Ipayipi le-PVC lomphongolo wesikulufa esisodwa lidlala indima ebalulekile enqubweni ye-plastic extrusion, lincibilika kahle futhi lilolonge impahla ye-PVC ibe amapayipi aqinile, ahlala isikhathi eside. Ngo-2022, ama-screw extruder oyedwa ayebusa imakethe, anikela ku-63.2% wesabelo semali engenayo emhlabeni wonke, okubonisa ukwethembeka nokusetshenziswa kwawo okubanzi.Izimboni ze-Pvc pipe single screw barrelfuthiamafekthri e-plastic screw barrel eyodwasebenza ngokukhethekile ekwenzeni lezi zingxenye ngokunemba, ukuqinisekisa ukusebenza okungaguquki kanye nekhwalithi ephezulu.

Izici Eziyinhloko ze-PVC Pipe Single Screw Barrels

Izingxenye kanye Nomklamo

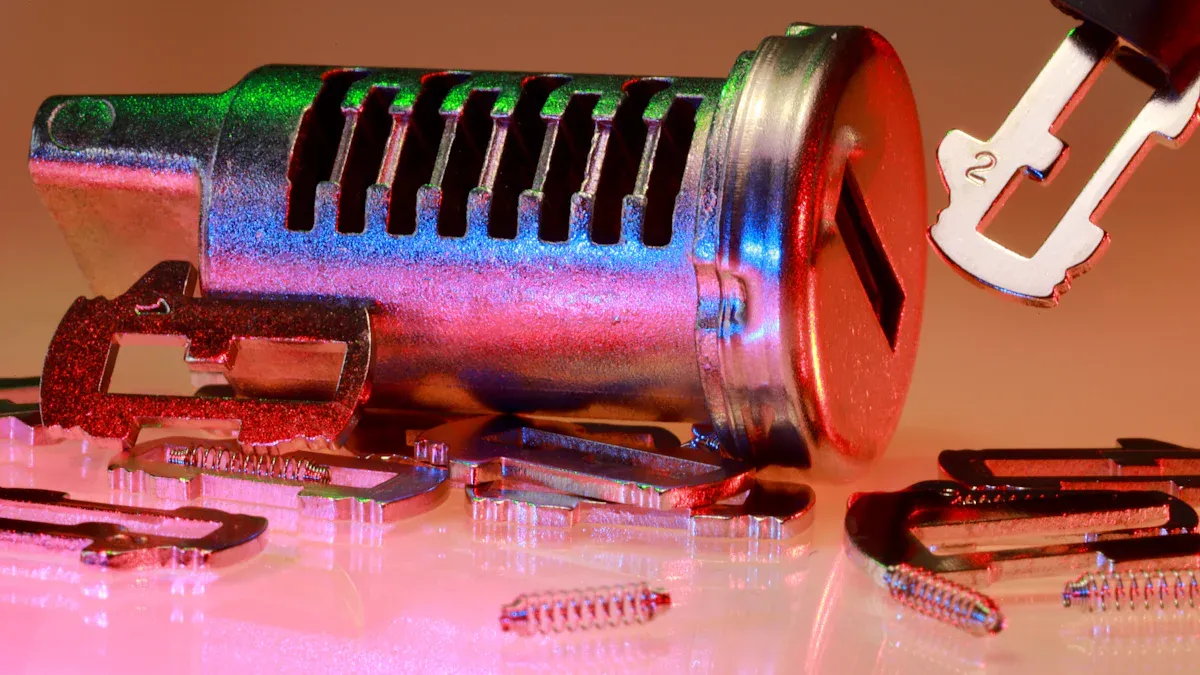

Ukwakhiwa kwepayipi le-PVCumphongolo wesikulufa esisodwaiyasebenza futhi iqondile. Isakhiwo sayo sihlanganisa umphongolo oyicylindrical nesikulufu esijikelezayo, esisebenza ndawonye ukucubungula impahla ye-PVC. I-screw's helical grooves iqinisekisa ukuxutshwa okufanele nokuncibilika kwezinto, kuyilapho umgqomo uhlinzeka ngendawo elawulwayo yokukhishwa.

Ukucaciswa okubalulekile kobuchwepheshe kwalezi zingxenye kuhlanganisa:

| Ukucaciswa | Imininingwane |

|---|---|

| Ububanzi | Ф16-Ф300 |

| I-Aspect ratio | L/D=15-40 |

| Izici Zesakhiwo | Isakhiwo esilula, izindleko eziphansi, ukuxuba okuhle kanye nekhono leplastiki |

Lezi zicaciso zigqamisa ukuguquguquka komklamo, okuwenza ulungele izinhlelo zokusebenza ezahlukahlukene ze-PVC. Ukwengeza, ucwaningo lwezimboni lubonise ukuthi ukuziphatha kokushelela kodonga kuma-extruder anesikulufu esisodwa kuwathinta kakhulu amazinga okugeleza. Amamodeli athuthukiswe izinga lokugeleza, ukwehla kokucindezela, nesivinini sesikulufu athuthukisa ukusebenza kwe-extrusion.

Izinto kanye Nekhwalithi Yokwakha

Izinto ezisetshenziswa ekukhiqizeni ipayipi le-PVC imiphongolo yesikulufa eyodwa idlala indima ebalulekile ekuqineni nasekusebenzeni kwayo. Imiphongolo eminingi yenziwe nge-38crMoAIA, insimbi enamandla amakhulu alloy eyaziwa ngokumelana nokugqokwa kwayo okuhle kakhulu kanye nokuqina. Indawo ithola ukwelashwa kwe-nitriding ukuze kuthuthukiswe ubulukhuni nokwelula impilo yomgqomo.

Izinto ezibonakalayo ezibalulekile zifaka:

- Ukuqina KobusoI-HV≥900

- I-Nitride Layer DepthUbukhulu: 0.5-0.8mm

Lezi zici ziqinisekisa ukuthi umgqomo ungamelana namazinga okushisa aphezulu kanye nezingcindezi ngesikhathi senqubo yokukhipha. Ikhwalithi yokwakha eqinile inciphisa ukuguga, yehlise izindleko zokulungisa kanye nesikhathi sokuphumula. Abakhiqizi abafana ne-Zhejiang Jinteng Machinery Manufacturing Co., Ltd. basebenzisa imishini ye-CNC ethuthukisiwe nobuchwepheshe bokwelapha ukushisa ukuze bafinyelele la mazinga aphezulu.

Amasistimu wokushisisa nokupholisa

Amasistimu wokushisisa nokupholisa asebenzayo abalulekile ekugcineni amazinga okushisa angashintshi phakathi nenqubo yokukhipha. Isistimu yokushisisa yomphongolo iqinisekisa ukuthi impahla ye-PVC iyancibilika ngokulinganayo, kuyilapho isistimu yokupholisa ivimbela ukushisa ngokweqile futhi igcina ikhwalithi yomkhiqizo.

Ucwaningo oluhlaziya imiphumela yesivinini sesikulufu nezinga lokushisa ekusebenzeni kwe-extrusion lubonise ukubaluleka kokulawula izinga lokushisa okunembile. Ama-transducer okucindezela izinga lokushisa afakwe ngaphambi nangemuva kwezimo zepuleti le-breaker ngesikhathi sangempela, okuqinisekisa ukusebenza kahle. Ukulungiswa kwesivinini sesikulufu, izinga lokushisa elincibilikayo, nezinga lokugeleza kuthinta ngokuqondile ikhwalithi yomkhiqizo wokugcina.

Lezi zinhlelo azithuthukisi ukusebenza kahle kuphela kodwa futhi zithuthukisa ukuhambisana kwenqubo yokukhipha, okwenza imiphongolo yesikulufa yepayipi elilodwa le-PVC ibe ukukhetha okuthembekile kubakhiqizi.

Isebenza kanjani i-PVC Pipe Single Screw Barrels

Indima Yesikulufu ku-PVC Extrusion

Isikulufu emgqonyeni wesikulufa wepayipi elilodwa le-PVC sisebenza njengomgogodla wenqubo yokukhipha. Isiza ukunyakaza, ukuncibilika, kanye nokuxutshwa kwezinto ze-PVC ngaphakathi komgqomo. Idizayini ye-helical yesikulufu iqinisekisa ukusatshalaliswa okufanayo kokushisa nokucindezela, okubalulekile ekuzuzeni ikhwalithi yomkhiqizo engaguquki.

- Imiklamo yezikulufo elungiselelwe ibonise ukuthuthuka okumangalisayo kokusebenza kahle. Ngokwesibonelo:

- Ukukhiqizwa kokukhiqiza kuphindwe kabili kusuka kumathani angu-4.5 kuya ku-8.5 amathani ngokushintshana kuhlelo lokusebenza lomhlaba wangempela.

- Ukuvumelana nezimo okuthuthukisiwe ekucubunguleni izinto ezihlukahlukene nezithasiselo kuthuthukise ikhwalithi yomkhiqizo.

- Imiklamo yezikulufo efanelanisiwe inciphisa ukusetshenziswa kwezinto, ikhulisa inzuzo.

Ucwaningo lwezazi luqhubeka lugcizelela ukubaluleka kokuklama isikulufu. Amamodeli ezibalo nezifundo zokuhlola ziqinisekisa ukuthi izikulufu zokuthibela zithuthukisa ukusebenza kokuncibilika kanye nemiphumela yokukhipha. Le miphumela igqamisaindima ebalulekile yesikulufaekuqinisekiseni ukusebenza kahle nokuthembeka kokukhiqizwa kwamapayipi e-PVC.

Inqubo yokuncibilika nokuxuba

Iukuncibilika nokuxuba inqubongaphakathi kwepayipi le-PVC umphongolo wesikulufa esisodwa kuwukulandelana okwenziwe ngokucophelela. Njengoba impahla ye-PVC ingena emgqonyeni, ukuzungezisa kwesikulufu kudala ukungqubuzana nokushisa, kuncibilike kancane kancane. Ama-helical grooves kusikulufu asiza ukuxubana okuphelele, ukuqinisekisa ukuthi izithasiselo nezigcwalisi zisatshalaliswa ngokulinganayo.

- Ucwaningo oluhlola ama-barrier-screw extruder luveza ukusebenza kahle kwawo ekuthuthukiseni i-polymer extrusion, okuhlanganisa i-PVC.

- Ucwaningo lokulandelana kwepulasitiki luhlinzeka ngedatha yokuhlola esekela ukwenziwa kahle kwezinqubo ze-extrusion.

Ukulawula izinga lokushisa kudlala indima ebalulekile kule nqubo. Ukulungiswa okunembayo kwesivinini sesikulufu kanye nezinga lokushisa elincibilikayo kuqinisekisa ukuthi okokusebenza kufinyelela ukuvumelana okufunayo. Le ndlela yokucophelela inciphisa amaphutha futhi ithuthukise ikhwalithi yomkhiqizo wokugcina.

Ukuqinisekisa Ukusebenza Nokungaguquguquki

Ukusebenza kahle nokungaguquguquki kubaluleke kakhulu ekukhishweni kwamapayipi e-PVC. Abakhiqizi basebenzisa izindlela ezithuthukisiwe zokugcina ukuqina kwenqubo nokunciphisa ukuhlukahluka. I-Statistical Process Control (SPC) ihlonza ukuhluka futhi izinze izinqubo, kuyilapho indlela ye-DMAIC ye-Six Sigma's DMAIC iqhubeka iphucula amakhono okukhiqiza.

- Idatha yomhlaba wangempela ibonisa umthelela wokuthuthukiswa kwenqubo:

- Isistimu yokutholwa kwedatha yehlise amanani okulahlwa kusuka ku-15% kuya ku-5% phakathi nezinyanga ezintathu.

- Ukuqapha kwesikhathi sangempela kuvimbele imikhiqizo engaphandle kwe-spec, kuqinisekisa amazinga aphezulu.

- Ukonga kwezindleko kwalolu hlelo kwabonakala njengoba lazikhokhela ngokushesha ngokuncipha kokumosha.

Lawa maqhinga awathuthukisi ukusebenza kahle kuphela kodwa futhi aqinisekisa ikhwalithi yomkhiqizo engaguquki, okwenza imiphongolo yepayipi elilodwa le-PVC ibaluleke kakhulu ekukhiqizeni kwesimanje.

Izinzuzo ze-PVC Pipe Single Screw Barrels

Ubulula kanye Nezindleko-Ngempumelelo

Imiphongolo yesikulufu yepayipi elilodwa le-PVC aziwa kabanzi ngokuklama kwawo okuqondile nokusebenza ngendlela eyongayo. Isakhiwo sabo esilula sinciphisa ukwehluleka kwemishini, sibenze balungele abakhiqizi abayifunayoukusebenza okuthembekile nokuzinzile. Ama-extruder angama-screw single ahlala eletha ingcindezi efanayo kanye namazinga okukhiphayo, abalulekile ekukhiqizeni amapayipi ekhwalithi ephezulu we-PVC.

- Izinzuzo ezibalulekile zifaka:

- Kwehlisiwe ukutshalwa kwezimali kwasekuqaleni ngenxa yomklamo wazo ongaxakile.

- Izindleko zokusebenza eziphansi uma ziqhathaniswa nezinhlelo eziyinkimbinkimbi.

- Ukufaneleka okuphezulu kwemisebenzi ejwayelekile yokucubungula, efana nepayipi nokukhiqizwa kweshidi.

Ngo-2024,ama-extruder wesikulufa esisodwakubalwe u-62.7% wemali engenayo yemakethe, okugcizelela ukubusa kwabo emisebenzini emincane ukuya kwesezingeni eliphakathi. Ukufinyeleleka kwabo nokuthembeka kubenza babe ukukhetha okuthandwayo kubakhiqizi abaningi.

Isondlo Nokuqina

Ukuqina kwemiphongolo yesikulufu yepayipi elilodwa le-PVC kuvela ekwakhiweni kwawo okuqinile nezinto ezithuthukile. Ama-alloys aqine kakhulu, ahlanganiswe nama-coatings aqinile, athuthukisa ukumelana nokuguga nokugqwala okubangelwa imvelo yokuhuzuka kwe-PVC.

| Isici | Incazelo |

|---|---|

| Uhlobo Lwepulasitiki | Imvelo yokubola ye-PVC ithinta ukugqokwa. |

| I-Harden Coating | Ama-coatings athuthukisa ukumelana nokuphila isikhathi eside. |

| Izilungiselelo Zenqubo | Izinga lokushisa elifanele nokucindezela kunciphisa ukuguga. |

Ukuqalisa izinhlelo zokulungisa ezivikelayo kwandisa isikhathi sokuphila sale miphongolo. Ukuhlolwa kokuqondanisa okuvamile nokuqeqeshwa kwezisebenzi ngokulinganisa ukuguga kuqinisekisa ukusebenza okungaguquki ngokuhamba kwesikhathi.

Ukuqhathanisa ne-Twin Screw Barrels

Imiphongolo yesikulufu esisodwa ihluke kakhulu kumasistimu ngezikulufu ezingamawele ekwakhiweni, izindleko, nokugcinwa. Ngenkathi ama-twin screw barrel ehamba phambili ezinhlelweni ezikhethekile, imiphongolo yesikulufu esisodwa inikeza ubulula nokuthembeka kwezinqubo ezijwayelekile.

| Isici | Ama-Single Screw Barrels | Ama-Twin Screw Barrels |

|---|---|---|

| Idizayini | Kulula, kunciphisa ukwehluleka komshini | Inkimbinkimbi, ingozi yokwehluleka ephezulu |

| Isondlo | Kudingeka ubungcweti obulula, obuncane | Ukulungisa okuyinkimbinkimbi |

| Izindleko Zokusebenza | Okuncane ngenxa yokuklama okuphumelelayo | Iphakeme ngenxa yobunkimbinkimbi |

Imiphongolo yesikulufu esisodwa nayo ihlinzeka ngokulawula izinga lokushisa okulula futhi ifaneleka kakhulu ekushintsheni izinhlobo zokumboza. Lezi zinzuzo zizenza kube ukukhetha okusebenzayo kubakhiqizi ukubeka phambili ukuphumelela kwezindleko nokusebenza kahle.

Izicelo ze-PVC Pipe Single Screw Barrels

Ukwakhiwa kanye namapayipi

Ipayipi le-PVC imiphongolo yesikulufu esisodwaibamba iqhaza elibalulekile embonini yokwakha neyokufaka amapayipi amanzi. Le miphongolo yenza kube lula ukukhiqiza amapayipi e-PVC ekhwalithi ephezulu, asetshenziswa kabanzi ukuhambisa amanzi, ukuthuthwa kwamanzi kanye nezinhlelo zokukhucululwa kwendle. Ikhono labo lokukhiqiza amapayipi ngokuqina kodonga olungaguquki kanye nezindawo ezibushelelezi kuqinisekisa ukusebenza okuthembekile ekusetshenzisweni okudingayo.

Abakhi nosonkontileka bakhetha amapayipi e-PVC ngenxa yemvelo yawo engasindi, ukumelana nokugqwala, kanye nokuwafaka kalula. Ukunemba okunikezwa ngemiphongolo yesikulufu eyodwa kuqinisekisa ukuthi amapayipi ahlangabezana nezindinganiso eziqinile zemboni, okuwenza abe yinketho ethenjwayo kumaphrojekthi okuhlala, ezohwebo, kanye nezimboni.

Amapayipi kagesi kanye namapayipi embonini

Amapayipi kagesi namasistimu amapayipi ezimboni ancike kakhulu kumapayipi e-PVC akhiqizwa kusetshenziswa imiphongolo yesikulufu esisodwa. Le miphongolo iqinisekisa ukufana kobukhulu bamapayipi, okubalulekile ezinhlelweni ezidinga ukufakwa okunembayo nokuxhumeka.

Izifundo zokusebenza zigqamisa umthelela wamapharamitha ahlukahlukene kuzakhiwo ze-extrudate phakathi nenqubo ye-extrusion. Ithebula elingezansi lifinyeza okutholakele okubalulekile:

| Ipharamitha | Umthelela ku-Extrudate Properties |

|---|---|

| Amazinga we-DDGS | Ukwehla okukhulu kwengcindezi yokufa enamazinga aphezulu |

| Okuqukethwe Umswakama | Umehluko omkhulu ngesilinganiso sombala kanye nokunwetshwa |

| I-Die Dimensions (izilinganiso ze-L/D) | Ithinta ingcindezi yokufa kanye nesilinganiso sokunwetshwa |

| Izilinganiso zokucindezelwa kweScrew | Ukucindezela okuphezulu kuholela ekushintsheni okuphawulekayo kwezakhiwo |

| Izimo Zokucubungula | Ithonya i-extruder torque, ingcindezi yokufa, nezinga lokugeleza okukhulu |

Le mininingwane ikhombisa ukuthi izimo zokucubungula ezithuthukisiwe kanjani kanye nemiklamo yezikulufu ezithuthukisa ikhwalithi yamapayipi e-PVC okusebenza kukagesi nezimboni. Amapayipi avelayo abonisa ukuqina okuhle kakhulu, ukumelana namakhemikhali, nokuzinza kwe-thermal, okuwenza alungele ukuvikela izintambo zikagesi kanye nokuthutha uketshezi lwezimboni.

Okunye Ukusetshenziswa Okuthize Kwemboni

Ngaphandle kokwakhiwa kanye nezicelo zikagesi, ipayipi le-PVC imiphongolo yesikulufa esisodwa isekela izimboni ezikhethekile. Amasistimu okunisela ngenkasa ezolimo ahlomula ezintweni ezingasindi futhi ezimelana nesimo sezulu zamapayipi e-PVC. Emkhakheni wezimoto, lawa mapayipi asetshenziselwa izinhlelo zokudlulisa uketshezi ngenxa yokumelana kwawo namakhemikhali nokuguquguquka.

Imboni yokudla neziphuzo iphinde isebenzise amapayipi e-PVC ukuthutha uketshezi olungenabuthi futhi oluhlanzekile. Ukuguquguquka kwemiphongolo yesikulufu esisodwa kuvumela abakhiqizi ukuthi bahlele izakhiwo zamapayipi ukuze bahlangabezane nezidingo ezihlukile zemboni ngayinye, baqinisekise ukusebenza kahle nokuthembeka.

Ipayipi le-PVCimiphongolo yesikulufa esisodwayisibonelo sobunjiniyela bokunemba, ukuhlanganisa i-screw geometry elungiselelwe kanye nezindawo zokusebenza ukuze kuthuthukiswe ukusebenza kahle kwe-extrusion. Idizayini yabo eqinile iqinisekisa amaphrofayili okushisa okuncibilika angaguquguquki, ithuthukisa ikhwalithi yomkhiqizo futhi inciphise imfucuza. Le miphongolo idlala indima ebalulekile ekwenziweni kwamapayipi e-PVC, isekela izinhlelo zokusebenza ezihlukene kuyo yonke imikhakha yezokwakha, yokufaka amapayipi, kanye nezimboni, kuyilapho ishayela izinqubo zokukhiqiza ezingabizi kakhulu nezithembekile.

FAQ

Ingakanani impilo yomgqomo wesikulufa wepayipi elilodwa le-PVC?

Ubude bempilo buncike ekusetshenzisweni nasekulungisweni. Imiphongolo yekhwalithi ephezulu, njengaleyo eyenziwe ngensimbi eyingxubevange engu-38crMoAIA, ngokuvamile ihlala iminyaka eminingana ngokunakekelwa okufanele.

Ukulawulwa kwezinga lokushisa kuyithinta kanjani ikhwalithi ye-extrusion?

Ukulawula izinga lokushisa okunembile kuqinisekisa ukuncibilika okufanayo nokuxuba impahla ye-PVC. Lokhu kunciphisa amaphutha futhi kuthuthukisa ukuhambisana komkhiqizo wokugcina.

Ingabe imiphongolo yesikulufa eyodwa ingaphatha ukwakheka okuhlukile kwe-PVC?

Yebo, imiphongolo yesikulufa eyodwa ivumelana nokwakheka okuhlukahlukene kwe-PVC. Idizayini yabo isekela ukucubungula okusebenzayo kwezithasiselo nama-filler, okuqinisekisa ukusebenza kahle kwe-extrusion.

Isikhathi sokuthumela: Jun-05-2025