I-Conical Twin Screw Barrels isiyinto ebaluleke kakhulu ekukhiqizeni kwesimanje. Umklamo wabo oyingqayizivele uqinisekisa ukuphathwa kwempahla enembile, ukuxuba okufanayo, nokuncibilika okuphumelelayo, okubalulekile ekukhiqizeni imikhiqizo yekhwalithi ephezulu. Emashumini eminyaka adlule, amadizayini ngezikulufu athuthuke kakhulu, ngezilinganiso zobude ukuya kububanzi (L/D) ezikhuphuka zisuka ku-20:1 ziye ku-40:1, okuvumela ukusebenza okungcono. Ubuchwepheshe obuthuthukile, obufana nama-in-line PAT probes asebenzisa i-Raman spectroscopy, buthuthukisa futhi ukuqina kokukhiqiza ngokuqapha ikhwalithi yezinto ezibonakalayo ngesikhathi sangempela. Lezi zindlela ezintsha zimiI-Conical and Parallel Twin Screw Barrels, kanyeI-Tapered Twin Screw Barrel kanye ne-Screw, njengezingxenye ezibalulekile kuzinqubo zokubumba ze-extrusion kanye nomjovo. Ngaphezu kwalokho, i-I-Single Parallel Conical Twin Screw Barrelinikeza izinzuzo ezihlukile zezinhlelo zokusebenza ezithile, ngokuqhubekayo ukwandisa ukuguquguquka kwala mathuluzi okukhiqiza abalulekile.

Amathrendi akamuva kuma-Conical Twin Screw Barrels

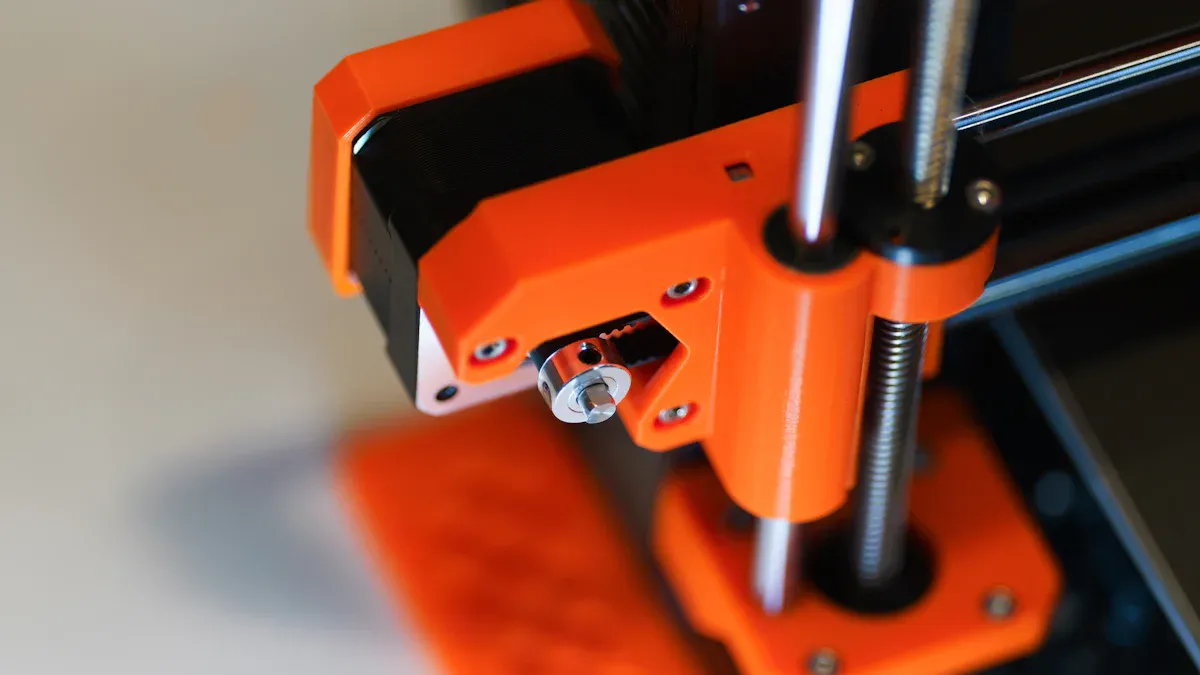

Intuthuko ku-Barrel Design

Imiklamo yesimanje yemiphongolo ishintsha ukusebenza kwemiphongolo yesikulufu yamawele angama-conical. Onjiniyela basebenzisa izindlela zokukhiqiza ezingeziwe kanye nezindlela zokusakaza ezinembayo ukuze bakhe ukucushwa kwesikulufu okwenziwe ngokwezifiso kakhulu. Le ntuthuko inika amandla ukwenziwa kwe-prototyping ngokushesha kanye nemijikelezo yokuthuthukisa umkhiqizo esheshayo.

Qaphela: Ijometri yomgqomo othuthukisiwe ithuthukisa ukugeleza kwezinto, iqinisekisa ukuncibilika okufanayo nokuxuba.

Umkhakha we-plastic extrusion uzuze kakhulu kulezi zindlela ezintsha. Isibonelo, ama-extruder e-conEX NG manje athola imiphumela esukela ku-80 kuye ku-550 lb/hr kumaphrofayili futhi kufika ku-1000 lb/hr kumapayipi. Ukwengeza, ukushiswa kokushisa okuphelele kwemiphongolo kunciphisa ukulahleka kwemisebe, okunomthelela ekusebenzeni kahle kwamandla.

| Isu | Umthelela Ekusebenzeni Kahle |

|---|---|

| Ukuthuthukisa Amasistimu Wezimoto NeDrayivu | Inciphisa ukumosheka kwamandla kakhulu, yonga u-10-15% ngokukhipha ama-gearbox angasebenzi kahle. |

| Amasu Okushisisa Athuthukisiwe | Amasistimu wokungenisa athuthukisiwe anciphisa amandla okushisa aphelele ngo-10%. |

| Idizayini Yesistimu Yokupholisa Elungiselelwe | Yehlisa izikhathi zomjikelezo futhi yehlise ukusetshenziswa kwamandla ngokunciphisa ukupholisa ngokweqile. |

| Ukubuyisela Ukushisa Kwemfucuza | Ingakwazi ukubuyisela amandla afika ku-15% alahlekile, inciphise izindleko zokusebenza. |

Izinto Ezisebenza Kakhulu Nokuqina

Ukuqina kwe-conical twin screw barrel sekufinyelele ukuphakama okusha ngenxa yokusetshenziswaizinto zokusebenza eziphezulu. Abakhiqizi manje basebenzisa ama-alloys athuthukile anikeza amandla akhethekile okusebenza, ukumelana ne-torque, nokumelana nokuguga. Lezi zinto ziqinisekisa ukuthi imiphongolo ingakwazi ukumelana namazinga okushisa aphezulu kanye nezingcindezi ngesikhathi sokusebenza.

- Amandla Emishini: Ibalulekile ekumelaneni nokungqubuzana nokugqwala.

- Ukumelana ne-Torque: Ibalulekile ekucutshungulweni kwezinto eziqhubekayo ngaphansi kwezimo zesivinini esikhulu.

- Ukumelana ne-Deformation: Igcina ukusebenza ngaphansi kwezimo ezimbi kakhulu, iqinisekisa i-plasticization ephumelelayo.

Ukuthuthukiswa kwalezi zinto kuphinde kwehlise izindleko zokulungisa kubasebenzisi, njengoba imiphongolo manje isinokuphila isikhathi eside. Ubambiswano lwamasu phakathi kwabakhiqizi nezikhungo zocwaningo lusheshisa ukwakhiwa kwezixazululo ezihlala isikhathi eside nakakhulu.

Ukusebenza kahle kwamandla kanye nokuthuthukisa izindleko

Ukusebenza kahle kwamandla sekuphenduke insika yobuchwepheshe besimanje obuyindilinga obungamawele esikulufa. Abakhiqizi bahlanganisa ukungabaza kanye nama-synchronous motors, okuye kwabikwa ukuthi konga kufika ku-20% ekusetshenzisweni kwamandla. Amasistimu wokushisisa athuthukisiwe nawokupholisa athuthukisa ukusebenza kahle ngokunciphisa izikhathi zomjikelezo kanye nokunciphisa ukumosheka kwamandla.

- Ukwenyuka kwamazinga epulasitiki, ukusuka ku-104 g/s kuya ku-120 g/s, kubonwe.

- Izikhathi zokutakula zehlile ukusuka kumasekhondi angu-18 ukuya kumasekhondi angu-9 nje.

- Izikhathi zomjikelezo sezizonke zehlisiwe ukusuka kumasekhondi angama-30 kuye kumasekhondi ayi-15.

Lokhu kuthuthukiswa akukona nje kuphela ukunciphisa izindleko zokusebenza kodwa futhi kuhambisana nesidingo esikhulayo sezinqubo ezisimeme zokukhiqiza.

Ukwenza ngendlela oyifisayo kwezinhlelo zokusebenza eziqondene nemboni

Isidingo semiphongolo yesikulufu enziwe ngokwezifiso siyakhuphuka ezimbonini ezahlukahlukene. Izixazululo eziklanyelwe manje seziyatholakala ukuze zihlangabezane nezidingo ezihlukile zemikhakha efana nemithi, amapulasitiki, nokuguqulwa kwe-polymer.

| Isici/Inzuzo | Incazelo |

|---|---|

| Intelligent Monitoring Technology | Ithuthukisa ukusebenza ngokufaka kabusha izinkinobho zokunyathelisa ezikhona, ukubhekana nokungasebenzi kahle. |

| Amasistimu Okulawula Okuhlakaniphile | Inika amandla ukulungiswa okunembile kwezinga lokushisa, ukucindezela, nesivinini sesikulufu ukuze uthole imiphumela emihle. |

| Ukusebenza Kwamandla | Ihlanganisa izinhlelo zokushayela ezonga amandla, ukunciphisa izindleko zokusebenza kanye nomthelela emvelweni. |

| I-Optimized Screw Geometry | Yehlisa ukulahleka kwamandla, iqinisekise ukuguqulwa okusebenzayo komshini ukuya kumandla ashisayo. |

| Ukuzivumelanisa nezimo | Ivumela ukulungiswa kobubanzi bemiphongolo ukuze kukhuliswe amanani okukhiphayo kanye nekhwalithi yokuncibilika. |

| Ikhwalithi Yokukhipha Okungaguquki | Iqinisekisa umbala ofanayo kanye nokuzinza kwe-dimensional ngesivinini esilawulwayo sesikulufa netorque. |

I-Feed Screw Barrel Market ibhekene nokukhula okuphawulekayo ngenxa yalezi ntuthuko. Imishini esebenza kahle kakhulu kanye nezingxenye ezinembayo sezibalulekile ekucubunguleni izinto eziyinkimbinkimbi, okuqhubekisela phambili isidingo sezixazululo ezenziwe ngokwezifiso.

Okusungulwe Okubalulekile ku-Conical Twin Screw Barrel Technology

Ukwenza idijithali nezilawuli ezihlakaniphile

Ukwenza idijithali kuguqule ukusebenza komgqomo wesikulufu esiphindwe kabili, okuvumela abakhiqizi ukuthi bafinyelele amazinga angakaze abonwe okunemba nokusebenza kahle. Amanethiwekhi ezinzwa athuthukile manje aqapha amapharamitha abalulekile njengezinga lokuphuma, ukukhiqizwa kwetorque, nokuguga kwezingxenye ngesikhathi sangempela. Lezi zinzwa zihlinzeka ngemininingwane engenzeka, evumela opharetha ukuthi benze izinguquko ngokushesha ukuze bathuthukise ukusebenza.

Amasistimu okulawula ahlakaniphile, anikwa amandla ubuchwepheshe obuwele bedijithali, alingisa yonke inqubo yokukhiqiza. Lokhu kusungula kwenza abakhiqizi bakwazi ukubikezela izingcindezi zokusebenza, ukukhomba izingqinamba, futhi banciphise ukumisa. Isibonelo, izinkampani ezifana ne-ExxonMobil zenze ngempumelelo amawele edijithali ukuthuthukisa ukuhlela ukukhiqiza nokuthuthukisa ukwenza izinqumo. Izibalo eziqagelayo zithuthukisa futhi lezi zinhlelo, zinike amandla amashejuli okulungisa angcono futhi zinciphise isikhathi sokuphumula.

Izinzuzo ezibalulekile zedijithali zifaka:

- Izibalo zesikhathi sangempelaukulungisa okusebenzayo.

- Ukugcinwa okusekelwe esimweniukwandisa ubude besikhathi semishini.

- Ukuhlelwa kokusebenza okuthuthukisiwengokusebenzisa imininingwane ebikezelwayo.

Le ntuthuko iqinisekisa ukuthi i-conical twin screw barrel ihlala iyisisekelo sokukhiqiza kwesimanje, iletha imiphumela engashintshi kuzo zonke izinhlelo zokusebenza ezahlukahlukene.

Amasistimu Wokulungisa Okubikezelwayo

Izinhlelo zokulungisa izinto ezibikezelayo ziye zashintsha indlela abakhiqizi abaphatha ngayo imishini yabo. Ngokusebenzisa izinzwa ezigcwele zonke kanye nezibalo zesikhathi sangempela, lawa masistimu aqapha amapharamitha ahlukahlukene ukuze alindele izinkinga ezingaba khona ngaphambi kokuba zande. Le ndlela inciphisa isikhathi sokuphumula esingahleliwe futhi inciphisa kakhulu izindleko zokulungisa.

Ucwaningo lwezimboni lugqamisa ukusebenza kahle kokuqagela ukunakekelwa:

| Imboni/Inkampani | Incazelo Yomphumela | Ukwehliswa Kwesikhathi Sokuphumula/Izindleko |

|---|---|---|

| I-Fleet Operator | Ukwehla ngo-25% kokuqhekeka okuholela ekuletheni ngokushesha kanye nezindleko zokulungisa eziphansi. | 25% yehla ekuqhekekeni |

| Ifemu Kawoyela Negesi | Isindise izigidi ngokulindela izinkinga zemishini, esikhundleni sokulungisa izimo eziphuthumayo. | Ukonga izindleko okubalulekile |

| I-Power Plant Operator | Nciphisa ukucisha okungahleliwe ngo-30%, uthuthukise isikhathi sokugcina sempahla. | Ukunciphisa ngo-30% kokucisha |

| I-General Motors (GM) | Kwehliswe isikhathi sokuphumula esingalindelekile ngo-15%, konga u-$20 wezigidi ngonyaka. | Ukwehliswa kwe-15% ngesikhathi sokuphumula |

Emiphongolweni yesikulufu esiyi-conical twin, ukunakekelwa okubikezelwayo kuqinisekisa ukusebenza okuphezulu ngokubhekana nokuguga nokudabuka. Lolu hlelo alugcini nje ngokunweba impilo yezinto zokusebenza kodwa futhi luthuthukisa ukukhiqiza jikelele.

Izici ezigxile ekuzinzeni

Ukuzinza sekuyinto okugxilwe kuyo okubalulekile ekuthuthukisweni kobuchwepheshe bemiphongolo yamawele angamawele. Abakhiqizi basebenzisa izinto zokwakha ezinobungani nemvelo kanye namasu okunciphisa udoti ukuze kuhlangatshezwane nezidingo zokulawula kanye nokulindelwe ngamakhasimende. Lezi zindlela ezintsha zihambisana nokuphushwa komhlaba jikelele kwezinqubo zokukhiqiza okuluhlaza.

Ukuthuthuka kobuchwepheshe bokumboza kanye nokwakheka kwengxubevange kuphinde kwathuthukisa ukusimama kwale miphongolo. Izembatho ezithuthukisiwe zinciphisa ukungqubuzana nokuguga, zehlisa ukusetshenziswa kwamandla ngesikhathi sokusebenza. Ukwengeza, amasistimu okubuyisela ukushisa okulahlwayo abuyisela amandla afika ku-15% alahlekile, okunciphisa kakhulu izindleko zokusebenza.

Izici ezibalulekile zokusimama zihlanganisa:

- Izinto zokwakha ezinobunganeezinciphisa umthelela kwezemvelo.

- Imiklamo eyonga amandlaukunciphisa ukusetshenziswa kwezinsiza.

- Amasu okunciphisa imfucuzangezinqubo zokukhiqiza ezihlanzekile.

Lezi zici ziqinisekisa ukuthi i-conical twin screw barrel ihlala iyisixazululo esisebenzayo sezimboni ezihlose ukulinganisa ukusebenza nomthwalo wemfanelo wendawo.

Imiklamo ye-Modular kanye Nokuguquguquka

Imiklamo ye-modular yethule izinga elisha lokuguquguquka kumasistimu we-conical twin screw barrel. Le miklamo ivumela abakhiqizi ukuthi benze imiphongolo nezikulufu ngokwezifiso zezinhlelo zokusebenza ezithile, okuqinisekisa ukusebenza okuhle kuzo zonke izimboni ezahlukahlukene. Ukukhiqiza okungeziwe kanye nezindlela zokusakaza ezinembayo ziye zathuthukisa lokhu kuvumelana nezimo, zivumela ukwenziwa kwe-prototyping ngokushesha kanye nesikhathi esisheshayo sokuthengisa imikhiqizo emisha.

Izicelo ezisafufusa ekwenziweni kwemithi kanye nokuguqulwa kwe-polymer kuqhubekisele phambili isidingo sokulawula okuqinile phezu kwemingcele yokusebenza. Imiklamo ye-modular ibhekana nalezi zidingo ngokuvumela ukulungiswa kobubanzi bemiphongolo, ukumiswa kwezikulufu, nezinhlelo zokushisisa. Lokhu kuzivumelanisa nezimo kuqinisekisa ikhwalithi yokuphuma engaguquki kanye nokusebenza kahle okuthuthukisiwe.

| Imethrikhi | Inani |

|---|---|

| I-CAGR elindelwe | 5% |

| Ubude besikhathi | Iminyaka emihlanu ezayo |

| Izici Eziyinhloko | Intuthuko ezinqubweni zokukhiqiza, ukwandiswa kwemikhakha yezimboni, ukusetshenziswa kwama-alloys athuthukile, amasu okukhiqiza anembayo |

Indlela ye-modular ayigcini nje ngokuthuthukisa ukuguquguquka kwemiphongolo yamawele angamawele kodwa futhi iyibeka njengesixazululo sobufakazi besikhathi esizayo sokuvela kwezidingo zezimboni.

I-Industrial Impact ye-Conical Twin Screw Barrel Advancements

Ukuphumelela Kwezokukhiqiza Okuthuthukisiwe

Intuthuko kuama-conical twin screw imiphongolozenze ngcono kakhulu ukusebenza kahle kwezokukhiqiza. Imiklamo yesimanje inika amandla ukuhlanganisa okunembile ngokucutshungulwa kwe-shear ephezulu ngokukhuphuka okuncane. Lokhu kuqinisekisa ukuxuba okufanayo futhi kunciphisa isikhathi sokucubungula. Ukwengeza, ukuguquguquka kwale miphongolo kuvumela abakhiqizi ukuthi baphathe uhla olubanzi lwezinto zokwakha, kufaka phakathi amapulasitiki okunzima ukuwasebenzisa kabusha.

| I-Metric/Cost Aspect | Incazelo |

|---|---|

| Ukuxuba Okuthuthukisiwe Nokucubungula | Ama-extruder ama-twin screw ahlinzeka ngokushear okuphezulu ngokukhuphuka okuncane ukuze kuhlanganiswe okunembile. |

| Ukuhlukahluka Ekucubunguleni Okubalulekile | Iyakwazi ukucubungula uhla olubanzi lwezinto zokwakha, kufaka phakathi amapulasitiki okunzima ukuwasebenzisa kabusha. |

| Ukwehliswa Kwezindleko | Yehlisa izindleko ezihambisana nokulahlwa kukadoti kanye nokuthengwa kwezinto ezingavuthiwe. |

| Ikhwalithi Yomkhiqizo Ethuthukisiwe | Ukwelulwa okuthuthukisiwe emananini ekhefu amapulasitiki angahlungiwe kabusha, akhulisa ukuqina. |

Lokhu kuthuthukiswa kwenza kube lula izinqubo zokukhiqiza, ukunciphisa isikhathi sokuphumula, futhi kuthuthukise ukusebenza kahle sekukonke.

Ukwehliswa Kwezindleko kanye Nokunciphisa Imfucuza

Ukuhlanganiswa kobuchwepheshe be-conical twin screw barrel obuthuthukisiwe kuholele ekuphawulekeniukonga izindleko. Ngokulungiselela ukusetshenziswa kwezinto ezibonakalayo kanye nokunciphisa ukumosha, abakhiqizi bangehlisa izindleko ezihambisana nokuthengwa nokulahlwa kwezinto ezingavuthiwe. Amasistimu okubuyisa ukushisa okulahlwayo aphinde abe negalelo ekwehliseni izindleko ngokufuna kabusha afinyelela ku-15% wamandla alahlekile.

Ithiphu: Izinkampani ezisebenzisa lobu buchwepheshe zivame ukubika ukwehla okukhulu kwezindleko zokusebenza, okuzenza zibe utshalomali olubalulekile lokusimama kwesikhathi eside.

Ukunwetshwa kuzinhlelo zokusebenza ezihlukene

Ukuvumelana nezimo kwe-conical twin screw barrel kuvule iminyango yezinhlelo zokusebenza ezihlukene zezimboni. Le miphongolo manje isisetshenziswa kabanzi emikhakheni efana nemithi, amapulasitiki, kanye nokuguqulwa kwe-polymer. Ikhono labo lokucubungula izinto eziyinkimbinkimbi ngokunemba kubenza babaluleke kakhulu ekukhiqizeni imikhiqizo yekhwalithi ephezulu kuzo zonke izimboni ezihlukahlukene.

Izinhlelo zokusebenza ezisafufusa zihlanganisa ukukhiqizwa kwama-polymer ebanga lezokwelapha nezinhlanganisela ezithuthukile, lapho ukulawula okuqinile phezu kwemingcele yokusebenza kubalulekile. Lokhu kuguquguquka kuqinisekisa ukuthi ama-conical twin screw barrel ahlala efanelekile ezimakethe ezithuthukayo.

Ikhwalithi Yomkhiqizo Ethuthukisiwe kanye Nokungaguquguquki

Imiklamo ethuthukisiwe yemiphongolo iye yashintsha izinga lomkhiqizo nokuvumelana. Uchungechunge lwe-JT i-screw barrel eyodwa, ngokwesibonelo, yehlisa izimbobo ezikhonjiwe emikhiqizweni eqediwe ngo-90%, iqinisekisa ikhwalithi ephezulu yokuncibilika. Lokhu kuthuthukisa amandla efilimu nokunwebeka, okwenza imikhiqizo ihlale isikhathi eside futhi ithembekile.

- Idizayini iqinisekisa okuqukethwe komswakamo okungaguquki kwembudumbudu elungile.

- Amathuluzi okuqapha esikhathi sangempela, njenge-NIR ne-Raman spectroscopy, anikeza impendulo esheshayo ngezibaluli zekhwalithi.

- Ukufana kwenhlanganisela okuthuthukisiwe nokusabalalisa usayizi wegranule kuthuthukisa ukusebenza komkhiqizo kukonke.

| Kala | Incazelo |

|---|---|

| Okuqukethwe Umswakama | Iqashwe ukuze kuqinisekiswe izimo ezifanele ze-granulation. |

| I-API Content Uniformity | Ihlolwe ukuze kugcinwe ukusatshalaliswa kwesithako semithi okungaguquki. |

| Hlanganisa i-Uniformity | Ihlolwe ukuze kuqinisekiswe i-homogeneity engxubeni ngaphambi kwe-granulation. |

| Ukusabalalisa Usayizi weGranule | Izingxenye ze-D10, i-D50, ne-D90 ziqashwe ukuze kuhlolwe ukuhluka kosayizi wezinhlayiyana. |

| Isimo Esiqinile Sesithako Esisebenzayo | Kuqinisekisiwe ukugcina ukusebenza kahle kwesithako esisebenzayo kuyo yonke inqubo. |

Le ntuthuko igqamisa umthelela oguquguqukayo wemiphongolo yesikulufu ephindwe kabili ezinqubweni zokukhiqiza, iqinisekisa ikhwalithi yokuphuma engaguquki kanye nokuhlangabezana namazinga emboni aqinile.

Izinselelo Namathuba Emakethe Yemigqomo Ye-Conical Twin Screw

Ukunqoba Izindleko Eziphezulu Zokuqala

Izindleko zokuqala eziphakeme ngokuvamile zivimbela abakhiqizi ekuthatheni izinyathelo eziphambiliama-conical twin screw imiphongolo. Kodwa-ke, lezi zindleko zingaxazululwa ngezinzuzo zesikhathi eside ezifana nezindleko zokunakekela ezincishisiwe kanye nokusebenza kahle okuthuthukisiwe. Izinkampani ziya ngokuya zinikeza izinketho zezimali nezinhlelo zokuqashisa ukwenza lobu buchwepheshe bufinyeleleke kalula. Ukwengeza, intuthuko ezinqubweni zokukhiqiza, njengokukhiqiza okungeziwe, yehlise izindleko zokukhiqiza, okwenza le miphongolo ithengeke kakhulu.

Ithiphu: Ukutshala imali emiphongolweni yekhwalithi ephezulu kunciphisa isikhathi sokuphumula futhi kuthuthukisa ukukhiqiza, okuholela ekongeni kwezindleko ezibalulekile ngokuhamba kwesikhathi.

Ukubhekana Nokushoda Kwabasebenzi Abanekhono

Imboni ibhekene nokushoda kwabasebenzi abanamakhono abakwazi ukusebenza nokuyinakekelaimishini ethuthukisiwe. Ukubhekana nalokhu, abakhiqizi basebenzisa izinhlelo zokuqeqesha futhi banikeze izitifiketi kubasebenzi abathuthukisa amakhono. Okuzenzakalelayo kanye nezinhlelo zokulawula ezihlakaniphile ziphinde zehlise ukuncika ekungeneleleni ngezandla, okwenza imisebenzi ibe lula kubasebenzi abanolwazi oluncane. Lezi zinhlelo ziqinisekisa ukuthi abasebenzi bahlala behlomele ukuphatha ubuchwepheshe obuthuthukayo.

Amathuba Okukhula Ezimakethe Ezisafufusa

Izimakethe ezisafufusa zinikeza amathuba abalulekile okukhula emiphongolweni yamawele angamawele. Izinkampani ziqondise izifunda ezinesidingo esikhulu nokuncintisana okuphansi ukuze zandise isabelo sazo semakethe.

- Izimakethe ezikhula ngokushesha zamaphampu ngezikulufu ezingamawele zibonisa amandla afanayo emiphongolo yesikulufu yamawele ayikhonical.

- Ukuhlunga idatha yokungenisa ngezwe kanye nezinga lokukhula kusiza ukukhomba izifunda ezithembisayo.

- Amasu agxile ekungeneni ezimakethe ezinesidingo esikhulu sobuchwepheshe bokukhipha umjovo nokubumba umjovo.

Le mizamo ibeka abakhiqizi ukuthi basebenzise amathuba angakasetshenziswa kwezomnotho ezisathuthuka.

Ukusebenzisana kanye Namathuba Okusungula

Ukusebenzisana phakathi kwabakhiqizi nabahlinzeki bezobuchwepheshe kushayela ukuqamba okusha embonini ye-conical twin screw barrel. Amaphrojekthi okuhlanganisa aphumelelayo abonisa amandla okonga izindleko kanye nokwenza ngcono ukusebenza kahle.

| Inkampani | Impumelelo Metrics |

|---|---|

| Izinkampani Eziphezulu | Ilondolozwe ngaphezulu kuka-$5 umphongolo ngamunye olingana nowoyela ngokuhlola nokubhola okufakwe ubuchwepheshe. |

| Izinkampani Ezihamba Phansi | Ilondolozwe ngaphezu kuka-$1 ngomphongolo kuyilapho ithuthukisa ukutholakala kwempahla kanye nenzuzo. |

| I-Woodside Energy | Kwehliswe izindleko zokusebenza ngo-30% kusetshenziswa i-AI kanye ne-automation. |

| I-Kuwait Oil Company | Izinhloso zokukhiqiza ezithuthukisiwe ngezinqubo zokuzenzakalela nokugeleza komsebenzi. |

| I-Chevron | Ukuphathwa kwephothifoliyo okuthuthukisiwe ukuze kulethwe imininingwane esebenzisekayo ukuze kube nokusebenzisana okungcono. |

Lokhu kubambisana kugqamisa umthelela oguquguqukayo wobungcweti nezinsiza ezabiwe, okuvula indlela yentuthuko yesikhathi esizayo embonini.

Intuthuko kubuchwepheshe be-conical twin screw barrel imise kabusha izinqubo zokukhiqiza. Ukwakhiwa okusha, izinto zokwakha, kanye nokwenza idijithali kuqinisekisa ukusebenza kahle nokusimama.

Le miphongolo iqhuba ukunemba nokonga amandla, okuyenza ibaluleke kakhulu ezimbonini zesimanje. Ikusasa labo lilele ekuvumeleni ukukhiqizwa okuluhlaza ngenkathi kuhlangatshezwana nezidingo ezihlukene zohlelo lokusebenza.

Abakhiqizi bayaqhubeka nokuhlola amathuba amasha, baqinisekisa ukukhula kwemboni yesikhathi eside.

FAQ

Yiziphi izimboni ezizuza kakhulu emiphongolweni eyi-conical twin screw?

Imiphongolo eyi-Conical twin screw isetshenziswa kakhulu kumapulasitiki, ekhemisi, nasezimbonini zokuguqula i-polymer. Ukuvumelana nezimo kuqinisekisa ukusebenza kahle kwezinto eziyinkimbinkimbi kuzo zonke izinhlelo zokusebenza ezihlukahlukene.

Imiklamo ye-modular ithuthukisa kanjani izinqubo zokukhiqiza?

Imiklamo ye-modular ivumela abakhiqizi ukuthi benze imiphongolo nezikulufu ngezifiso ngezidingo ezithile. Lokhu kuvumelana nezimo kuthuthukisa ukusebenza kahle, kunciphisa isikhathi sokuphumula, futhi kuqinisekisa ikhwalithi yomkhiqizo engaguquki.

Ingabe ama-conical twin screw barrel ahambisana nemvelo?

Yebo, imiklamo yesimanje ihlanganisa izinto ezivumelana nemvelo, amasistimu awonga amandla, namasu okunciphisa udoti. Lezi zici zihambisana nemigomo yokusimama komhlaba wonke futhi zinciphise umthelela wendawo.

Isikhathi sokuthumela: Jun-06-2025