Uma ngibona umonakalo obonakalayo wendawo, ukuvinjwa okuphindelelayo, noma ikhwalithi yomkhiqizo engahambisani ku-Parallel Twin Screw Barrel For Extruder, ngiyazi ukuthi sekuyisikhathi sokucabangela ukumiselela. Ukutholwa kusenesikhathi konga izindleko futhi kugcina ukukhiqiza kusebenza kahle. Ngibheka njalo wamiI-Twin Plastic Screw Barrel, I-Conical Twin Screw Twin Screw, futhiI-Twin Screw Extruder Barrelszalezi zimpawu zokuxwayisa.

Ukugqoka Okudlulele Ku-Parallel Twin Screw Barrel For Extruder

Ukulimala Okubonakalayo Kobuso

Lapho ngihlola yamiI-Parallel Twin Screw BarrelKu-Extruder, ngibheka izimpawu ezicacile zokulimala kwendawo. Ngivame ukubona ama-grooves ajulile kuma-screw element, ngezinye izikhathi afinyelela ku-3 mm. Ukulimala okukhulu komshini endaweni engaphakathi yomgqomo kugqama ngaso leso sikhathi. Ngiphinde ngibheke ukuqhekeka kwethiphu ye-screw shaft kanye nanoma yimuphi umonakalo endandatho ye-visco-seal. Ngezinye izikhathi, ngiqaphela ukudlidliza okungavamile ngaphambi kokwehluleka. Lezi zimpawu eziyisixwayiso zingitshela ukuthi umgqomo noma izikulufi zingadinga ukushintshwa maduze.

- Ukulimala okukhulu kwemishini ngaphakathi komgqomo

- I-grooving ejulile kuma-screw elements (kufika ku-3 mm)

- Ukususwa ekugqokeni, ngezinye izikhathi kuze kufike ku-26 mm

- Imifantu ethiphu ye-screw shaft noma iringi ye-visco-seal eyonakele

- Amazinga okudlidliza angajwayelekile ngaphambi kokwehluleka

Izinguquko Zobubanzi Bemigqomo

Ngihlale ngikala ububanzi bomphongolo ukuze ngibheke ukuguga. Amazinga emboni aphakamisa ukuthi ukubekezelela ukugqokwa okwamukelekile komgqomo kuphakathi kuka-0.1 no-0.2 mm (0.004 kuya ku-0.008 amayintshi). Uma ngibona ububanzi bushintshile ngale kwemikhawulo, ngiyazi ukuthi umgqomo usugugile. Nasi isithenjwa esisheshayo:

| Isakhi | I-Wear Tolerance (mm) | I-Wear Tolerance (amayintshi) |

|---|---|---|

| Isikulufu | 0.1 | 0.004 |

| Umgqomo | 0.1 kuye ku-0.2 | 0.004 ukuze 0.008 |

Ukwenyuswa Kwesikulufu-emgqonyeni

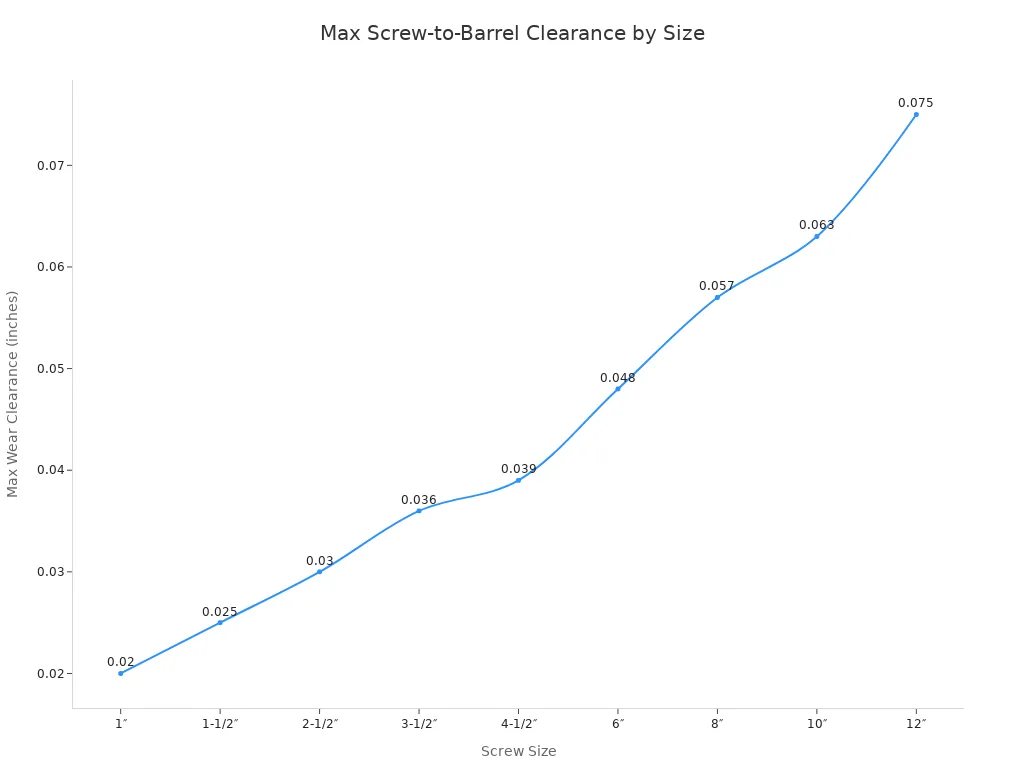

Nginaka kakhulu igebe phakathi kwesikulufa nomgqomo. Uma le mvume ikhula kakhulu, izinkinga ziqala ukuvela. Ishadi elingezansi libonisa ukucaciswa okuphezulu okunconyiwe kosayizi abahlukene bezikulufu:

Lapho igebe landa, ngibona ukugeleza okuthe xaxa nokuvuza kwepulasitiki. Lokhu kubangela ukuguquguquka kwengcindezi nevolumu. Ipulasitiki ingashisa, okulimaza ikhwalithi yomkhiqizo. Ngokuvamile ngidinga ukwandisa isivinini somshini kanye nokusebenzisa amandla ukuze nje ngiqhubeke. Igebe elincane ligcina yonke into ivaliwe futhi isebenza kahle, kodwa igebe elikhulu liholela ekuvuzeni nasekuphumeni okuphansi. Uma ngibona lezi zinkinga, ngiyazi ukuthi i-Parallel Twin Screw Barrel For Extruder idinga ukunakwa.

Ukusebenza Okuncishisiwe Kwe-Parallel Twin Screw Barrel For Extruder

Izilinganiso Zokukhipha Eziphansi

Lapho ukusebenza kwe-extruder yami kwehla, ngikubona ngaso leso sikhathi. Umshini ukhiqiza izinto ezincane ngesikhathi esifanayo. NgiyahlolaI-Parallel Twin Screw Barrel For Extruderngezimpawu zokuguga. Izikulufu ezigugile noma imiphongolo ibambezela ukunyakaza kwepulasitiki. Lokhu kusho ukuthi ngithola imikhiqizo embalwa eqediwe ihora ngalinye. Kwesinye isikhathi, ngibona i-hopper ihlala igcwele isikhathi eside kunokujwayelekile. Lokhu kungitshela ukuthi umshini awukwazi ukuhambisana nesidingo.

Ikhwalithi Yomkhiqizo Engahambisani

Ngihlala ngibheka izinguquko kwikhwalithi yemikhiqizo yami. Uma ngibona izindawo ezimaholoholo noma izimo ezingalingani, ngiyazi ukuthi kukhona okungalungile. Imiphongolo nezikulufi ezigugile kungabangela ukuxubana okungalungile nokuncibilika ngokungalingani. Lokhu kuholela ezinkingeni ezinjengokuphuka kwe-ncibilika noma ukwakheka kokufa. Nali ithebula elibonisa izindaba ezijwayelekile zekhwalithi yomkhiqizo ezixhunyaniswe nokuguga kwemiphongolo:

| Udaba Lwekhwalithi Yomkhiqizo | Incazelo |

|---|---|

| Ukuguga Nokukhala Okudlulele | Kuholela ekuncishisweni kokukhishwayo, ukuxutshwa okungaguquki, kanye nezindleko zokulungisa ezikhuphukayo. |

| Ncibilikisa Ukuphuka | Imiphumela endaweni engalungile noma engajwayelekile, ethinta ukubukeka nezakhiwo zemishini. |

| I-Die Build-up | Ibangela ikhwalithi ephansi ephansi kanye nokungahambisani kwe-dimensional ngenxa yokuwohloka kwe-polymer. |

Uma ngibona lezi zinkinga, ngiyazi ukuthi sekuyisikhathi sokuhlola umgqomo nezikulufu.

Ukwenyuka Kokusetshenziswa Kwamandla

Nginaka kakhulu izikweletu zami zamandla. Uma i-extruder isebenzisa amandla amaningi kunangaphambili, ngiyazi ukuthi ukusebenza kahle kwehlile. Izikulufu ezigugile ziphoqa umshini ukuthi usebenze kanzima. Lokhu kwandisa ukusetshenziswa kwamandla kanye nezindleko. Mina njalohlola izikulufu nomgqomouma ngibona ukwenyuka kokusetshenziswa kwamandla. Ukushintsha izingxenye ezigugile kusiza ukubuyisela ukusebenza kahle futhi konga imali.

Izinkinga Ezivamile Zokulungisa Nokulungisa

Ukuvinjwa Okuphindaphindiwe noma Ama-Jam

Ngivame ukubhekana nokuvinjwa noma ukuminyana ku-extruder yami lapho isistimu ingasebenzi kahle. Kunezici ezimbalwa ezingabangela lezi zinkinga:

- Ukubuyisela emuva amabhlogo okuxova ngezinye izikhathi kudala izindawo ezinengcindezi ephezulu, eziholela ekucineni nasekuvinjweni.

- Ukucaciswa okudlulele phakathi kwesikulufu nomgqomo kuvumela okokusebenza ukuthi kugeleze kuhlehle emuva, kubangele ukushintsha kwevolumu nokuma.

- Izindiza ezigugile ngezikulufu noma ukuklwebheka ngaphakathi komgqomo kuphazamisa inqubo yokuhlanganisa. Lokhu kubangela izinhlayiya ezingancibilikisiwe kanye nobukhulu bezinto ezingalingani.

- Uma idizayini yesikulufu ingafani nezakhiwo ezibonakalayo, ngibona umthwalo ukhuphuka ngokuzumayo noma ngisho nokuma kwempahla, okungamisa ukukhiqizwa.

Uma ngibona lezi zinkinga, ngiyaziimishini yami idinga ukunakwa.

Imisindo Engajwayelekile noma Ukudlidliza

Imisindo eyinqaba noma ukudlidliza kuhlala kubamba ukunaka kwami ngesikhathi ngisebenza. Le misindo ivame ukukhomba izinkinga ezijulile. Ngifunde ukubukela okulandelayo:

| Uhlobo Lokuhluleka | Imbangela | Ukusebenza |

|---|---|---|

| Amabhere alimele | Ukusetshenziswa isikhathi eside, ukugcotshwa okungalungile, ukugcwala ngokweqile, noma ukufakwa okungafanele | Ukudlidliza okungeziwe nomsindo, ukuzungezisa isikulufu okungaguquki, ukungaqondani kahle kwesikulufu okungenzeka |

| Ukuhluleka kwe-gearbox | Ukugqokwa, ukuntuleka kokugcotshwa, ukungcoliswa uwoyela, noma umthwalo oweqile | Umsindo wegiya, izinga lokushisa eliphezulu likawoyela, ukusebenza kahle okuphansi, ingozi yokuphuka kwamagiya |

Kwesinye isikhathi, ngiphinde ngizwe imisindo eyinqaba evela ekungaqondani kahle, ama-bearings aphukile, noma ngisho nezinto zangaphandle ngaphakathi komgqomo. Lezi zimpawu zingitshela ukuthi ngime futhi ngihlole i-Parallel Twin Screw Barrel For Extruder ngokushesha.

Imvamisa Ephakeme Yokulungisa

Uma ngizithola ngilungisa i-extruder kaningi, ngiyazi ukuthi kukhona okungalungile.Ukulungisa njalo kushouhlelo luyaguga. Ngilandelela ukuthi ngishintsha kangaki izingxenye noma ngilungisa ama-jam. Uma ishejuli yokulungisa iba mfishane, ngicabanga ukushintsha umgqomo noma izikulufu. Lokhu kungisiza ngigweme ukwehluleka okukhulu futhi kugcine ulayini wami wokukhiqiza usebenza kahle.

Ukuvuza Kwempahla noma Ukungcoliswa Ku-Parallel Twin Screw Barrel For Extruder

Izimpawu zokuvuza Around Barrel

Uma ngigijima i-extruder yami, ngihlala njalohlola ukuvuzanxazonke emgqonyeni. Ukuvuza kungabonisa izinkinga ezinkulu ngaphakathi komshini. Ngivame ukubona amachibi amancane ezinto ezincibilikisiwe eduze kwembobo yokukhipha umoya noma eduze kwamajoyinti emiphongolo. Kwesinye isikhathi, ngibona iphunga elishisayo noma intuthu, okungitshela ukuthi impahla ibaleka lapho kungafanele khona.

Izinkinga eziningana zingabangela lokhu kuvuza:

- Ukubuyela emuva kokubalulekile okuvela kumklamo wesikulufa ongenangqondo

- Imbobo yokukhipha umoya embi noma idizayini yokukhipha umoya ebamba izinto ezincibilikisiwe

- Ukugqokwa komshinilokho kwandisa igebe phakathi kwesikulufa nomgqomo

- Ukulawula izinga lokushisa okungalungile, okungashisa futhi kulimaze umgqomo

- Ukucubungula izinto ezilimazayo noma ukusebenzisa umshini isikhathi eside, okwandisa ukuguga

- Izinkinga zokugcoba eziphakamisa ukungqubuzana futhi zibangele ukuguga okwengeziwe

Uma ngibona noma yiziphi zalezi zimpawu, ngiyazi ukuthi i-Parallel Twin Screw Barrel For Extruder idinga ukubhekisiswa.

Ukungcola Emkhiqizweni Wokugcina

Ngihlale ngihlola imikhiqizo yami eqediwe ukuze ngibone izimpawu zokungcola. Lapho umgqomo uguga noma wehluleka, ngivame ukubona izinguquko ekubukekeni namandla omkhiqizo. Ithebula elingezansi libonisa okunyeizinkinga ezivamilenokuthi zibukeka kanjani:

| Inkinga | Umthelela Kukhwalithi Yomkhiqizo | Izimpawu Ezibonakalayo |

|---|---|---|

| I-Surface Delamination | Izendlalelo ezibuthakathaka, ezixebukayo, noma ezicwebezelayo | Ukucwecwa noma ukucwayiza ebusweni |

| Ukushintsha umbala | Imibala egqamile, ama-patches angavamile, amandla ancishisiwe | Amabala noma amabala anombala ongajwayelekile |

| Splay Marks | Izingxenye eziqinile, ukumelana nomthelela omubi, amamaki angaphezulu | Imibala esiliva noma eguqubele |

Uma ngibona lezi zinkinga, ngiyazi ukuthi ukungcola noma ukuguga ngaphakathi komgqomo cishe kuyimbangela. Ngithatha isinyathelo ngokushesha ukuze nginqande umonakalo omkhulu futhi ngigcine imikhiqizo yami isezingeni eliphezulu.

Izinselelo Zokuphelelwa yisikhathi Nokuhambisana

Idizayini Yemigqomo Ephelelwe yisikhathi

Ngivame ukubona ama-extruder amadala azabalaza ukuhambisana nezidingo ezintsha zokukhiqiza. Lapho ngisebenzisa iumklamo we-barrel ophelelwe yisikhathi, ngiyaqaphela ukuthi ayikwazi ukuphatha izinto zakamuva noma ilethe ukusebenza kahle okufana nokokusebenza kwesimanjemanje. Kule minyaka eyishumi edlule, abakhiqizi benze intuthuko enkulu emiphongolweni yesikulufu esingamawele amabili. Lezi ntuthuko zingisiza ukuthi ngicubungule izinhlobo eziningi zamapulasitiki nezithasiselo. Ngithembele kumiklamo yakamuva ukuze ngithuthukise okukhiphayo futhi ngithuthukise ikhwalithi yomkhiqizo. Nali ithebula elibonisa ezinye zezinguquko ezibaluleke kakhulu:

| Intuthuko | Umthelela Ekusebenzeni |

|---|---|

| Ibanga lokucubungula izinto ezithuthukisiwe | Ikhono lokucubungula izinto ezibonakalayo ezibonakalayo neziyinkimbinkimbi |

| Amazinga aphezulu okukhiphayo | Izinga lokukhiqiza elinyukile uma liqhathaniswa nama-extruder anesikulufu esisodwa |

| Ukuncipha kokuwohloka kokushisa | Isikhathi sokuhlala esifushane esiholela kukhwalithi engcono yezinto ezibonakalayo |

| Imiklamo ye-modular | Ukusebenza okuthuthukisiwe kokuxuba kanye nokuguquguquka kokusebenza |

Uma ngiqhathanisa okokusebenza kwami kwakudala nalezi zici ezintsha, ngibona ukuthi ngiphuthelwa kangakanani ngokungathuthukisi.

Ukungahambisani Nezinto Ezintsha noma Izinqubo

Ngokuvamile ngidinga ukusebenza ngama-polymer amasha noma izithasiselo. Kwesinye isikhathi, i-Parallel Twin Screw Barrel yami endala ye-Extruder ayikwazi ukuphatha lezi zinguquko. Ngibona ukuxutshwa okungalungile, ukuncibilika okungalingani, noma ukuminyana komshini. Imiphongolo emisha isebenzisa izakhi zesikulufu se-modular nokulawula izinga lokushisa okungcono. Lezi zici zingivumela ukuthi ngishintshe izinto noma ngishintshe izinqubo ngokushesha. Uma umgqomo wami ungaqhubeki, ngizifaka engcupheni yokulahlekelwa ibhizinisi noma ngisale ngemuva kwezimbangi. Ngihlale ngibheka ukuthi okokusebenza kwami kuyahambisana yini nezidingo zemboni yakamuva ngaphambi kokuqala iphrojekthi entsha.

Amathiphu Okuhlola Nokuqapha E-Parallel Twin Screw Barrel For Extruder

Ukuhlola Okubonakalayo Okujwayelekile

Ngihlale ngiqala usuku lwami ngokuhamba ngokucophelela eduze kwe-extruder yami. Ngibheka imifantu emiphongolweni noma amazinyo ohlaka. Ngibheka amabhawodi axegayo futhi ngiwaqinise ngokushesha ukuze ngimise ukudlidliza. Ngenza isiqiniseko sokuthi isistimu yokugcoba igcwele futhi ngibheka ukuvuza. Ngiphinde ngihlole isistimu yokupholisa ukuze ngibone ukuthi izinga lokupholisa nokugeleza kulungile. Ngibheka zonke izixhumo zikagesi ukuze ngiqiniseke ukuthi ziphephile futhi azilimalanga. Ngibheka izikulufu ukuze ngibone izimpawu zokuguga noma ukungcola. Amathiphu okundiza kufanele ahlale ebukhali, futhi akufanele kube nesikhala esikhulu phakathi kwesikulufu nomgqomo. Uma ngibona imihuzuko noma ukugqwala ngaphakathi komgqomo, ngilungisa inkinga ngaphambi kokuqala ukukhiqiza.

Ithiphu: Ngihlala ngikhuluma nanoma iyiphiukuvuza emapayipini noma emapayipiningokushesha ukugwema ukumosha impahla.

Ukulinganisa Ukugqokwa Nokubekezelelana

Ngisebenzisa amathuluzi anembayo ukukala ububanzi bomphongolo kanye nokucaciswa kwesikulufu emgqonyeni. Ngiqhathanisa izilinganiso zami nokubekezelelana okunconyiwe. Uma ngibona ububanzi bomphongolo noma igebe selikhule kakhulu, ngiyazi ukuthi sekuyisikhathi sokuhlelela ukulungiswa noma ukushintshwa. Ngigcina ilogi yalezi zilinganiso ukuze ngibone izinguquko ngokuhamba kwesikhathi. Lokhu kungisiza ukuba ngibambe izinkinga kusenesikhathi futhi ngigcine ezamiI-Parallel Twin Screw BarrelI-Extruder isebenza kahle.

Ukubonisana Nezinkombandlela Zomkhiqizi

Ngihlala ngifunda imanuwali yomkhiqizi ngaphambi kokwenza noma yiziphi izinguquko. Imanuwali inginika ukubekezelelana okufanele, amashejuli okulungisa, kanye nezinyathelo zokuhlola. Ngilandela iseluleko sabo sokuhlanza, ukuthambisa, nokufaka izingxenye esikhundleni. Uma nginemibuzo, ngithintana nomkhiqizi ukuze ngithole usizo. Lokhu kungisiza ukuthi ngivikele okokusebenza kwami futhi ngigcine umugqa wami wokukhiqiza uphephile.

Ukwenza Isinqumo Sokushintsha

Ukuhlaziywa Kwezindleko-Inzuzo

Uma ngithatha isinqumo sokuthi ngifake esikhundleni se-Parallel Twin Screw Barrel For Extruder, ngihlala ngiqala ngeukuhlaziywa kwezindleko zenzuzo. Ngibheka izici ezimbalwa ezibalulekile ezithinta iphuzu lami elibalulekile. Ngifuna ukwenza isiqiniseko sokuthi utshalomali lwami luzokhokha ngokuhamba kwesikhathi. Nali ithebula elingisiza ukuqhathanisa amaphuzu abalulekile:

| Isici | Incazelo |

|---|---|

| Ukusebenza Kwamandla | Ukonga amandla kuholela ekwehlweni kwezindleko zesikhathi eside, okuthuthukisa ukuncintisana embonini. |

| I-Lifespan Yezisetshenziswa | Idizayini eqinile nezingxenye ezihlala isikhathi eside zelula isikhathi sokuphila sezikulufu nemiphongolo, kunciphisa izindleko zokushintshwa. |

| Izindleko Zokulungisa | Ukunakekelwa okuvamile kunganciphisa isikhathi sokuphumula futhi kugweme ukulungiswa kwezimo eziphuthumayo ezibizayo, kuthinte izindleko zizonke. |

| Ukuvumelana Kwekhwalithi | Ikhwalithi engaguquki ivimbela ukonakala komkhiqizo nezindaba zokulawula, ezingase zibe nezindleko ezengeziwe. |

| Ukusebenza Ngempumelelo | Ukusebenza kahle okuthuthukisiwe kunciphisa ukusetshenziswa kwamandla futhi kukhuphule ukusebenza, okuthinta inzuzo iyonke. |

Ngibuyekeza isici ngasinye futhi ngizibuze ukuthi ingabe umgqomo wamanje uhlangabezana nezidingo zami. Uma ngibona ukunyuka kwezindleko zamandla noma ukulungiswa njalo, ngiyazi ukuthi sekuyisikhathi sokuthatha isinyathelo. Ikhwalithi yomkhiqizo engaguquki nayo ibalulekile. Uma ngibona ukukhubazeka, ngicabangela izindleko zokulahleka kokuthengisa kanye nezikhalazo zamakhasimende. Ngokukala lawa maphuzu, ngenza isinqumo esihlakaniphile sebhizinisi lami.

Ukushintshwa Kwesikhathi Ukuze Unciphise Isikhathi Sokuphumula

Ngihlala ngihlela ukufaka esikhundleni sami ukuze ngigcine isikhathi sokuphumula siphansi ngangokunokwenzeka. Ngihlela umsebenzi ngezikhathi zokukhiqiza ezihamba kancane noma amawindi okulungisa. Ukucophelela kwesikhathi kuyangisiza ukuthi ngigweme ukulahleka kwemali engenayo futhi kugcina iqembu lami likhiqiza. Ngisebenzisa ithebula ukulandelela izinzuzo zokuhlela okuhle:

| Zuza | Ukwehliswa Kwephesenti |

|---|---|

| Izinga lokumosha | 12–18% |

| Izindleko zamandla | 10% |

| Isikhathi sokuphumula | kufika ku-30% |

Uma ngishintsha umgqomo ngesikhathi esifanele, ngibona ukumosha okuncane kanye nezindleko zamandla eziphansi. Ithimba lami liqeda umsebenzi ngokushesha, futhi ukukhiqiza kuqala futhi ngokushesha. Ngihlale ngixhumana nabasebenzi bami nabahlinzeki bempahla ukuze ngiqinisekise ukuthi konke kuhamba kahle. Isikhathi esihle sivikela inzuzo yami futhi sigcina amakhasimende ami ejabule.

Ngihlala ngibheka lezi zimpawu empilweni yamii-parallel twin screw barrelokwe-extruder:

- Ngiqapha igebe lokuguga; ukulungiswa kusebenza kuze kube0.3mm, kodwa ngishintsha umgqomo uma igebe likhula noma ungqimba lwe-nitriding lwehluleka.

- Ngikala izindleko zokulungisa ngokushintshwa nokuguga kwethrekhi ukuze ngigweme isikhathi sokuphumula.

- Ngihlola imishini yami njalo500–1,000 amahora.

- Ukuhlola okuvamile kungisiza ngibambe izinkinga kusenesikhathi.

Ukuqapha okuvamile kugcina ukukhiqiza kwami kusebenza kahle futhi konga imali.

FAQ

Kufanele ngihlole kangaki umphongolo wami wesikulufu ohambisanayo ukuze uguge?

Ngihlola umgqomo wami njalo ngamahora okusebenza angama-500 kuye kwayi-1,000. Ukuhlola okuvamile kungisiza ukuba ngibambe izinkinga kusenesikhathi futhi ngigcine i-extruder yami isebenza kahle.

Ithiphu: Ngihlala ngingena emiphumeleni yokuhlola ukuze ngiyisebenzise esikhathini esizayo.

Ingakanani imvume enkulu yokususa isikulufu emgqonyeni ngaphambi kokushintshwa?

Ngishintsha umgqomo lapho igebe le-screw-to-barrel lidlula u-0.3 mm. Lokhu kuvimbela ukuvuza futhi kugcina izinga lomkhiqizo liphezulu.

| Isakhi | Ukucaciswa Okukhulu (mm) |

|---|---|

| Isikulufu-emgqonyeni | 0.3 |

Ngingakwazi ukulungisa umphongolo ogugile esikhundleni sokuwushintsha?

Ngilungisa izingubo ezincane ezifika ku-0.3 mm. Uma isendlalelo se-nitriding sihluleka noma umonakalo mkhulu, ngikhetha ukumiselela ukuze ngisebenze kangcono.

Isikhathi sokuthumela: Aug-28-2025