Molding |

|---|---|---|

| Ukuxuba Material | Kuhle kakhulu | Inomkhawulo |

| Ukusabalalisa Okungeziwe | Umfaniswano | Akulingani |

| Ukungaguquguquki Kombala | Phezulu | Kuphakathi |

Izindleko Nomehluko Wokulungisa

Izindleko nokunakekelwa nakho kuyahluka phakathi kwalezi zindlela ezimbili. Imishini yokubumba i-screw injection ngokuvamile ibiza kakhulu ukuyithenga. Basebenzisa izingxenye ezithuthukile futhi badinga opharetha abanekhono. Nokho, zikhiqiza izingxenye ngokushesha futhi ngokumosha okuncane. Ukunakekela kungase kuhileleukuhlola isikulufu nomgqomookokugqoka.

Imishini yokubumba umjovo we-plunger ibiza kancane ukuyithenga. Umklamo ulula futhi kulula ukuwugcina. Abasebenzisi bangafunda ukusebenzisa imishini ngokushesha. Ukunakekela ngokuvamile kuhilela izinyathelo ezimbalwa, njengokuhlola i-plunger nama-seal.

Qaphela: Izimboni kufanele zicabangele kokubili ukutshalwa kwezimali kokuqala kanye nezindleko zokusebenza zesikhathi eside lapho kukhethwa indlela.

Ithebula lezinzuzo nezingozi

Ukukhetha indlela efanele yokubumba umjovo kuncike ekuqondeni amandla kanye nobuthakathaka benqubo ngayinye. Ithebula elingezansi ligqamisa okuhle nokubi okuyinhloko kwe-screw kanyeukubumba umjovo we-plunger. Lokhu kuqhathanisa kusiza abakhiqizi ukuthi benze izinqumo ezinolwazi ngezidingo zabo zokukhiqiza.

| Isici | Isikulufu Umjovo Molding | I-Plunger Injection Molding |

|---|---|---|

| Izinzuzo | - Excellent impahla ukuxuba - Isivinini sokukhiqiza esiphezulu - Ukulawula ukudubula okunembile - Iphatha izingxenye eziyinkimbinkimbi - Ikhwalithi engaguquki | - Umklamo womshini olula - Izindleko zokuqala eziphansi - Easy ukusebenza - Ifanele imigijimo emincane - Izingxenye ezihambayo ezimbalwa |

| Ububi | - Ukutshalwa kwezimali kokuqala okuphezulu - Idinga opharetha abanamakhono - Ukunakekela okuyinkimbinkimbi | - Ukuxuba izinto ezilinganiselwe - Ukunemba okuphansi - Izikhathi zomjikelezo ezihamba kancane - Kuhle kakhulu kumajamo ayisisekelo |

Ithiphu: Ukubumba komjovo wesikulufa kufanelana nokukhiqizwa kwevolumu ephezulu kanye nezingxenye ezinemininingwane. Ukubumba komjovo we-plunger kufanela imikhiqizo elula nokugijima okufushane.

Abakhiqizi bavame ukukhetha ukubumba komjovo wesikulufa ngekhono layo lokukhiqiza izingxenye ezisezingeni eliphezulu, eziyinkimbinkimbi ngesivinini nokuvumelana. Ukubumba umjovo we-plunger kuhlala kuwukukhetha okusebenzayo kwezinto eziyisisekelo nalapho ibhajethi noma ubulula bubaluleke kakhulu. Indlela ngayinye inikeza izinzuzo eziyingqayizivele, ngakho ukuhlola ngokucophelela kuqinisekisa ukulingana okungcono kakhulu kwemigomo ethile yokukhiqiza.

Ukukhetha Indlela Elungile Yokubumba Umjovo

Ukukhetha indlela engcono kakhulu yokubumba umjovo kuncike ezintweni ezimbalwa ezibalulekile. Imboni ngayinye kufanele icabangele izidingo zayo eziyingqayizivele zokukhiqiza ngaphambi kokwenza isinqumo. Idizayini yomkhiqizo, uhlobo lwezinto ezibonakalayo, nevolumu yokukhiqiza konke kudlala indima kulokhu kukhetha.

- Ubunkimbinkimbi bomkhiqizo:

Ukubumba umjovo wesikulufuisebenza kahle ezingxenyeni ezinokwakheka okuningiliziwe noma ukubekezelelana okuqinile. Ukubumba komjovo we-plunger kufanela imiklamo elula. - Ivolumu Yokukhiqiza:

Izinzuzo zokukhiqiza zevolumu ephezulu ngokubumba umjovo wesikulufa. Le ndlela inikeza isivinini nokuvumelana. Ukubumba komjovo we-plunger kufanela amaqoqo amancane noma ama-prototypes. - Izidingo Zento:

Amanye amapulasitiki adinga ukuxubana okuphelele ukuze kube nombala noma izithasiselo.Isistimu yesikulufuinikeza ukuxubana okungcono. Isistimu ye-plunger iphatha izinto eziyisisekelo. - Isabelomali Nokunakekela:

Izimboni ezinesabelomali esilinganiselwe zingakhetha ukubumba komjovo we-plunger. Le ndlela inezindleko eziphansi zokuqala. Ukubumba umjovo we-screw kudinga ukutshalwa kwezimali okuphezulu kodwa kuletha ukusebenza kahle kwesikhathi eside.

Ithiphu: Hlala uqondanisa indlela yokubumba nezimfuneko zomkhiqizo kanye nemigomo yefekthri.

Ithebula elingezansi lifingqa izinto ezibalulekile:

| Isici | Isikulufu Umjovo Molding | I-Plunger Injection Molding |

|---|---|---|

| Izingxenye Eziyinkimbinkimbi | ✅ | ❌ |

| Ivolumu ephezulu | ✅ | ❌ |

| Ukuxuba Material | ✅ | ❌ |

| Izindleko Zokuqala Eziphansi | ❌ | ✅ |

Ukuhlola ngokucophelela kuqinisekisa ukukhetha okulungile. Indlela efanele iholela emikhiqizweni engcono kanye nokukhiqizwa okuphumelelayo.

Ukubumba komjovo we-Screw kanye ne-plunger kunikeza izinzuzo ezihlukile zamaphrojekthi ahlukene. Ukukhetha indlela efanele kuncike ezintweni eziningana:

- Buyekeza izidingo zevolumu yokukhiqiza.

- Hlola ukucaciswa kwezinto ezibonakalayo.

- Hlola ingxenye eyinkimbinkimbi.

- Hlola amakhono omhlinzeki.

- Hlaziya izici zezindleko.

Ukuhlola ngokucophelela kuqinisekisa imiphumela engcono kakhulu yawo wonke umgomo wokukhiqiza.

FAQ

Iyiphi inzuzo enkulu yokubumba umjovo wesikulufa?

Ukubumba umjovo wesikulufuinikeza ukuxubana kwempahla okuhle kakhulu. Le ndlela idala izingxenye ezingaguquki ngokunemba okuphezulu. Izimboni zivame ukuyikhethela izimo eziyinkimbinkimbi kanye nokugijima kokukhiqiza okukhulu.

Ingabe ukubumba komjovo we-plunger kungaphatha amapulasitiki anemibala?

Ukubumba umjovo we-plungerangasebenzisa amapulasitiki anemibala. Kodwa-ke, ayihlanganisi ama-colorants ngokulinganayo njengama-screw systems. Ukusatshalaliswa kombala kungase kubonakale kumfaniswano omncane ezingxenyeni eziqediwe.

Ifekthri ikhetha kanjani phakathi kokubumba umjovo wesikulufa kanye ne-plunger?

Imboni ibuyekeza ubunkimbinkimbi bomkhiqizo, umthamo wokukhiqiza, nezidingo zezinto ezibonakalayo. Amasistimu e-screw ahambisana nomsebenzi onemininingwane, wevolumu ephezulu. Imishini yama-plunger ilingana nokuma okulula namaqoqo amancane.

Isikhathi sokuthumela: Jul-16-2025