I-scrusion yesikulufu esisodwa isebenzisa isikulufu esisodwa esizungezayo, kuyilapho i-twin screw extrusion incike kuzikulufu ezimbili ezihlanganayo ukuze kuhlanganiswe okuthuthukisiwe. Lo mehluko uthinta ikhwalithi yomkhiqizo kanye nokulawula inqubo. Ukuze kube lula, ukukhiqizwa kwevolumu ephezulu, aI-Single Plastic Screw Barrelifanele izidingo eziningi.I-Twin Screw Extruder BarrelsfuthiIzikulufo Ezimbili Zezikhiqizo Zepulasitikiuphumelele ekuxubeni okuyinkimbinkimbi.

Kuchazwa Ukukhishwa Kwesikulufa Esisodwa

Indlela I-Single Screw Extrusion Esebenza Ngayo

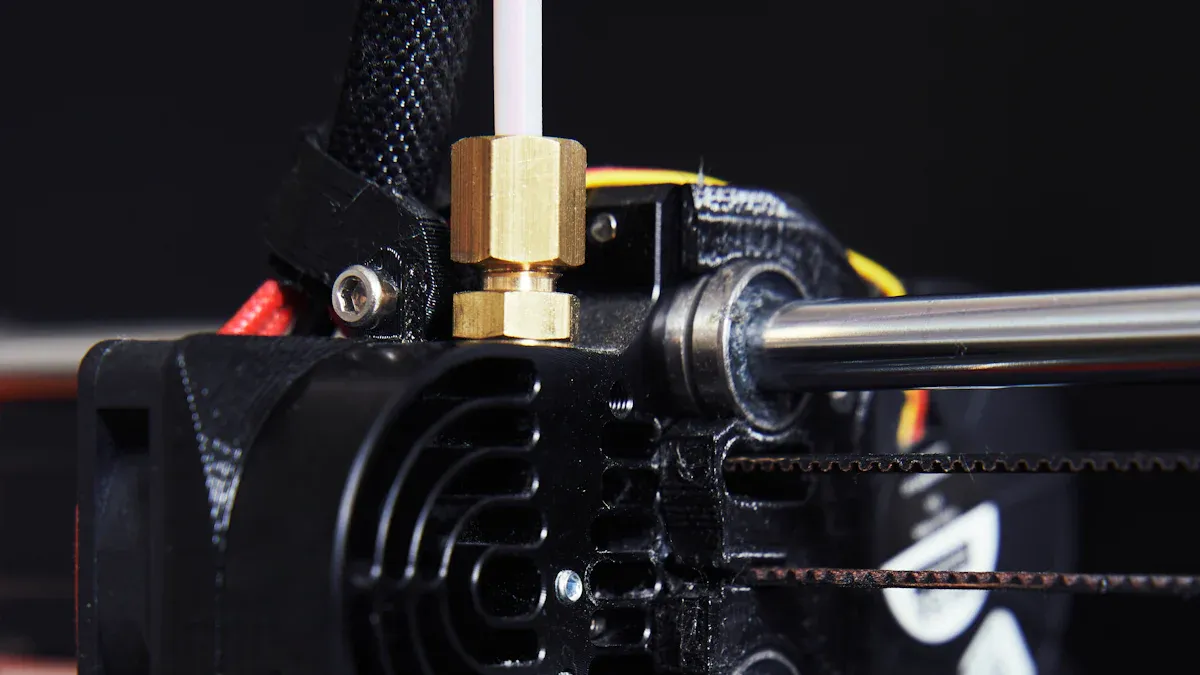

I-scrusion yesikulufu esisodwa isebenzisa isikulufu esisodwa esizungezayo ngaphakathi kombhobho oshisayo. Isikulufu siyisa ipulasitiki eluhlaza noma impahla yerabha phambili, lapho ukungqubuzana nokushisa kuncibilikisa khona. Impahla encibilikisiwe idlula idayisi ukuze yakhe umumo oqhubekayo. Ama-opharetha alawula amapharamitha enqubo yokhiye afana nezinga lokushisa lomgqomo (ngokuvamile li-160–180 °C), isivinini sesikulufu, nezinga lokushisa lokufa. Isivinini seyunithi yokuthatha kanye nezinga lokushisa lethangi lamanzi kusiza ukulawula ububanzi nokupholisa komkhiqizo wokugcina. Isikulufu siyasebenzaimisebenzi emithathu eyinhloko: ukudlulisa, ukuncibilika, nokuxuba. Idizayini yomgqomoizici ezifana ne-hard tempering kanye ne-chrome plating kunciphisa ukungqubuzana nokunamathela, okuqinisekisa ukusebenza kahle.

Izinzuzo ze-Single Screw Extrusion

Abakhiqizi bayakhethaisikulufa esisodwa extrusionngobulula bayo kanye nokusebenza kahle kwezindleko. Idizayini ivumela ukusebenza nokugcinwa kalula. Ukutshalwa kwezimali okuphansi kokuqala kanye nezindleko zokusebenza kukwenza kukhange amabhizinisi amaningi.Ukusebenza kahle kwamandlakuyagqama, njengoba uhlelo lisebenzisa ukufudumeza okulungiselelwe kanye nezingxenye ezihambayo ezimbalwa. Ama-opharetha angafinyelela ikhwalithi yomkhiqizo engaguquki ngokulungisa izinga lokushisa, ukucindezela, nesivinini sesikulufu. Lolu hlelo lusingatha inhlobonhlobo yezinto ezingavuthiwe, okulwenza lusebenziseke ngezindlela eziningi izidingo zokukhiqiza ezahlukene.

Ithiphu: Ukunakekelwa okuvamile kanye nokuqapha amandla ngesikhathi sangempela kungathuthukisa ukusebenza kahle nekhwalithi yomkhiqizo.

Imikhawulo Yesikulufa Esisodwa Extrusion

I-scrusion yesikulufu esisodwa ibhekene nezinselelo ezithile. Okukhiphayo kungase kungazinzi ngesivinini esikhulu sezikulufu, kunciphise amazinga okukhiqiza. Ukugcina izinga lokushisa elincibilikayo kanye ne-homogeneity yomkhiqizo kungaba nzima, ikakhulukazi ngezinto eziyinkimbinkimbi. Inqubo ingase ibe nzima nokuxuba okuthuthukile noma ukwakheka okudinga ukulawula okunembayo. Ukuziphatha kokuphakelayo kanye nokuphumayo nakho kuncike kakhulu ekwakhiweni kwesikulufa kanye nejiyomethri yokuvula okuphakelayo.

Izicelo Ezijwayelekile Ze-Single Screw Extrusion

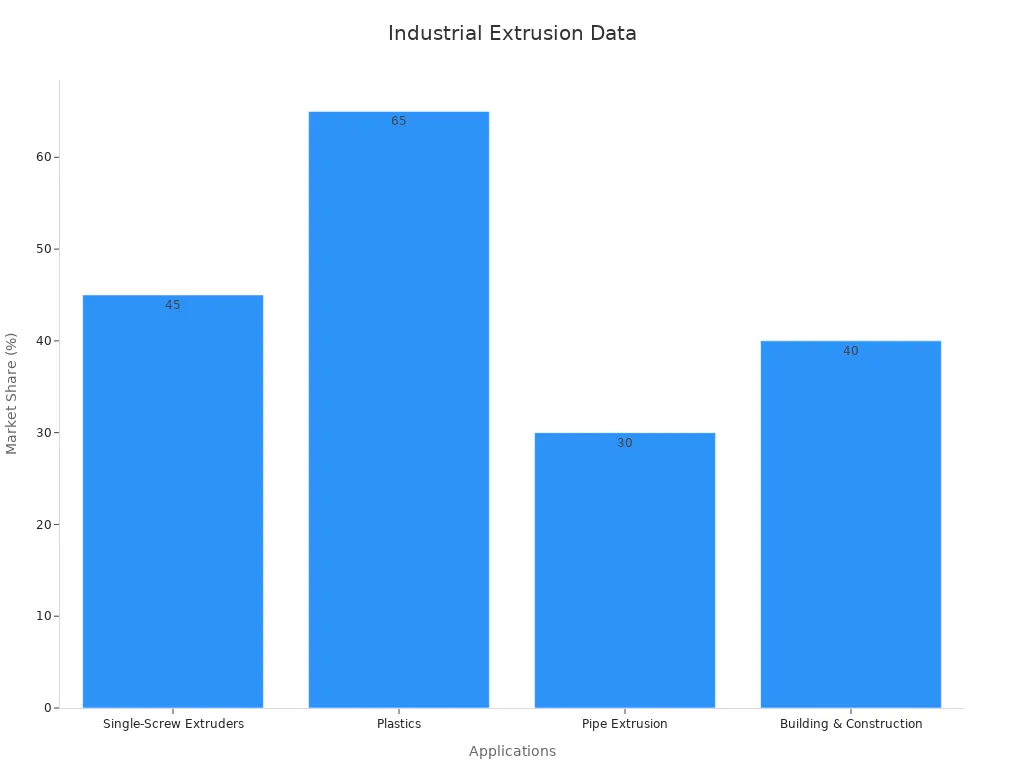

I-screw extrusion eyodwa ithola ukusetshenziswa ezimbonini eziningi. Ukupakishwa kuhola imakethe, ngesabelo esingaba ngu-60%, ikhiqiza amafilimu namashidi asuka kuma-polymer afana ne-PE, PP, ne-PVC. Umkhakha wezokwakha uwusebenzisela amapayipi namaphrofayili, kuyilapho abakhiqizi bezimoto bethembele kuwo ukuze uthole izingxenye zangaphakathi nezangaphandle. Izimboni zezokwelapha, zezimpahla zabathengi, neze-elekthronikhi nazo ziyazuza kulobu buchwepheshe.

| Uhlobo Lwemodeli | Isikulufa Ububanzi (mm) | L:D Isilinganiso | Amandla Emotor (kW) | Umthamo Wokukhipha (kg/hr) | Amanothi Ngempumelelo Namazinga |

|---|---|---|---|---|---|

| Isikulufu Esisodwa Esisebenza Kakhulu | 60 - 120 | 38:1 | 110 – 315 | 465 - 1300 | 20-30% izinga eliphezulu; I-Siemens AC motors, i-CE-certified |

| Normal Standard Single Screw | 60 - 120 | 33:1 | 55 – 315 | 150 - 900 | Izingxenye zekhwalithi ezijwayelekile |

Ukubuka konke kwe-Twin Screw Extrusion

Isebenza kanjani i-Twin Screw Extrusion

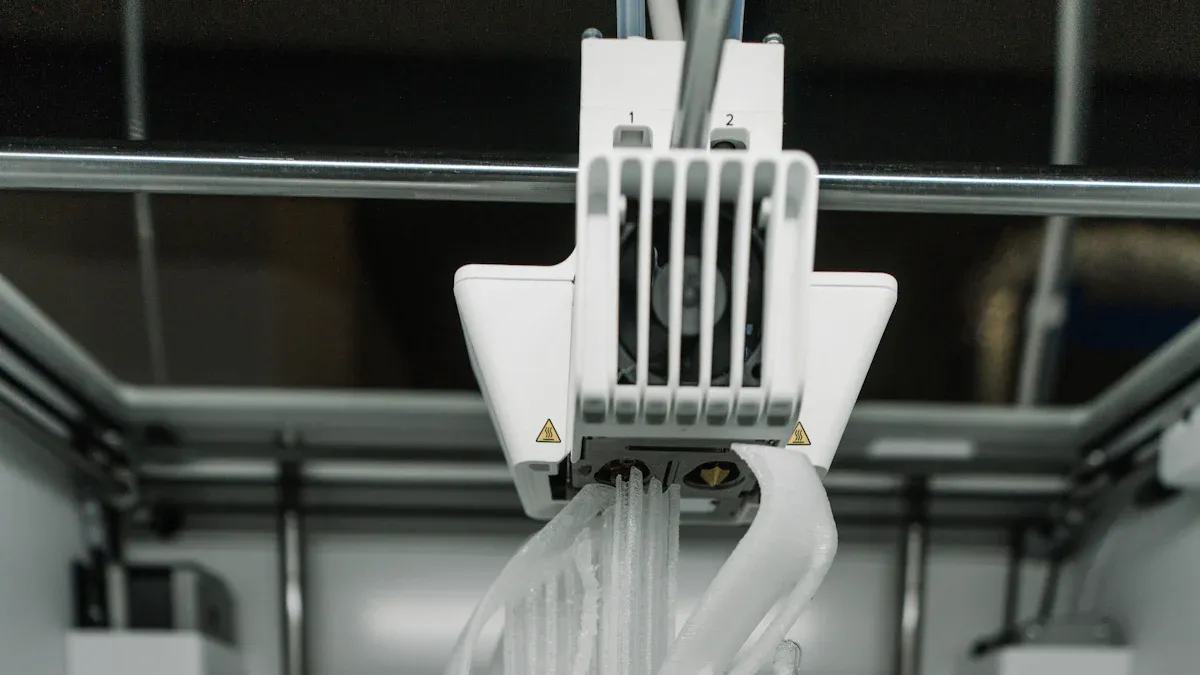

I-twin screw extrusionisebenzisa izikulufu ezimbili ezihlanganayo ezizungeza ngaphakathi kombhobho oshisayo. Ama-opharetha afaka izinto zokusetshenziswa njengama-pellets noma izimpushana ku-hopper. Izikulufu zihambisa impahla phambili, ziyicindezele futhi ziyixove. Ukushisa okuvela emgqonyeni kanye nokungqubuzana okuvela kuzikulufu kuncibilikise into. Izinto eziyisikulufa eziyisipesheli ziyaxuba futhi zincibilikise i-homogenize, iqinisekisa ngisho nokusatshalaliswa kwezithasiselo. Indwangu encibilikisiwe ibe isidlula edayini ukuze kwakhe umkhiqizo wokugcina. Imiphongolo ye-modular enezindawo zokufudumeza nezokupholisa ivumela ukulawula izinga lokushisa okunembile. Izindawo zokungenisa umoya zisusa umoya nokuguquguquka, kuthuthukisa ikhwalithi yomkhiqizo.

Amandla e-Twin Screw Extrusion

I-Twin screw extrusion inikeza izinzuzo eziningana:

- Ukuxuba okuphezulu kanye ne-homogenization ngenxa yezikulufu ezihlanganayo.

- Amandla aphezulu okugundathuthukisa ukuhlanganisa kanye nokufana komkhiqizo.

- Idizayini ye-modular ivumela ukulungiswa okulula kwezinto ezahlukahlukene.

- Ukulawulwa kwezinga lokushisa okuthuthukisiwe kunciphisa ukuwohloka kokushisa.

- Ukusebenza okuphezulu nokukhiqiza kusekela ukukhiqizwa kwenani elikhulu.

- Ukucushwa kwesikulufu esivumelana nezimo kuthuthukisa ukucutshungulwa kwama-polymer ahlukahlukene.

- Ukulawula inqubo engcono ngokulungiswa okuzimele kwejubane lesikulufa nezinga lokushisa.

- Impilo ende yesisetshenziswa njengomthwalo yabelwa phakathi kwezikulufu ezimbili.

| Isici Sobuchwepheshe | Incazelo |

|---|---|

| Ukuxuba Okuphezulu & I-Homogenization | Izikulufu ze-Intermeshing zidala imiphumela yokugunda neyokuxova ukuze kuxutshwe umfaniswano. |

| Ukusebenza Okuphezulu Nokukhiqiza | Izikulufu ezijikelezayo zinika amandla amanani aphezulu wokukhiqiza nokusebenza kahle. |

| Ukuguquguquka | Iyakwazi ukucubungula ama-polymer ahlukahlukene kanye nokwakheka okuyinkimbinkimbi. |

Ubuthakathaka be-Twin Screw Extrusion

- Ama-twin screw extruder anesakhiwo esiyinkimbinkimbi nezindleko eziphakeme.

- Ukugeleza kwezinto ngaphakathi kwe-extruder kunzima ukumodela nokubikezela.

- Ukushintshashintsha kwengcindezi kungenzeka ngenxa ye-screw geometry.

- Ukuqapha usayizi wezinhlayiyana nokuzinza kwenqubo kuveza izinselele.

- Ukukhuphula kusuka elebhu kuya ekukhiqizeni kudinga ukulungiswa ngokucophelela.

Ukusetshenziswa Okuvamile Kwe-Twin Screw Extrusion

Ama-twin screw extruder adlala indima ebalulekile ezimbonini eziningi. Abakhiqizi bawasebenzisela ukuhlanganisa amapulasitiki, ukucubungula izinto ezigaywe kabusha, kanye nokukhiqiza ama-bioplastics. Imboni yokudla ithembele kuzo ukuze uthole ukudla okulula, okusanhlamvu, nokudla kwezilwane ezifuywayo. Izinkampani ezenza imithi zisebenzisa i-twin screw extrusion ukwenza amafomu omthamo oqinile. Imikhakha yamakhemikhali neyenjoloba nayo iyazuza ekuxubeni nasekulawuleni kwayo okunembayo. Imakethe yama-screw extruder angamawele iyaqhubeka nokukhula, iqhutshwa yisidingo e-Asia-Pacific, Europe naseNyakatho Melika.

I-Single Screw Extrusion vs Twin Screw Extrusion: Ukuqhathanisa Okubalulekile

Umehluko Wedizayini kanye Nenqubo

I-extrusion yesikulufu esisodwaisebenzisa isikulufu esisodwa esizungezayo esinephethini ye-helical elula. Lo mklamo uphusha impahla phambili ngomgqomo. Ngokuphambene, ama-twin screw extruder afaka izikulufu ezimbili ezihlanganayo. Lezi zikulufu zingazungezisa ngendlela efanayo noma eziphambene futhi ngokuvamile zihlanganisa amabhlogo okuxova ukuze kuxutshwe kangcono. Ithebula elingezansi ligqamisa umehluko omkhulu wezobuchwepheshe:

| Isici | I-Single Screw Extruder | I-Twin Screw Extruder |

|---|---|---|

| Isikulufa Design | Isikulufu esizungezayo esisodwa esinephethini ye-helical elula ephushela okubalulekile phambili. | Izikulufu ezimbili ezihlanganayo, okungenzeka zihlangane noma zizungezise, ezinamajiyometri ayinkimbinkimbi okuhlanganisa namabhulokhi okuxova. |

| Ukuxuba Amandla | Ifanele izinto ezilinganayo kanye nokuxuba okulula. | Ukuxuba okuphezulu ngenxa yezikulufu ezihlanganayo, okuvumela ukuhlakazeka okungcono kwezithasiselo nezigcwalisi. |

| Okokufaka nokuphumayo | Ngokuvamile aphansi amanani okuphumayo kanye nokuphumayo. | Ukuphuma okuphezulu nokuphumayo, kulungele ukukhiqizwa kwenani elikhulu. |

| Ukulawula izinga lokushisa | Ukulawula okuyisisekelo kwezinga lokushisa, isivinini sesikulufu, nokucindezela komgqomo. | Ukulawulwa kwezinga lokushisa okuthuthukisiwe ngokushisisa kwangaphakathi/izindawo zokupholisa eduze komgqomo. |

| Ukuphatha Izinto | Isebenza kahle kuma-thermoplastics, ama-elastomer, namapulasitiki agaywe kabusha anekhwalithi yomkhiqizo engaguquki. | Ifaneleka kangcono ukwakheka kwe-viscosity ephezulu, ezwela ukushisa, kanye neyinkimbinkimbi edinga ukulawula okunembile. |

| Ukuvumelana nezimo | Ukuguquguquka okuncane, ukusebenza okulula nokugcinwa. | Ukuvumelana nezimo okukhulu ngenxa yedizayini yesikulufu se-modular namapharamitha alungisekayo. |

| I-Degassing Amandla | Amandla akhawulelwe okukhipha umoya kanye nokuqeda amandla. | I-degassing esebenzayo kanye ne-devolatilization, ebalulekile ekulawuleni ikhwalithi. |

| Izibonelo Zohlelo Lokusebenza | Amafilimu epulasitiki, amapayipi, ukuhlanganisa, ukumbozwa ngocingo, ukukhishwa kweshidi, ukucubungula ukudla. | Ukuhlanganiswa kwe-polymer, ukucubungula ukudla, imithi, nokucubungula izinto eziyinkimbinkimbi. |

Abacwaningi abafana noShen et al. kanye noSastrohartono et al. babonise ukuthi ama-twin screw extruder anikezela ngezici zedizayini ezithuthuke kakhulu, njengokushear flux kanye nokusebenza kahle kwamandla, ikakhulukazi ezintweni eziyinkimbinkimbi.

Amakhono Okuxuba Nokucubungula

Amandla okuxuba nokucubungula ahlukanisa lobu buchwepheshe obubili. I-screw extrusion eyodwa isebenza kahle ezintweni ezilula, ezilinganayo. Ingakwazi ukusingatha imisebenzi eyisisekelo yokuhlanganisa, kodwa idonsa kanzima ngokuhlanganisa okuthuthukile noma ukwakheka okudinga ukulawula okunembayo. Ama-twin screw extruder ahamba phambili ekuxubeni. Izikulufu zabo ezihlanganisayo zenza ukugunda okuqinile kanye nemiphumela yokuxova. Lesi senzo siqinisekisa ngisho nokusatshalaliswa kwezithasiselo nama-filler, okubalulekile emikhiqizweni yekhwalithi ephezulu. Ama-opharetha angalungisa izinto eziyisikulufa kanye nezindawo zemiphongolo ukuze zilungise kahle inqubo yezinto ezihlukile. Ngenxa yalokho, amasistimu wezikulufu angamawele asekela izindlela zokupheka eziyinkimbinkimbi kanye nezidingo zokukhiqiza ezifunayo.

Qaphela: Kubakhiqizi abadinga ukuhlanganisa ama-polymer amaningi noma bengeze izihlungi, ama-twin screw extruder ahlinzeka ngenzuzo ecacile ekuxubeni ukusebenza.

Ukuphumelela kanye Nempumelelo

Ukusebenza kahle nokusebenza kahle kunendima enkulu ekukhetheni phakathi kwalezi zinhlelo. I-scrusion yesikulufu esisodwa ngokuvamile inikezela ngokuphuma okuphansi, okuyenza ifanele iziqondiso zokukhiqiza ezincane. Isebenza ngesivinini esihamba kancane sokucubungula futhi iletha imiphumela engaguquki yemikhiqizo ejwayelekile. Ngakolunye uhlangothi, ama-twin screw extruder, afinyelela izinga eliphezulu kanye nesivinini sokucubungula ngokushesha. Zisekela izidingo zomthamo omkhulu futhi zigcina ikhwalithi yomkhiqizo ngisho ne-granulation eyinkimbinkimbi. Ithebula elingezansi liqhathanisa amamethrikhi angukhiye:

| Imethrikhi | I-Single Screw Extruder | I-Twin Screw Extruder |

|---|---|---|

| Okokusebenza | Ukusebenza okuphansi, kulungele izinhloso zokukhiqiza eziphansi | Ukuphuma okuphezulu, kulungele izidingo zomthamo omkhulu |

| Isivinini sokucubungula | Isivinini sokucubungula esihamba kancane | Isivinini sokucubungula esisheshayo |

| Ikhwalithi Yomkhiqizo | Amandla okuhlanganisa alinganiselwe, imbudumbudu encane eyinkimbinkimbi | Ukuxuba okuthuthukisiwe, kusekela imbudumbudu eyinkimbinkimbi |

| Izindleko Zokusebenza | Izindleko zokusebenza eziphansi ngenxa yobulula nokusebenza kahle kwamandla | Izindleko zokusebenza eziphakeme ngenxa yobunkimbinkimbi nokunakekelwa |

| Ukuvumelana nezimo | Ukusebenza okuguquguqukayo okuncane, okulula | Ukuvumelana nezimo okukhulu, kungakwazi ukuphatha ukwakheka okuyinkimbinkimbi |

| Okukhipha Amanani | Amazinga okukhipha ngokuvamile aphansi | Amazinga aphezulu okukhiphayo |

Ama-twin screw extruder ngokuvamile athethelela izindleko zawo zokusebenza eziphezulu ngokukhuphuka kokukhiqiza kanye nekhono lokusingatha izinto eziyinselele kakhulu.

Ukuguquguquka nokuguquguquka

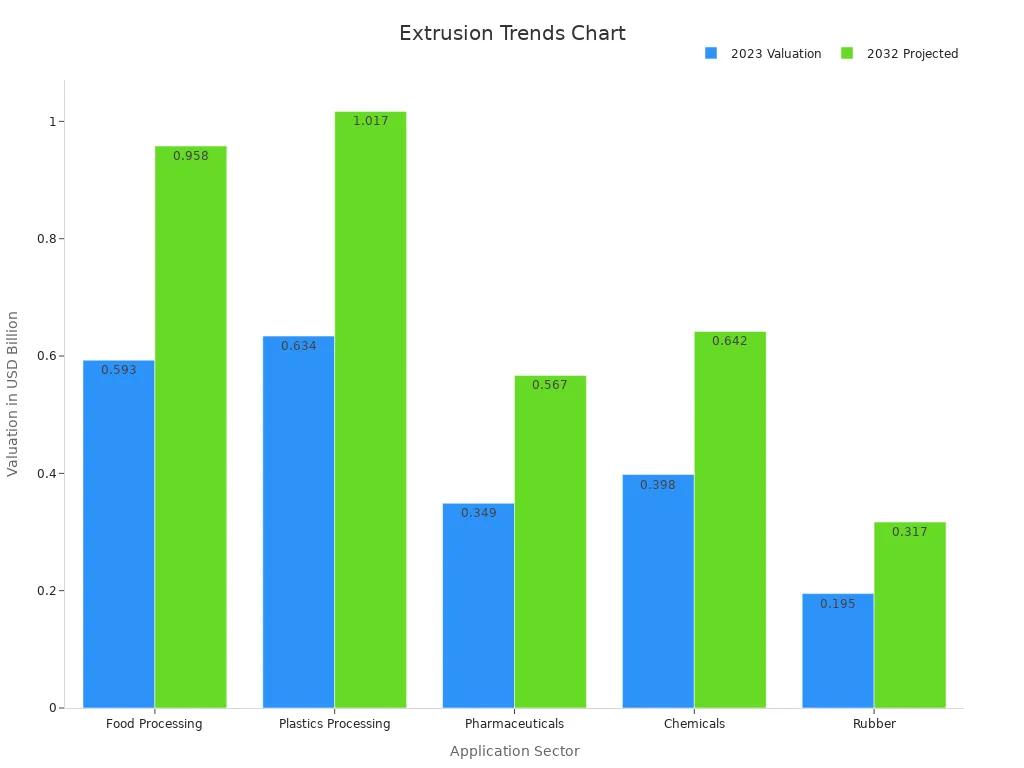

Ukuvumelana nezimo nokuguquguquka kubalulekile ekukhiqizeni kwesimanje. I-Single screw extrusion inikeza ukusebenza okuthembekile kwemikhiqizo ejwayelekile nezinto zokwakha. Nokho, inikeza ukuguquguquka okulinganiselwe lapho ushintsha phakathi kokwakheka okuhlukile noma izinhlobo zomkhiqizo. Ama-twin screw extruder agqamile kule ndawo. Embukisweni wezohwebo we-K 2016, imigqa eyisikulufu ethuthukisiwe ibonise ukushintsha okusheshayo phakathi kwezinto, imibala, nogqinsi. Amanye amasistimu ashintshe amafomethi ngamaminithi, hhayi amahora. Lawa ma-extruder acubungule amafilimu anezendlalelo eziningi anezendlalelo ezingafika kweziyi-11, izinto zokubamba ezifana ne-EVOH, inayiloni, namabanga ahlukahlukene e-polyethylene. Idatha yokukhiqiza ibonise a45.8% ukuncishiswa kokulahlwa kwezinto ezibonakalayokanye nokonga amandla okungaba ngu-29% ngemva kokuthuthukela kumasistimu wezikulufu zamawele amabili. Inzuzo yesikhathi sokutshala imali nayo ifinyezwe ngaphezu kuka-26%. Lokhu kuthuthukiswa kugqamisa izinzuzo zokusebenza zama-twin screw extruder ezindaweni eziyinkimbinkimbi, ezinezinto eziningi.

Izindleko Nokucatshangelwa Kwesondlo

Izindleko nokugcinwa kunomthelela esinqumweni sokugcina kubakhiqizi abaningi. Amasistimu e-screw extrusion eyodwa abiza kancane ukuthenga nokusebenza. Umklamo wabo olula usho izingxenye ezimbalwa zokugcina nokunciphisa ukusetshenziswa kwamandla. Ukunakekelwa okujwayelekile kuqondile, futhi isikhathi sokuphumula sihlala sincane. Ama-twin screw extruder adinga ukutshalwa kwezimali okuphezulu kokuqala. Isakhiwo sabo esiyinkimbinkimbi nezici ezithuthukisiwe ziholela ekwandeni kwezidingo zokunakekelwa kanye nokusetshenziswa kwamandla okuphezulu. Kodwa-ke, ezinkampanini ezikhiqiza imikhiqizo enenani eliphezulu noma eyinkimbinkimbi, izinzuzo zokuguquguquka, ukuphuma, kanye nekhwalithi kuvame ukudlula izindleko ezengeziwe. Ukukhetha isistimu efanele kuncike ekulinganiseni lezi zici nemigomo yokukhiqiza kanye nesabelomali.

Ukukhetha I-Extruder Elungile Yezidingo Zakho

Ukufaneleka Kwezinto ezibonakalayo

Ukukhetha i-extruder efanele kuqala ngokuqonda ukuhambisana kwezinto. Izingxenye zomshini ezibalulekile njengeisivinini sesikulufu, ububanzi, nesilinganiso sobude ukuya kububanzikuthinta indlela i-extruder esebenza ngayo izinto ezahlukene. Isibonelo, izilinganiso eziphezulu ze-L/D zisiza ngezinto eziyinkimbinkimbi ezidinga ukuncibilika okuphelele nokuxutshwa. Idizayini yemigqomo, okuhlanganisa izindawo zokushisa nokukhipha umoya, isekela izinto ezizwelayo noma ezigaywe kabusha. Imihlahlandlela yemboni incoma ukufanisa i-extruder nezinga lokushisa lokucubungula, i-viscosity, nezinga lokugeleza. I-screw extrusion eyodwa isebenza kahle ekucutshungulweni kwenqwaba ye-thermoplastics, kuyilapho ama-twin screw extruder aphatha ukwakheka okuyinkimbinkimbi ezimbonini zokudla, ezemithi, ne-polymer.

Isikali Sokukhiqiza kanye Nomphumela

Izinga lokukhiqiza kanye nezidingo zomkhiqizo zidlala indima enkulu ekukhetheni i-extruder. Amazinga aphezulu okukhiphayo angakhuphula ukusetshenziswa kwamandla nezidingo zokunakekelwa. Ukucushwa kwesikulufu se-modular kuvumela ukukala nokusebenza okungcono. Ucwaningo lubonisa lokhoizinga lokuphuma kanye nokugcwaliswa komthelela wezinga lomkhiqizo nokusebenza kahle kokuxuba. Ama-extruder amakhulu adinga ukulungiswa ngokucophelela kwemingcele yokusebenza ukuze kugcinwe imiphumela engashintshi. Izinkampani kufanele zilinganisele imigomo yokukhiqiza nezindleko zokusebenza kanye nobunzima bobuchwepheshe.

Isabelomali kanye Nezindleko

Ukucatshangelwa kwezindleko kufaka phakathi izindleko ezingaphambili neziqhubekayo. Ithebula elingezansi libonisa izici zezindleko ezibalulekile:

| I-Cost Factor | Incazelo | Umthelela Wesabelomali |

|---|---|---|

| Ukuthenga Kokuqala | Iyahlukahluka ngosayizi nohlobo | Ukutshalwa kwezimali okukhulu kwangaphambili |

| Isitifiketi | ISO 9001, CE, njll. | Ingase yenyuse intengo yokuthenga |

| Isondlo | Kudingeka isevisi evamile | Izimali eziqhubekayo zonyaka |

| Ukusetshenziswa kwamandla | Amamodeli asebenzayo asindisa izindleko zesikhathi eside | Okuphezulu phambili, okuphansi nyanga zonke |

| Ukuqeqeshwa | Iyadingeka ukuze usebenze kahle | 1-3% yenani lokuthenga |

Abakhiqizi e-Asia-Pacific bavame ukuhlomula ezindlekweni zokusebenza eziphansi ngenxa yezinzuzo zesifunda.

Izincomo ezisekelwe kuhlelo lokusebenza

Niniukukhetha isistimu ye-extrusion, izinkampani kufanele zicabangele umthamo wokukhiqiza, ukuguquguquka kwabahlinzeki, kanye nezimfuneko zekhwalithi. Ngemikhiqizo eyisisekelo kanye nokugijima kwezinga elincane, i-screw extrusion eyodwa inikeza ubulula nezindleko eziphansi. Ama-extruder ama-twin screw afanelana nevolumu ephezulu, eyinkimbinkimbi, noma imikhiqizo emisha edinga ukuxutshwa okuthuthukile nokuguquguquka. Izimboni ezifana nezezimoto, ezokudla, nemithi ngokuvamile zikhetha amasistimu ngezikulufu ezimbili ngenxa yokuhlukahluka kwazo kanye nekhwalithi yomkhiqizo. Izinkampani ezihlose ukuhlukaniswa kwemakethe zingashintshela ku-twin screw extrusion ukuze zizuze izici ezihlukile zomkhiqizo.

- Ama-extruder ama-twin screwsebenzisa izikulufu ezimbili ukuze uthole ukuxuba okungcono nokugeleza kwezinto ezinzile.

- Baphatha izinhlobo zezinto ezibonakalayo eziningi futhi banikeza ukukhiqiza okuphezulu.

- I-scrusion yesikulufa esisodwa isebenza kangcono ezintweni ezilula, ezine-viscosity ephansi.

- Ngemikhiqizo eyinkimbinkimbi noma ukusebenza kahle okuphezulu, izinkampani kufanele zikhethe ama-twin screw extruder.

FAQ

Uyini umehluko omkhulu phakathi kwesikulufa esisodwa kanye ne-twin screw extrusion?

I-scrusion yesikulufu esisodwa isebenzisa isikulufu esisodwa ekucubunguleni okuyisisekelo. I-twin screw extrusion isebenzisa izikulufu ezimbili zokuxuba okungcono nokubamba izinto eziyinkimbinkimbi.

Iyiphi i-extruder esebenza kangcono ekugayweni kabusha kwamapulasitiki?

Ama-twin screw extruder aphatha amapulasitiki agaywe kabusha kahle kakhulu. Banikeza ukuxuba nokulawula okungcono, okuthuthukisa ikhwalithi yomkhiqizo.

Ukunakekela kuqhathaniswa kanjani phakathi kwalezi zinhlobo ezimbili?

I-screw extruder eyodwa idinga ukulungiswa okuncane.Ama-twin screw extruder adinga ukunakwa okwengeziwengenxa yomklamo wabo oyinkimbinkimbi kanye nezingxenye ezengeziwe.

Isikhathi sokuthumela: Jul-08-2025