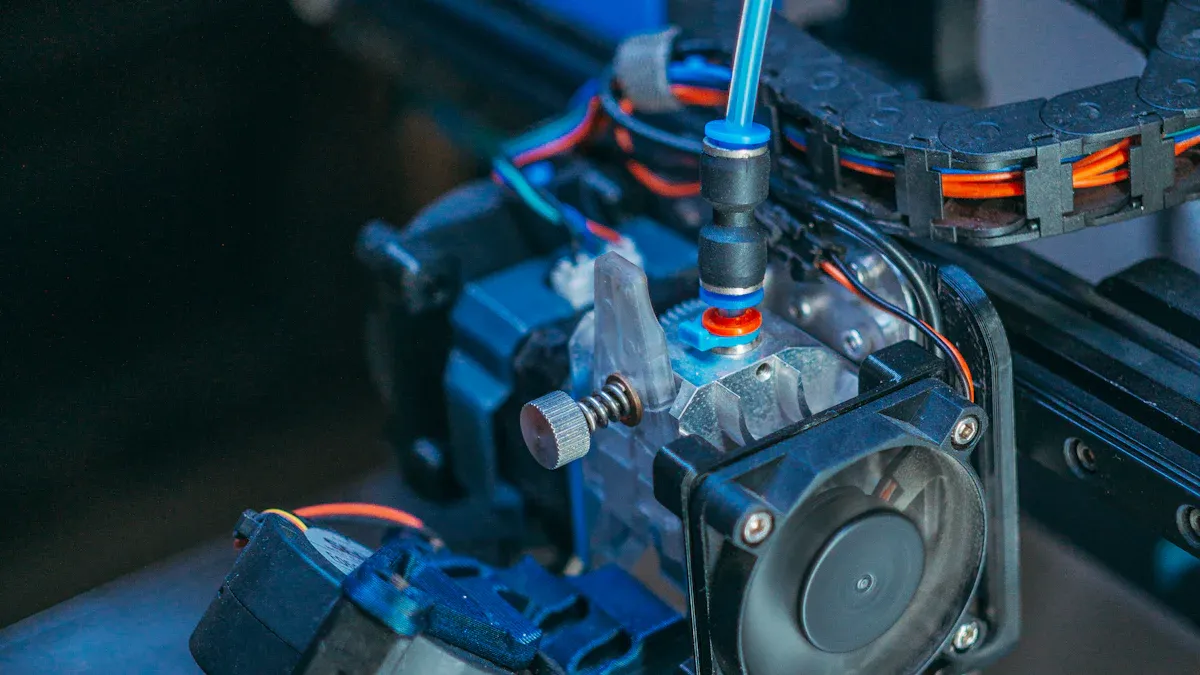

Abakhiqizi bakhetha ukuthuthukiswa okubalulekile kokukhiqizwa kwenqwaba ye-Twin Screw Plastic Extruder ukuze bathuthukise ukusebenza kahle nokuqina. Ukuthuthukiswa okujwayelekile kufaka phakathi ubuchwepheshe obungasomisi, imiphongolo yesikwele emisha, nezinto eziphinde zenziwe kabusha, njengoba kukhonjisiwe ngezansi:

| Thuthukisa Isici | Incazelo | Izinzuzo |

|---|---|---|

| Ubuchwepheshe obungasomisi | Isusa izinyathelo zokumisa | Ilondoloza amandla nesikhala |

| Izigqoko Ezintsha Zesikwele | Izikhathi zokushisa ezisheshayo | Yehlisa isikhathi sokuphumula |

| Izingxenye Ezakhiwe Kabusha | Idizayinelwe impilo ende | Yandisa ukusebenza kahle |

Ubuchwepheshe obuthuthukisiwe be-CNC kuI-Twin Plastic Screw BarrelfuthiI-Extrusion Machine Single Screw Barelukukhiqiza kwandisa ukunemba, ukuqina, futhi kunciphisa ukulungiswa. Iplastic twin screw extruderizinzuzo ezivela kulokhu kuthuthukiswa ngamandla okuxuba athuthukisiwe kanye nokuphathwa kwezinsiza okuthuthukisiwe.

Ukuthuthukiswa Okubalulekile Kokukhiqizwa Okuningi Kwe-Twin Screw Plastic Extruder Bulk

Izinselelo Zokusebenza Ekukhiqizeni Ivolumu Ephezulu

Abakhiqizi babhekana nezithiyo ezimbalwa lapho besebenzisa amasistimu e-Twin Screw Plastic Extruder okukhiqiza ngobuningi. Ukukhuphuka kwezindleko zezinto kanye namandla kudala ingcindezi yokuthuthukisa ukusebenza kahle. Intengo yensimbi engagqwali yezinga eliphezulu inyuke ngo-14% kusukela ngo-2022 kuya ku-2023. Izindleko zikagesi zemishini yezimboni zikhuphuke ngo-11% eYurophu. Lezi zinguquko ziphoqa izinkampani ukuthi zifune ukuphathwa kangcono kwamandla kanye nokusetshenziswa kwezinto ezibonakalayo.

Amasistimu e-extruder aphelelwe yisikhathi anomthelela emazingeni aphezulu kadoti. Isibonelo, imfucuza ekufakweni kwamapayipi e-PVC aqinile ngokuvamile alinganiselwa ku-1.5%. Izikulufu ezigugile zingakhuphula leli zinga lifike ku-10%, okuholela ekwenyukeni kwezindleko zokukhiqiza. Ukungabhekani nokugqoka ngezikulufu kubangela imiphumela ebizayo kubakhiqizi.

Ithiphu: Ukunakekelwa okuvamile kanye nokuthuthukiswa okufika ngesikhathi kusiza ukunciphisa udoti nokulawula izindleko ekusebenzeni kwevolumu ephezulu.

Abakhiqizi baphinde bahlangabezane nezinselele ngokusebenza nokulawula izinga lokushisa. Ukuthuthukiswa okufana nezinhlelo zokupholisa ezinomfutho ophezulu kanye nama-insulation gaskets kuthuthukisa ukushintshaniswa kokushisa nokugcina izimo zokucubungula ezizinzile. Ukusebenzisa ukuphakela okuseceleni kukhulisa amazinga okulayishwa kwesigcwalisi, kuyilapho izici zesikulufu sephimbo elide zikhulisa ukugeleza kokubalulekile futhi zivimbela ukuvinjwa.

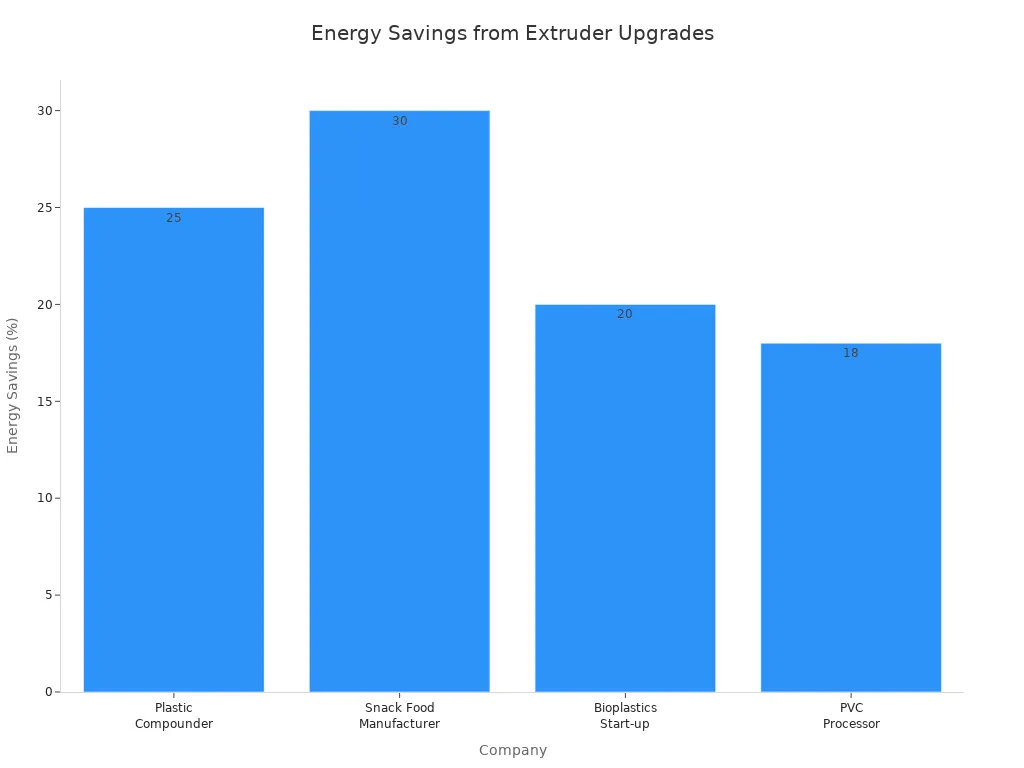

Ukusetshenziswa kwamandla kusewukukhathazeka okubalulekile. Ukuthuthukisa idizayini yesikulufu nokusebenzisa amasistimu okulawula izinga lokushisa athuthukile kuholela ekongeni amandla okubalulekile. Ukufakwa kabusha ngobuchwepheshe be-servo motor kuthuthukisa ukusebenza kahle. Ukulungiswa kwedizayini yesikulufu nokucushwa kokuphakela kungaba nomthelela oqondile ekusebenziseni amandla emishini.

Kungani Ukuthuthukiswa Kuphuthuma Emakethe Yanamuhla

Imakethe yobuchwepheshe be-Twin Screw Plastic Extruder iyaqhubeka nokuvela ngokushesha. Abakhiqizi kufanele baphendule kumathrendi amasha kanye nezidingo zamakhasimende ukuze bahlale bencintisana. Ithebula elingezansi ligqamisa amathrendi emakethe aqhuba isidingo sokuthuthukisa ngokushesha:

| Uhlobo Lwethrendi | Incazelo |

|---|---|

| Ukusebenza okuningi | Ama-twin screw extruder manje anikezela nge-polymer, ukudla, okuphakelayo, nezinye izimboni. |

| Ukukhiqizwa okukhulu | Amayunithi amakhulu anciphisa izindleko futhi asekela izidingo zemboni ye-petrochemical. |

| Ukunemba | Imikhiqizo yenani eliphezulu idinga i-extrusion enembile, njengamafilimu anezingqimba eziningi e-extruded co-extruded. |

| Ubuchwepheshe obuhlakaniphile | Ukuqapha nokulawula kwesikhathi sangempela kuthuthukisa ukunemba nokuzinza. |

Amakhasimende alindele izinga eliphezulu lomkhiqizo nokungaguquguquki. Amasistimu we-Twin Screw Plastic Extruder aletha ukuxubana okuphakeme nokususa umoya, okunciphisa amaphutha futhi kuthuthukise okukhiphayo. Lezi zici zibalulekile ezingxenyeni zobuchwepheshe ezinezidingo eziqinile zekhwalithi. Ukuthuthukiswa kobuchwepheshe be-extruder kuthuthukisa ukunemba nokulawula, kuyilapho amasistimu ahlakaniphile evumela ukulungiswa kwesikhathi sangempela kumapharamitha abalulekile.

Abakhiqizi abatshala imali kulwazi olubalulekile lokuthuthukisaizinzuzo ezibalulekile. Izindleko zokunakekela eziphansi kanye nesikhathi esincishisiwe sokuphumula kubangela ukonga isikhathi eside. Imiklamo eqinile iqinisekisa ukuqina nokukhiqiza okuthuthukisiwe, okwenza izinhlelo ezithuthukisiwe ze-Twin Screw Plastic Extruder zibe ukukhetha okuthembekile kokukhiqiza ngobuningi.

I-CNC Ethuthukisiwe kanye Nobuchwepheshe Be-Nitriding Ye-Twin Screw Plastic Extruder

Ukunemba kanye Nokungaguquguquki kwe-CNC Ekukhiqizeni I-Extruder

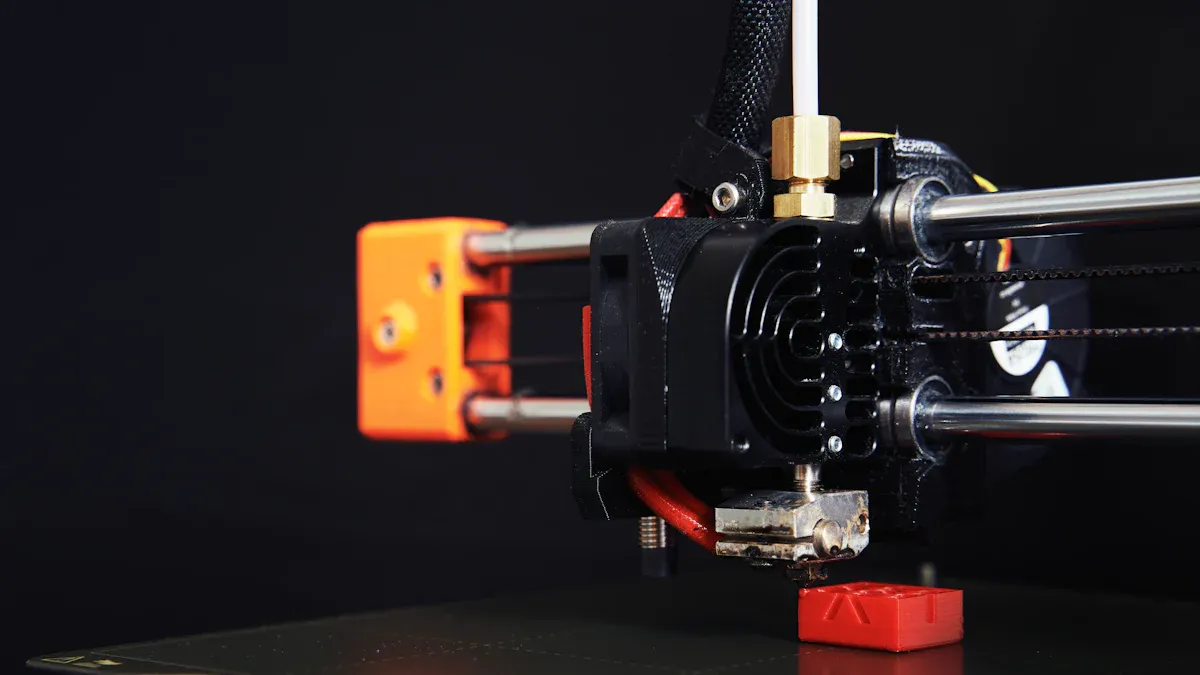

Ukukhiqiza kwesimanje kudinga ukunemba okuphezulu nokuphindaphindeka. Ubuchwepheshe obuthuthukisiwe be-CNC buletha lezi zimfanelo zezingxenye ze-Twin Screw Plastic Extruder. Imishini ye-CNC isebenzisa isilawuli sekhompyutha ukuze ilolonge izikulufu nemiphongolo enezilinganiso eziqondile. Le nqubo iqinisekisa ukuthi ingxenye ngayinye ilingana kahle futhi isebenza ngokuthembekile ekukhiqizweni kwevolumu ephezulu.

Izici ezibalulekile zezinhlelo ze-CNC ezithuthukisiwe zifaka ubuhlakani bokwenziwa, izinzwa ezithuthukile, nama-extruder aqhutshwa yi-servo. Lezi zici zisebenza ndawonye ukuze kuthuthukiswe inqubo ye-extrusion. Isibonelo, ubuhlakani bokwenziwa buhlaziya idatha futhi bubikezele imiphumela, buvumele ukulungiswa kwesikhathi sangempela kuzinga lokushisa nokucindezela. Izinzwa ezithuthukile ziqapha amapharamitha abalulekile, zinikeza impendulo esheshayo yokulungisa. Ama-extruder aqhutshwa yi-Servo alawula isivinini sesikulufu nokucindezela, okuqinisekisa ukufana emkhiqizweni wokugcina. Izifudumezi ezisebenza kahle kakhulu nezinhlelo zokulawula ezizenzakalelayo zithuthukisa ukusetshenziswa kwamandla kanye nekhwalithi yomkhiqizo.

| Isici | Incazelo |

|---|---|

| I-Artificial Intelligence (AI) | Ilungiselela izinqubo ze-extrusion ngokuhlaziya idatha, ukubikezela imiphumela, kanye nokunika amandla ukulungiswa kwesikhathi sangempela kumapharamitha afana nezinga lokushisa nokucindezela. |

| Izinzwa Ezithuthukile | Iqapha izinga lokushisa, ingcindezi, namazinga okugeleza kwezinto ngokunemba okuphezulu, inikeze impendulo yesikhathi sangempela yokulungiswa kwamanje. |

| Ama-Extruder aqhutshwa yi-Servo | Inikeza ukunemba ekulawuleni isivinini sesikulufu nokucindezela, iqinisekisa ukufana emikhiqizweni ekhishiwe. |

| Ukusebenza Kwamandla | Izifudumezi ezisebenza kahle kakhulu zinciphisa ukulahleka kwamandla futhi zinikeze ukufudumeza okusheshayo, okufanayo ukuze inqubo ingaguquguquki. |

| Okuzenzakalelayo Control Systems | Lungisa ngokunamandla amapharamitha enqubo ngesikhathi sangempela ukuze uthuthukise ukusebenza kahle nekhwalithi yomkhiqizo. |

Lezi ntuthuko zisiza abakhiqizi ukuthi bathole imiphumela engaguquki, banciphise ukumosha, futhi bagcine amazinga aphezulu kuwo wonke amaqoqo.

I-Nitriding Yokuqina Okuthuthukisiwe kanye Nokumelana Nokugqoka

Ubuchwepheshe be-nitriding budlala indima ebalulekile ekwandiseni isikhathi sokuphila sezikulufu nemiphongolo kumasistimu we-Twin Screw Plastic Extruder. Le nqubo iphatha ingaphezulu lensimbi endaweni enenitrogen ephezulu cishe ku-950°F (510°C). Umphumela uba ungqimba lwangaphandle oluqinile olunokuqina kwekesi phakathi kuka-55 no-65 Rc. Lesi singqimba esiqinile simelana nokugqoka okuvela ezintweni ezilimazayo futhi sigcina amandla aso ngokuhamba kwesikhathi.

I-Nitriding inikeza izinzuzo ezimbalwa ngaphezu kwezinye izindlela zokwelapha ezingaphezulu. Inikeza ukumelana nokugqokwa okungcono kune-carburizing, ngesendlalelo esine-nitrided esibonisa ukuguga okuphansi okungama-50% ngaphansi kwemithwalo efanayo. Izifundo ze-Tribological ziqinisekisa ukuthi i-nitriding idlula i-carburizing, noma ngabe ungqimba lwe-carburized lushubile. Inqubo idala ikesi elincanyana, eliqinile elincipha kancane kancane ebulukhunini, elisiza ukuvikela emonakalweni ongaphezulu.

- Ubuchwepheshe be-Nitriding bunikeza ukumelana nokugqoka okuphezulu uma kuqhathaniswa nokungcwatshwa kwe-carburizing yezikulufu ze-extruder nemiphongolo.

- Isendlalelo esine-nitrided sibonisa ukuguga okuphansi okungu-50% ngaphansi kwezimo ezifanayo zomthwalo.

- Ucwaningo lwe-Tribological lubonisa ukuthi i-nitriding inenzuzo kakhulu kune-carburizing ngenxa yezakhiwo ezigugile kangcono naphezu kongqimba olujiyile lwe-carburized.

- I-Nitriding ihilela ukwelapha izikulufu noma imiphongolo endaweni enenitrogen ephezulu ecishe ibe ngu-950°F (510°C), okuholela ebukhuni obukhulu (55 – 65 Rc).

- Inqubo ye-nitriding idala ikesi elincanyana elinciphisa ubulukhuni, elisiza ukugcina ukumelana nokuguga ngokumelene nezinto ezilimazayo.

- Izinsimbi ezifanele ze-nitriding, njenge-Crucible Nitriding 135, zithuthukisa ubulukhuni obuzuzwe ngenqubo.

I-Nitriding iphinde isize ekuvimbeleni izindlela zokwehluleka ezivamile ezingxenyeni ze-extruder. Lezi zihlanganisaukukhathala okugoba umjikelezo ophansi, ukuphuka okufiphalayo, nokukhathala kokuxhumana. Ithebula elingezansi libonisa lezi zindlela zokwehluleka nokuthi i-nitriding ibhekana kanjani nazo.

| Imodi yokwehluleka | Incazelo |

|---|---|

| Ukukhathala kokugoba komjikelezo ophansi | Indlela yokwehluleka okuyinhloko eholela ekuqhekekeni okufiphala kwegiya le-pinion. |

| I-Brittle fracture | Okubangelwa ukukhathala okugoba umjikelezo ophansi, okubonisa iphuzu lokuhluleka elibalulekile. |

| I-Carburization kanye nokuqedwa kwendawo | I-carburization yecala eleqile kanye nokuqedwa kahle kwendawo kwehlisa umkhawulo wokukhathala, okunomthelela ekuqhekekeni. |

| Xhumana nokukhathala | Okujwayelekile ekwehlulekeni kwamagiya, okuholela ezinkingeni ezibalulekile zokusebenza. |

| Ukukhathala okugoba izinyo | Enye indlela evamile yokwehluleka kwamagiya, evame ukukhuliswa ukuphathwa kabi kwezinto ezibonakalayo. |

Ngokukhetha i-nitriding, abakhiqizi bandisa ukuqina kwemishini yabo ye-Twin Screw Plastic Extruder futhi banciphise ubungozi bokuwohloka okumba eqolo.

Izinyathelo Ezisebenzayo Zokuthuthukisa Ama-Twin Screw Plastic Extruders Akhona

Ukuthuthukisa izinhlelo ezikhona ze-Twin Screw Plastic Extruder kudinga ukuhlela ngokucophelela. Abakhiqizi kufanele baqale bahlole isimo samanje semishini yabo. Badinga ukukhomba ukuthi yiziphi izingxenye ezingazuza kakhulu kumishini ye-CNC noma ukwelashwa kwe-nitriding.

Ukucatshangelwa kwezindleko kudlala indima enkulu ekuthuthukisweni kwezinqumo. Usayizi we-extruder, izindleko zezinto ezibonakalayo, nobunkimbinkimbi bokukhiqiza konke kuthinta ukutshalwa kwezimali okuphelele. Ama-extruder amancane anezindleko eziphansi zezinto ezibonakalayo kanye nezidingo ezilula zokukhiqiza. Ama-extruder aphakathi nendawo amakhulu adinga izinsiza ezengeziwe kanye nobuchwepheshe obuphambili, okwandisa izindleko.

| Usayizi we-Extruder | Izindleko Zempahla | Inkimbinkimbi Yokukhiqiza |

|---|---|---|

| Encane | Phansi | Kulula |

| Maphakathi | Kuphakathi | Kuphakathi |

| Okukhulu | Phezulu | Inkimbinkimbi |

Abakhiqizi kufanele futhi bacabangele ukuhambisana kwezinto kanye namandla okukhiqiza. Ama-extruder ahlukene aphatha izinto ezahlukahlukene, ezingathinta izindleko zokuthuthukisa. Imisebenzi yomthamo omkhulu ingase idinge izici ezithuthukisiwe, ezifana nemishini ezenzakalelayo namasistimu awonga amandla. Nakuba lezi zici zandisa izindleko zokuqala, ngokuvamile ziholela ekongeni isikhathi eside ngokunciphisa ukulungiswa nokusetshenziswa kwamandla.

- Ukuhambisana kwezinto kuthinta izindleko zokuthuthukisa.

- Amandla okukhiqiza anquma isidingo sama-extruder aphezulu.

- Izici zobuchwepheshe, njengokuzenzakalela nokusebenza kahle kwamandla, zidinga ukutshalwa kwezimali okuphezulu kokuqala kodwa zinikeza ukonga kwesikhathi eside.

Ithiphu: Ukubambisana nabakhiqizi abanolwazi, njenge-Zhejiang Jinteng Machinery Manufacturing Co., Ltd., kuqinisekisa ukufinyelela ku-CNC ethuthukisiwe kanye nobuchwepheshe be-nitriding. Ubuchwepheshe babo busiza ukwenza lula inqubo yokuthuthukisa futhi bakhulise ukusebenza kwemishini.

Ngokulandela lezi zinyathelo, abakhiqizi bangenza izinhlelo zabo ze-Twin Screw Plastic Extruder zibe zesimanjemanje, bathuthukise ukusebenza kahle, futhi banwebe ukuphila kwemishini.

Abakhiqizi bathola ukusebenza kahle okuphezulu nokusimama ngokuthuthukisa ama-extruder nge-CNC kanye nobuchwepheshe be-nitriding. Ithebula elingezansi ligqamisa izinzuzo zesikhathi eside:

| Zuza | Incazelo |

|---|---|

| Ukusebenza Okuphezulu Kokukhiqiza | Ithuthukisa ukusebenza kahle, inwebe impilo yesevisi, futhi yandise isikhathi sokusebenza esiqhubekayo semishini. |

| Ukuvumelana nokunemba | Ikhiqiza izingxenye ezinokubekezelela okuqinile kanye nokunemba okuphezulu kobukhulu bokukhiqiza okungaguquki. |

| Izindleko-Ngempumelelo | Yehlisa udoti wezinto ezibonakalayo, inciphise udoti, futhi ikhulise ukusetshenziswa kwezinto. |

Izinyathelo ezilandelayo: Tshala imali kubuchwepheshe obuthuthukisiwe, gxila ezintweni ezivumelana nemvelo, futhi uqeqeshe o-opharetha ukuze uthole ukusebenza okuhle kwesistimu.

FAQ

Yiziphi izinzuzo ubuchwepheshe be-CNC obuletha kuzo ekuthuthukisweni kwe-twin screw extruder?

Ubuchwepheshe be-CNCiqinisekisa ukukhiqiza okunembayo. Ithuthukisa ukungaguquguquki kwengxenye futhi inciphise imfucuza. Abakhiqizi bathola ukusebenza kahle okuphezulu kanye nekhwalithi yomkhiqizo engcono ngokuthuthukiswa kwe-CNC.

I-nitriding ikwandisa kanjani impilo yezikulufu ze-extruder nemiphongolo?

I-Nitriding idala isendlalelo sendawo eqinile. Lesi singqimba simelana nokuguga nokuhuzuka. Okokusebenza kuhlala isikhathi eside futhi kudinga ukushintshwa okungajwayelekile.

Ingabe ama-extruder akhona angathuthukiswa nge-CNC kanye nobuchwepheshe be-nitriding?

Yebo. Abakhiqizi bangabuyisela kabusha amasistimu amanje. Ukuthuthukiswa kuthuthukisa ukusebenza, kukhuphula ukuqina, futhi kunciphise izindleko zokulungisa.

Ithiphu: Xhumana nabakhiqizi abanolwazi ukuze uthole izixazululo ezingcono kakhulu zokuthuthukisa ezihambisana nezidingo ezithile zokukhiqiza.

Isikhathi sokuthumela: Sep-02-2025