Ubuchwepheshe be-twin screw extruder bunikeza ukuxuba okuthuthukisiwe nokuphuma okuphezulu, okubenza bufanelekele imisebenzi enzima yokucubungula ipulasitiki. Ama-scruder angama-screw single ahlala edumile ngokungabizi kwawo kanye nokusebenza kahle. Ukukhula kwemakethe kukhombisa isidingo esinamandla, izimboni ezifana nokupakisha nezimoto zithembele kule mishini ukuze kukhiqizwe ngezinga elikhulu.I-Twin Parallel Screw Barel SupplierfuthiIzikulufo Ezimbili Zezikhiqizo Zepulasitikiqinisekisa imiphumela engaguquki, ngenkathiI-Conical Twin Screw Twin Screwimiklamo ithuthukisa ukuguquguquka.

Izimiso Zokusebenza kanye Nomehluko Womklamo

Ukucushwa kwe-Twin Screw Extruder

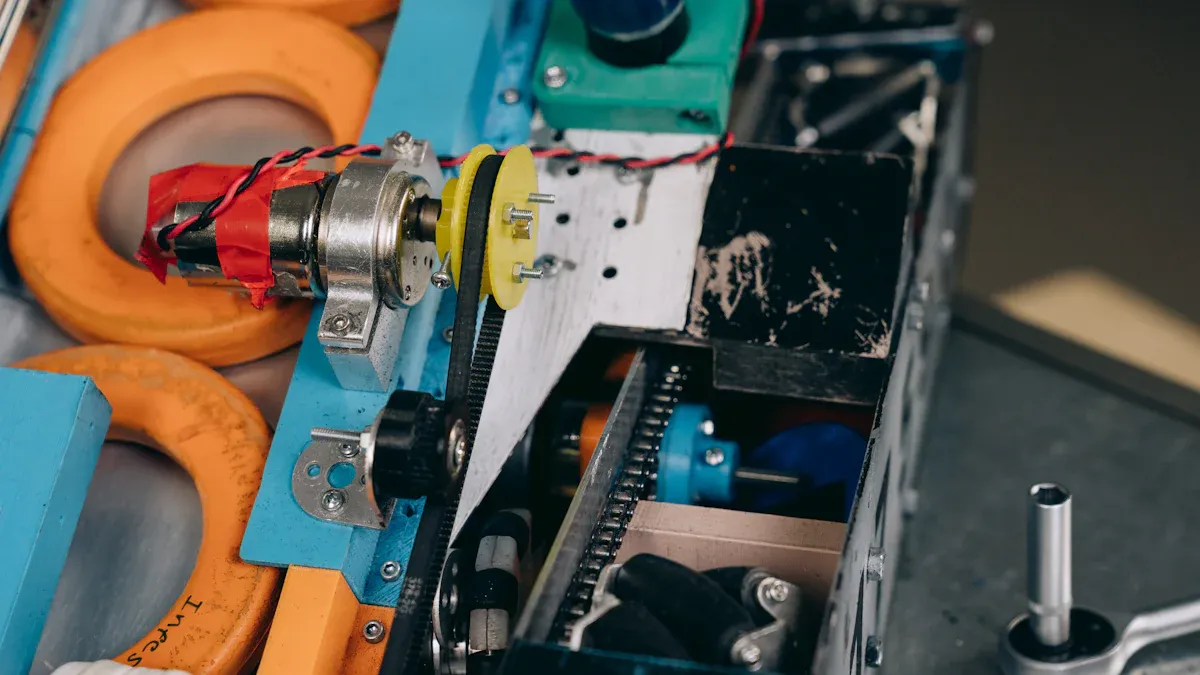

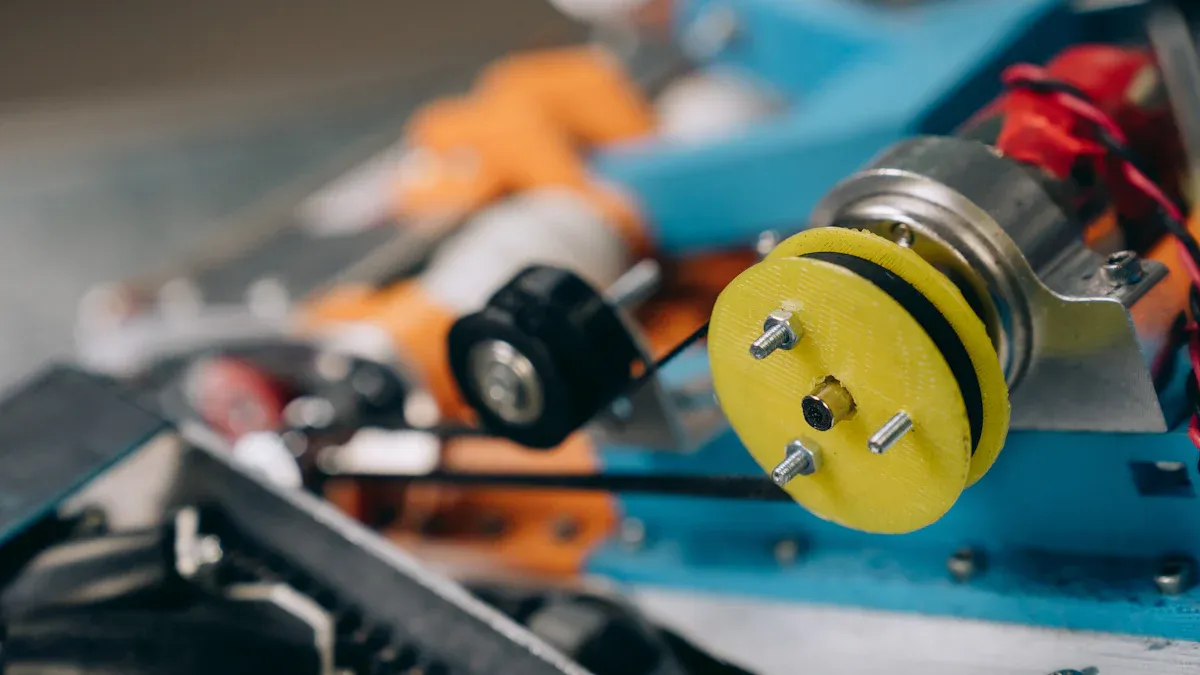

Kusetshenziswa ama-twin screw extrudersizikulufo ezimbili ezihlanganayoezijikeleza ndawonye emgqonyeni. Lezi zikulufu zingazungezisa ngokuhlanganyela noma ziphenduke, kuye ngohlelo lokusebenza. Idizayini ivumela ukuxuba okuthuthukisiwe nokuhlanganiswa, okwenza kube nokwenzeka ukucubungula izinto eziningi ezihlukahlukene. Onjiniyela bangalungisa i-screw diameter, iphrofayili, kanye nejometri yomgqomo ukuze kuthuthukiswe izinga lokuphumayo kanye nekhwalithi yomkhiqizo. Ukwakhiwa kwemiphongolo ye-modular kanye nezinhlelo zokulawula ezithuthukisiwe zisiza ukugcina izinga lokushisa elinembile nokucindezela. Lezi zici zithuthukisa ukufana komkhiqizo kanye nezakhiwo zemishini, ikakhulukazi ezinhlelweni ezifunwa kakhulu ezifanaUkukhiqizwa kwepayipi le-PVC.

Qaphela:Idizayini ye-intermeshing ikhulisa ukusebenza kahle kokuxuba futhi isekela ukuzihlanza, okunciphisa isikhathi sokuphumula.

I-Single Screw Extruder Design

Ama-extruder angama-screw single anomklamo olula onesikulufu esisodwa se-helical ngaphakathi kombhobho. Lo mklamo usebenzisa izingxenye ezimbalwa ezihambayo, okwenza kube lula ukusebenza nokuyinakekela. Isikulufu siphushela okubalulekile phambili ikakhulukazi ngokugeleza kokudonsa, okusebenza kahle ezintweni ezigelezayo ezingaguquki. Ukupholisa isikulufu sangaphakathi kanye nomumo wentambo engunxande kusiza ukuphatha izinga lokushisa nokuqinisekisa ukucubungula okuzinzile. Usayizi ohlangene kanye nokwakhiwa okuqondile kwenza ama-scruder angama-screw extruder engabizi futhi afanele ukukhiqizwa okukhulu.

| Ukucaciswa Kwedizayini / I-Cost Factor | I-Single Screw Extruder Characters |

|---|---|

| Ubulula Kudizayini | Izingxenye ezihambayo ezimbalwa, kulula ukuzisebenza nokuzinakekela |

| Imali Enkulu Nezindleko Zokusebenza | Izindleko eziphansi zokutshala izimali kanye nokugcinwa kwazo |

| Ukusebenza Kwamandla | Isebenzisa amandla amancane ukwenza imisebenzi elula |

| Isondlo | Ukuqaqa ngokushesha nokuhlanza |

| Okokusebenza | Iphakeme ngezinto ezilula |

Ukugeleza Okubalulekile kanye Nokuxuba Indlela

Ukugeleza kwezinto ku-twin screw extruder kubandakanya ukugeleza kokudonsa, ukugeleza kwengcindezi, nokugeleza kokuvuza. Izikulufu ezihlanganisayo zenza ukushear nokuxova imiphumela, okuthuthukisa ukuxuba nokuhlakazeka okungeziwe. Izikulufu ezijikelezayo zithuthukisa ukusebenza kahle kokuxuba futhi zisize ukuphatha ukushisa, zehlise ubungozi bokuwohloka kwezinto. Ngokuphambene, ama-extruder wesikulufu esisodwa ancike kakhulu ekugelezeni kokuhudula, okukhawulela amandla okuxuba kodwa okuqinisekisa ukukhishwa okuzinzile kwezinto ezilula. I-Screw geometry, isivinini, kanye ne-viscosity yezinto ezibonakalayo konke kuthonya ukuhamba nokusebenza kokuxuba.

I-Degassing kanye nezici zokuzihlanza

Ama-twin screw extruder ahamba phambili ekususeni umoya ngoba izikulufu ezihlanganayo zikhulisa indawo engaphezulu ukuze kukhishwe igesi. Amanye amasistimu akhulisa ukusebenza kokukhipha umoya ngokufika ku-500% uma kuqhathaniswa nemiklamo yesikulufu esisodwa. Izici zokuzihlanza, ezifana nesenzo sesikulufu sokuzisula, zisiza ukugcina ukuhambisana kwenqubo nokunciphisa isikhathi sokuphumula. Amasistimu okuhlunga athuthukile kanye nokulawula okunembile kwemingcele ye-extrusion kusekela futhi lezi zinzuzo. Ama-extruder angama-screw single anikezela ngokuhlanza okuqondile ngenxa yokwakhiwa kwawo okulula, kodwa akufani nokusebenza kahle kokususa ugesi kwamasistimu ngezikulufu ezingamawele.

Ukuqhathanisa Ukusebenza

Ukuxuba Ikhono kanye Homogeneity

Ikhwalithi yokuxuba ime njengento echazayo ekusebenzeni kwe-extrusion. Ama-twin screw extruder aletha ukuxubana okuphezulu ngenxa yezikulufu zazo ezimbili ezihlanganayo. Lezi zikulufu zihlakaza futhi zisabalalise izithasiselo kahle, zikhiqize ukuncibilika okufana kakhulu. Indlela yokuzisula phakathi kwezikulufu ivimbela ukwakheka kwezinto futhi iqinisekisa ukuxubana okuphelele. Ezifundweni ezilawulwayo, ama-twin screw extruder akhiqize izingxube ezomile zokuhogela impushana ngehlanganisa ukufana nokusebenza kwe-aerosolelilingana noma elingcono kunokuxuba inqwaba ye-shear ephezulu. Abacwaningi bathole ukuthi amapharamitha okucubungula afana nesivinini sesikulufa kanye nezinga lokuphakelayo akuzange kuthinte kakhulu ukuvumelana komkhiqizo wokugcina. Lokhu kuqina kuvumela abakhiqizi ukuthi bazuze izingxube ezifanayo kanye nekhwalithi yomkhiqizo engaguquki, ngisho nokubunjwa okuyinkimbinkimbi.

Ama-twin screw extruder avumela ukwenziwa ngendlela oyifisayo kwamandla okuxuba ngokulungisa amaphrofayili ngezikulufu nezinto. Lokhu kuvumelana nezimo kuvumela ukulungiselelwa kwezinto ezithile nezinhlelo zokusebenza, okuholela ekuhlakazweni okuthuthukisiwe kanye nokufana kwenhlanganisela.

Ukungaguquguquki Kokukhiphayo

Ukungaguquguquki kokusebenza nokuphumayo kubalulekile ekukhiqizweni kwezimboni. Ama-extruder ama-twin screw ayazuzaamazinga okuphuma aphezulufuthi zicubungule izinto ngokuphumelelayo kunamamodeli ayisikulufu esisodwa. Bagcina ukulawulwa kwenqubo okunembayo, okuholela kwikhwalithi yomkhiqizo engaguquki kanye namaphutha ambalwa. Ithebula elingezansi lifingqa umehluko oyinhloko:

| Uhlobo lwe-Extruder | Izimpawu Zokusebenzisa | Izimpawu Zokuvumelana Komphumela |

|---|---|---|

| I-twin screw extruder | Ukusebenza okuphezulu; ukucubungula kahle; ukonga amandla | Ukulawulwa kwenqubo okunembe; ukuxuba okuphezulu; izinga lomkhiqizo elingaguquki; amaphutha ambalwa kanye nokumosha okuncane |

| I-scruder yesikulufu esisodwa | Ukusebenza okulingene; elula futhi engabizi | Izinselele zokungaguquguquki kwengcindezi; ikhono elilinganiselwe lokuhlanganisa; amathuba okusatshalaliswa kwezinto ezingalingani kanye nokukhubazeka kwemikhiqizo |

Ama-extruder wesikulufu esisodwa angase abe nokuguquguquka kwengcindezi kanye nemikhawulo yokugeleza kwezinto, okungaba nomthelela ekufanisweni kokuphumayo. Ngakolunye uhlangothi, ama-twin screw extruder, ahlinzeka ngokusebenza okuzinzile nemiphumela ethembekile, okuwenza alungele ukukhiqizwa kwenani elikhulu.

Ukuphatha Izinto kanye Nokuvumelana nezimo

Ukuphatha impahla kanye nokuguquguquka kunquma ukuthi i-extruder ijwayelana kahle kangakanani nezinto zokusetshenziswa ezahlukene kanye nokwakheka. Ama-twin screw extruder ahamba phambili ekucubunguleni izimpushana, izinto okunzima ukuziphakela, nezingxube eziyinkimbinkimbi. Banikeza ukuxubana okuhlakazekayo okuphakeme nokusabalalisa, ukuphatha ububanzi be-viscosity, futhi bafake izithasiselo eziningi kalula. Ithebula elingezansi ligqamisa lokhu kwehluka:

| Isici | I-Single Screw Extruder | I-Twin Screw Extruder |

|---|---|---|

| Ifomu Lempahla | Kuhle kakhulu kuma-pellets nama-granules | Kungcono kuma-powder nezinto okunzima ukuzondla |

| Ikhono Lokuxuba | Kukhawulelwe ekuxubeni kokusabalalisa | Ukuxuba okuphezulu kwe-dispersive nokusabalalisa |

| Ukuzwela Kokushisa | Isikhathi eside sokuhlala | Isikhathi sokuhlala esifushane, esilawulwa kakhulu |

| I-Additive Incorporation | Ukufakwa okuyisisekelo okungeziwe | Iphatha ukwakheka okuyinkimbinkimbi ngezithasiselo eziningi |

| I-Viscosity Range | Ibanga elinomkhawulo | Ububanzi be-viscosity ububanzi |

Ama-twin screw extruder aphinde anikeze ukulawula kwenqubo okuthuthukisiwe, okuhlanganisa ukulawulwa okunembile kwezinga lokushisa kanye nezikhathi zokuhlala ezimfushane. Lezi zici zizuzisa izinto ezizwela ukushisa nezindlela zokupheka eziyinkimbinkimbi. Ama-extruder angama-screw single ahlala ebiza futhi ethembekile kuma-pellets afanayo kodwa awanakho ukuguquguquka futhiamakhono okuhlanganisa athuthukileama-twin screw systems.

Ukusebenza Kwe-Degassing

I-Degassing isusa amagesi avaleleke kanye nomswakama ezintweni ngesikhathi sokukhipha. Ama-twin screw extruder anikeza ukusebenza kahle okuhle kakhulu kokususa ugesi ngenxa yedizayini yesikulufu esihlanganayo, esikhulisa indawo engaphezulu ukuze kukhishwe igesi. Lesi sici sibonakala sibalulekile ezinhlelweni zokusebenza ezidinga ukuhlanzeka okuphezulu komkhiqizo noma lapho ukucubungula izinto ezijwayele ukwakheka kwegesi. I-degassing ethuthukisiwe iholela ekulimaleni okumbalwa kanye nekhwalithi yomkhiqizo ethuthukisiwe. Ama-extruder angama-screw extruder ahlinzeka ngokususa ugesi okuyisisekelo kodwa awakwazi ukufana nokusebenza kahle kwama-twin screw extruder ezinhlelweni ezifunayo.

Ukuzihlanza Nokunakekela

Izici zokuzihlanza zinciphisa isikhathi futhi zenze ukulungiswa kube lula. Ama-twin screw extruder asebenzisa isenzo sesikulufu sokuzisula ukuvimbela ukwakheka kwezinto kanye nokusekela ukusebenza okuqhubekayo. Idatha yokuhlola ibonisa ukuthi ukulungisa amapharamitha e-extruder afana nobubanzi nokuphakama kwesendlalelo kungathuthukisa ukuhwayela nokumanzisa kwendawo, kuthuthukise ukusebenza kokuzihlanza. Izinto ezifana nama-thermoplastic elastomers akhombisa izinombolo eziphakeme zokuzihlanza, okuhumushela ekuhlanzeni okumbalwa okwenziwa ngesandla kanye nezindleko zokunakekela eziphansi. Ama-extruder angama-screw single kulula ukuwahlakaza futhi ahlanzeke ngenxa yedizayini yawo elula, kodwa awanikezi izinga elifanayo lokuzihlanza okuzenzakalelayo njengamasistimu ngezikulufu ezingamawele.

Ukunakekelwa okuvamile kanye nezilungiselelo ze-extruder ezithuthukisiwe zisiza ukugcina ukusebenza okuphezulu kanye nokwelula impilo yesisetshenziswa.

Ukufaneleka Kohlelo

Izicelo zePlastiki Twin Screw Extruder

A plastic twin screw extruderisebenzela izinhlobonhlobo zezimboni ezidinga ukuxubana okuthuthukile, ukulawula okunembayo, nokuguquguquka. Abakhiqizi basebenzisa le mishini ukuhlanganisa, ukukhiqizwa kwe-masterbatch, ukuhlanganisa i-polymer, nokucubungula amapulasitiki agaywe kabusha. Idizayini ye-modular ivumela onjiniyela ukuthi balungise amaphrofayili wesikulufa wezinto ezithile, bathuthukise ukusebenza kahle kanye nekhwalithi yomkhiqizo. Izinkampani ezisemikhakheni yezimoto nezokwakha zithembele kuma-twin screw extruder ukuze uthole izingxenye ezisebenza kahle kakhulu. Imibiko yobuchwepheshe igqamisa ukuthuthukiswa kokusebenza kahle kokukhiqiza kanye nekhwalithi yefomula, ikakhulukazi ezinhlelweni ezifana nokuguqulwa kwepulasitiki yobunjiniyela nokucutshungulwa kwezinto ezigaywe kabusha. Imakethe ye-extruder barrel iyaqhubeka nokuvela, ngokwanda kokwamukelwa kwama-extruder angamawele kanye ne-multi-screw emikhakheni enevolumu ephezulu nedinga ukunemba efana nemithi kanye nokucubungula ukudla.

Ukusetshenziswa Okungcono Kakhulu Kwe-Single Screw Extruder

Ama-extruder wesikulufu esisodwahlala kuyisinqumo esikhethwayo semisebenzi elula, ephezulu yokukhiqiza. Le mishini iphumelela kakhulu ekukhiqizeni imikhiqizo enezingxube ezingashintshi, ezomile, njenge-pasta, ukudla okuyisisekelo kwezilwane ezifuywayo, nokudla okulula okusekelwe elayisi. Umklamo wabo oqondile uqinisekisa ukugcinwa okuphansi kanye nezindleko zokusebenza. Ithebula elingezansi lifingqa izimo ezingcono kakhulu zokusebenzisa:

| Uhlobo Lomkhiqizo | Uhlobo Lwe-Extrusion Olukhethwayo | Ukubonisana |

|---|---|---|

| I-Pasta | Isikulufa Esisodwa | Ukwakheka okulula okomile, ukuxuba okuncane |

| Ukudla Kwezilwane Eziyisisekelo | I-Single noma i-Twin Screw | Zombili ziyasebenza, isikulufa esisodwa siyabiza |

| I-Puffed Rice Snacks | Isikulufa Esisodwa | Okokufaka okomile okungaguquki, ukuphuma okuphezulu |

Umkhiqizi wokudla okulula okhiqiza amabhola elayisi akhukhumele uthole ama-extruder angama-screw single alungele izindlela zokupheka ezilula. Kodwa-ke, lapho beshintshela emikhiqizweni ye-multigrain, bebedinga i-twin screw extruder ukuze kuxutshwe kangcono nokuncipha kwemfucuza.

Izibonelo Zemboni

- Izinkampani zokudla ezifana ne-Nestlé kanye ne-Kellogg zitshala imali emishinini yokukhiqiza ukuze kuhlangatshezwane nesidingo esikhulayo sokudla okugayiwe.

- Imikhakha yezokwakha neyezimoto incike ezingxenyeni ezinwetshiwe, amafemu afana ne-Bausano kanye ne-KraussMaffei ehlinzeka ngezixazululo ezihambisanayo.

- Ukukhiqiza okungeziwe kuhlanganisa ne-extrusion yokukhiqiza okwenziwe ngokwezifiso, njengoba kubonakala ku-CEAD ne-Arburg.

- Amathrendi okulawula kanye nendawo ezungezile aqhuba ukwamukelwa kwemishini yokukhipha eyonga amandla, ne-biodegradable-compatible extrusion.

Izindlela ezintsha zobuchwepheshe, ezihlanganisa i-automation kanye nokuxhumana kwe-IoT, ziyaqhubeka nokuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo kuzo zonke izimboni.

Ukucatshangelwa kokusebenza

Ukusetshenziswa Kalula Nokuqeqeshwa

Ama-opharetha athola amasistimu e-extruder esimanje asebenziseka kalula ngenxa yezindawo zokulawula ezithuthukile. Lawa masistimu abonisa idatha yesikhathi sangempela, ama-alamu, nokubuka konke kwezithombe, okusiza opharetha baqaphele futhi balungise inqubo ngokushesha. Izidingo zokuqeqesha zincike ohlotsheni lwe-extruder. Ama-extruder ngesikulufu esisodwa anomklamo oqondile, ngakho o-opharetha abasha bangafunda ukusebenza okuyisisekelo nokuxazulula izinkinga ngesikhathi esifushane.Ama-extruder ama-twin screwnikeza izici ezengeziwe, ezifana nokuphathwa kweresiphi nokuxazulula inkinga okukude, okudinga ukuqeqeshwa okwengeziwe. Amasistimu okulawula anamalogu emicimbi kanye nokuqoqwa kwedatha asiza opharetha ukuthi baphendule ekucubunguleni izinguquko futhi bagcine ikhwalithi yomkhiqizo.

Ithiphu: Ukutshala imali ekuqeqeshweni komsebenzisi kuthuthukisa ukuzinza kwenqubo futhi kunciphisa ubungozi bamaphutha.

Isondlo kanye Nesikhathi Sokuphumula

Ukunakekelwa okuvamile kugcina ama-extruder asebenza kahle futhi andisa ukuphila kwawo. Amashejuli okulungisa ayahluka phakathi kwesikulufa esisodwa nezikulufa ezingamawele ezingamawele. Ithebula elingezansi ligqamisa izindawo okugxilwe kuzo ezibalulekile:

| Uhlobo lwe-Extruder | I-Maintainance Focus Areas | Hlela Amaphuzu Avelele |

|---|---|---|

| Isikulufa Esisodwa | Okuphakelayo ukupholisa umphimbo, ukuguga kwesikulufu/umgqomo, isheke le-thrust bear | Uwoyela ushintsha njalo ngamahora angu-4,000-5,000 |

| I-Twin Screw | Ukuqondanisa isikulufu, ukusatshalaliswa kwetorque, ukuhlolwa kwesegimenti yomgqomo | Isistimu yokupholisa ihlanzwa njalo ezinyangeni eziyisithupha |

Amarekhodi okulondoloza alandelela ukuhlolwa, ukulungiswa, nokushintshwa kwezingxenye. Lawa marekhodi asiza amaqembu ukuthi abone izinkinga eziqhubekayo futhi ahlele ukunakekelwa kokuzivikela. Ukugcinwa okuvimbelayo cannciphisa isikhathi sokuphumula kuze kufike ku-45%futhi wengeze iminyaka empilweni yemishini.

- Amalogi okulondoloza asekela ukuxazulula izinkinga nokuhlela okusebenzayo.

- Ukunganaki amarekhodi kuholela ekwehleni okude kanye nokulungiswa okuphindaphindiwe.

Izindleko kanye Nembuyiselo Kutshalomali

Izindleko nembuyiselo ku-investimenti (ROI) idlala indima enkulu ekukhetheni i-extruder. Ukubunjwa kwe-Extrusion ngokuvamile kudinga aukutshalwa kwezimali kokuqala okuphansikunezinye izindlela, njengokubumba umjovo. Izinhlelo ezizenzakalelayo zinciphisa izindleko zabasebenzi kanye nokuchithwa kwezinto ezibonakalayo, okwenza ngcono ukusebenza kahle kokukhiqiza. Ukusebenza okuqhubekayo futhi kwehlisa isikhathi sokuphumula, okuthuthukisa i-ROI kumaphrojekthi wevolumu ephezulu. Izinkampani zivame ukukhetha i-extrusion yezingxenye ezilula ukuze kwandiswe ukonga izindleko, kuyilapho izingxenye eziyinkimbinkimbi, ezinembayo eziphezulu zingathethelela izindleko eziphezulu zangaphambili kwezinye izinqubo. Ukuhlolwa ngokucophelela kwezindleko zemishini, ukusetshenziswa kwezinto ezibonakalayo, nezidingo zabasebenzi kuqinisekisa inani elingcono kakhulu lesikhathi eside.

Umhlahlandlela Wesinqumo

Ukukhetha Ngokusekelwe Ezidingweni Zokusebenza

Ukukhetha isistimu ye-extruder efanele kuncike ekubuyekezweni ngokucophelela kwezidingo zokusebenza. Abakhiqizi abaningi basebenzisaizinhlaka zokuthatha izinqumoezihlanganisa ukuhlaziywa kwe-techno-economic, amamodeli okulinganisa izindleko, namathuluzi asizwa nge-AI. Lezi zinhlaka zisiza abasebenzisi ukuqhathanisa izinketho ezisuselwa kuzindleko, isikhathi sokwakha, izakhiwo zezinto ezibonakalayo, kanye nezidingo eziqondene nomkhakha othile. Izindlela zokwenza izinqumo zemibandela eminingi, njenge-AHP, TOPSIS, ne-VIKOR, zivumela amaqembu ukuthi ahlole kokubili izici zobuningi nekhwalithi. Ama-chatbots e-AI asebenzayo manje ahlinzeka ngolwazi olufanelana nawe, oludonsa kudathabhethi enkulu yocwaningo ukusekela ukukhetha okunolwazi. Ucwaningo lwezehlakalo lubonisa ukuthi le ndlela ithuthukisa ukunemba kwesinqumo, ngezilinganiso zezindleko ezicishe zifane nezingcaphuno zomhlaba wangempela zezingxenye ezihlukahlukene. Inqubo inika abasebenzisi amandla okwenza izinqumo ezizimele ngokwethula idatha ebanzi, kunokuphoqelela isisombululo esisodwa.

Ithiphu: Sebenzisa amathuluzi asebenzisanayo nezifundo eziyizimo ukuze uqhathanise ukusebenza, izindleko, nokuhambisana kwezinto ngaphambi kokwenza ukukhetha kokugcina.

Imibuzo Ebalulekile Okufanele Uyicabangele

Lapho ukhetha phakathi kwe-aIsikulufu esisodwa noma i-twin screw extruder, amaqembu kufanele abuyekeze ezininganaizici zemishini nezokusebenza:

- Yimaphi amandla okushayela namandla aphikisayo abandakanyekayo enqubweni ye-extrusion?

- Iyiphi indlela ye-extrusion elingana kahle nohlelo lokusebenza?

- Ngabe ukwakheka kwegumbi kuyithinta kanjani ingcindezi ye-extrusion nokugeleza?

- Ikuphi ukucushwa kwe-outlet kuzothuthukisa ikhwalithi yomkhiqizo?

- Ingabe izici ezithuthukisiwe ezifana nokuxubana kwesibili noma ukuqinisa kuyadingeka?

- Izakhiwo zezinto ezibonakalayo kanye nemingcele yokusebenza zisebenzisana kanjani?

| Ukucabangela | I-Single Screw Extruder | I-Twin Screw Extruder |

|---|---|---|

| Ukuvumelana nezimo | Iguquguquka kancane, kulula ukuyisebenzisa nokuyinakekela | Ivumelana nezimo kakhudlwana, isekela ukuhlukahluka kokwakheka okubanzi |

| Izindleko Zokuqala | Izindleko eziphansi zokuthenga | Ukutshalwa kwezimali kokuqala okuphezulu |

| Izindleko Zokusebenza | Ukusetshenziswa kwamandla okuphansi kanye nezindleko zokuyigcina | Izindleko eziphezulu zokusebenza nezokulungisa |

| Ukukhiqiza Ngempumelelo | Ukulawula okulula, ubunzima obuphansi, okukhiphayo okuphansi | Ukusebenza okuphezulu, ukuxuba okungcono, ikhwalithi yomkhiqizo ethuthukisiwe |

| Ukuhambisana Kwezinto ezibonakalayo | Ifanele inhlobonhlobo yezinto zokwakha | Kungcono ngezinqubo eziyinkimbinkimbi kanye nokwakheka okuthuthukile |

Ochwepheshe bemboni batusa ukuhlaziya imigomo yokukhiqiza, izindleko eziphelele, nezimfuneko zezinto ezibonakalayo. Ukubonisana nochwepheshe kungasiza ukuqinisekisa ukuthi i-extruder ekhethiwe ihlangabezana nezidingo zamanje nezesikhathi esizayo.

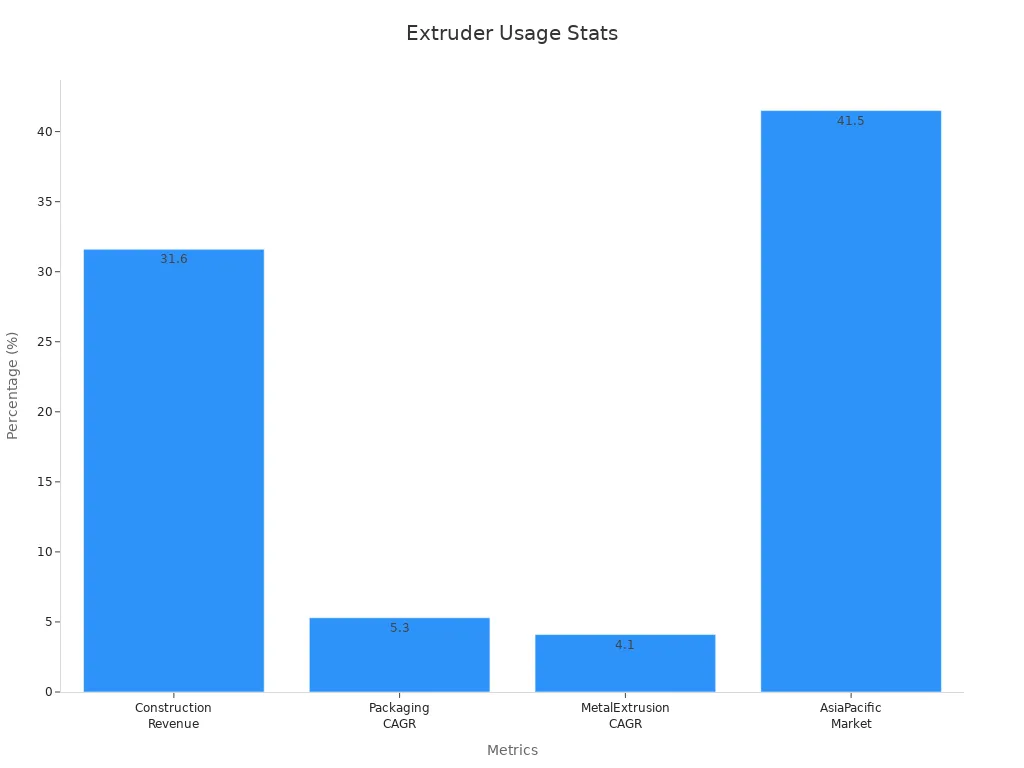

Ubuchwepheshe be-twin screw extruderisekela ukuxubana okuthuthukile nokuguquguquka kokucubungula kwepulasitiki okuyinkimbinkimbi. Ama-extruder screw single ahlala elungele imisebenzi elula, enevolumu ephezulu. Idatha yemakethe ikhombisa i-CAGR engu-6% eqagelayo yama-screw extruder angamawele, ekhombisa isidingo esinamandla kanye nokufaneleka okubanzi kwezimboni.

| Isici | I-Trend/Implication |

|---|---|

| I-CAGR yemakethe | ~6% (2024-2033) |

| Izicelo Zemboni | Ipulasitiki, ukudla, imithi, amakhemikhali |

| Ingxenye Yomkhiqizo | Ama-extruder angamawele ajikelezayo aholela ekukhuleni |

FAQ

Yiziphi izinto ezingenza inqubo ye-plastic twin screw extruder?

A plastic twin screw extruderiphatha i-polyethylene, i-polypropylene, i-PVC, i-ABS, namapulasitiki obunjiniyela. Isekela ukuhlanganiswa, ukuxuba, kanye nokukhiqizwa kwe-masterbatch ezimbonini ezihlukahlukene.

Ingabe i-twin screw extruder ithuthukisa kanjani ukuxubana uma iqhathaniswa ne-screw extruder eyodwa?

Ama-twin screw extruder asebenzisa izikulufu ezihlanganayo. Lezi zikulufu zidala ukugunda okuqinile namandla okuxova. Lesi senzo siqinisekisa ukuhlakazeka okungcono kwesengezo kanye nomkhiqizo ofanayo.

Ingabe i-twin screw extruder machine ifanele amapulasitiki agaywe kabusha?

Yebo. Inqubo yemishini yokukhipha izikulufu ezimbiliamapulasitiki agaywe kabushangempumelelo. Banikeza ukulawulwa kwezinga lokushisa okunembile kanye nokuxuba okuthuthukile, okuthuthukisa ikhwalithi yokuphuma kwezinto ezigaywe kabusha.

Isikhathi sokuthumela: Jun-26-2025