Ukukhetha ama-twin screw plastic extruder alungile kuqinisekisa ukusebenza kahle nokunemba ezinqubweni zokubumba umjovo. Le mishini ithuthukisa ukuxubana kwezinto, ithuthukise umthamo, futhi yandise amandla okucubungula, iyenze ibaluleke kakhulu ekukhiqizweni kwevolumu ephezulu.

- Imakethe yomhlaba wonke ye-screw extruder, enenani elingu-USD 1,128.1 million ngo-2022, kulindeleke ukuthi ifinyelele ku-USD 1,649.5 million ngo-2031.

- Izinga lokukhula lonyaka elingu-4.5% ligqamisa isidingo sabo esikhulayo kuzo zonke izimboni.

- Imiklamo ethuthukisiwe, njengeama-twin-screw extruder screw imiphongolo, thuthukisa ukusebenza nokuthembeka.

Ukuhambisana, ukwenza ngokwezifiso, kanye nokusebenza ngempumelelo kwezindleko kuhlala kuyizici ezibalulekile lapho kukhethwa aisikulufa esiphindwe kabilingezicelo ezithile, ikakhulukazi uma kucutshungulwa aumshini we-screw extruder ophindwe kabiliyakhelwe ukuhlangabezana nezidingo eziyingqayizivele zokukhiqiza.

Ukubaluleka kwama-Twin Screw Plastic Extruders

Izinzuzo Zokubumba Umjovo

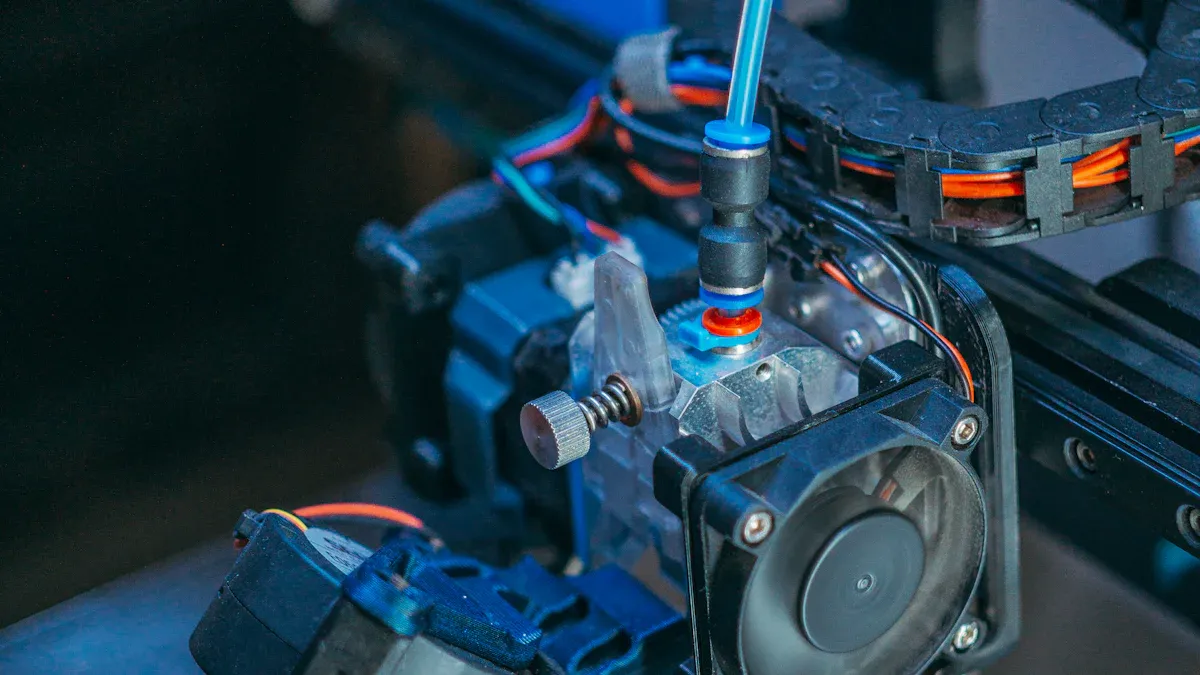

Ama-extruder epulasitiki ama-twin screw adlala indima ebalulekileiqhaza ekuthuthukiseni ukusebenza kahlekanye nekhwalithi yezinqubo zokubumba umjovo. Idizayini yabo ethuthukisiwe inika amandla ukulawula okunembile kokuhlanganisa, ukubola, nokuxubana, okubalulekile ekukhiqizeni izingxenye ezibunjiwe zekhwalithi ephezulu. Ngokuphatha ingcindezi ngempumelelo, le mishini igcina izinga lokushisa elilungile lokuncibilika kanye ne-viscosity, iqinisekisa ukusebenza komkhiqizo okungaguquki.

Izinzuzo ezibalulekile zifaka:

- Ukushintsha izimboni kusuka kunqwaba kuya ekuqhubekiseni okuqhubekayo, kuthuthukisa kakhulu ukusebenza kahle.

- Ukwenza ngendlela oyifisayo izakhiwo zezinto ezibonakalayo ngokusebenzisa amandla aphezulu okuhlanganisa, okuthinta ngokuqondile ikhwalithi yomkhiqizo.

- Ukwenza lula ukubhidliza amandla ngamapayipi abekwe kahle, ukuvimbela izikhukhula kanye nokuqinisekisa ukususwa kwezimo eziguquguqukayo.

- Ukuvumela ukulawula okuzimele kwamazinga okuphakelayo kanye nama-RPM wesikulufu, kuthuthukisa izinqubo zokuhlanganisa kanye ne-devolatilization.

Idizayini ejikelezayo, ehlanganayo yama-twin screw plastic extruder ithathwa kabanzi njengesixazululo esisebenza kahle kakhulu sokuhlanganisa embonini yepulasitiki. Lokhu kubenza babaluleke kakhulu kubakhiqizi abafuna ukuthola ukunemba nokuthembeka ekubumbeni umjovo.

Izinzuzo Over Single Isikulufa Extruder

Ama-extruder epulasitiki angama-twin screw anikezela ngezinzuzo ezimbalwa ngaphezu kozakwabo abayizikulufu abangabodwa, ikakhulukazi ngokuya ngamakhono okucubungula, ukuguquguquka, nokusebenza kahle. Ithebula elilandelayo ligqamisa umehluko oyinhloko:

| Isici | I-Single Screw Extruder | I-Twin Screw Extruder |

|---|---|---|

| Amakhono Okucubungula | I-extrusion eyisisekelo kanye nokuhlanganisa okulula. | Iphatha izinto eziyinkimbinkimbi kanye nokuxuba okuyinkimbinkimbi. |

| Ukuphumelela kanye Nempumelelo | Ukukhiqiza okuphansi, kulungele ukukhiqizwa kwezinga elincane. | Ukusebenza okuphezulu, okuqinisekisa ikhwalithi yomkhiqizo engcono. |

| Ukuguquguquka nokuguquguquka | Ukuvumelana nezimo okulinganiselwe, ukusebenza okulula. | Ivumelana nezimo kakhulu ngamapharamitha alungisekayo. |

| I-Material Flexibility | Ifanele ama-thermoplastics ayisisekelo nama-filler. | Ilungele ukwakheka okuyinkimbinkimbi kanye nezinto ezisezingeni eliphezulu ze-viscosity. |

| Ukuxuba Amandla | Kwanele ukwakheka okulula. | Ukuxuba okuphezulu, kuphelele ekuhlanganisweni okungeziwe. |

| I-Degassing kanye ne-Devolatilization | Amandla anomkhawulo. | Amandla amahle kakhulu, ahlangabezana nezindinganiso eziqinile zekhwalithi. |

Lezi zinzuzo zenza ama-twin screw plastic extruder abe yinketho ekhethwayo yabakhiqizi abahlose ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo. Ikhono labo lokuphatha izinto ezihlukahlukene kanye nokwakheka okuyinkimbinkimbi kuqinisekisa ukuthi bahlala beyisisekelo sezinqubo zesimanje zokubumba umjovo.

Izinto Ezibalulekile Okufanele Uzicabange Lapho Ukhetha Ama-Twin Screw Plastic Extruder

Ukuhambisana Nemishini Yokubumba Yokujova

Ukukhetha i-twin screw plastic extruder eqondana nezicaciso zomshini wakho wokubumba umjovo kubalulekile. Ukuhambisana kuqinisekisa ukuhlanganiswa okungenamthungo, kunciphisa isikhathi sokuphumula nokuthuthukisa ukusebenza kahle okuphelele. Abakhiqizi kufanele bahlole umthamo wokukhiphayo we-extruder, idizayini yesikulufu, namandla okubamba okubalulekile ukuze kufane nezidingo zemishini yabo yokubumba. Isibonelo, i-extruder ene-torque ephezulu nesivinini se-screw ingaphatha izinto eziyinkimbinkimbi, iqinisekisa ukuphakela okungaguquki kanye nezinqubo zokuncibilika.

I-extruder efaniswe kahle iphinde inciphise ukusetshenziswa kwamandla nokuguga ezingxenyeni. Ithebula elilandelayo ligqamisa ukuthi izici ezibalulekile ezifana nesivinini sesikulufa kanye nezakhiwo zezinto ezibonakalayo zikuthinta kanjani ukusebenza:

| Isici Esibalulekile | Umthelela Ekusetshenzisweni Kwamandla | Umthelela Kungcindezi | Umthelela ku-Torque |

|---|---|---|---|

| Isivinini sokuzungeza isikulufu (n) | Ukwehliswa okukhulu ekusetshenzisweni kwamandla okuqondile (ukuncipha okungama-45%) ngesivinini esithe xaxa | Ingcindezi eyengeziwe ngo-3.1 MPa (65%) ngesivinini esiphezulu | I-torque eyengeziwe enesivinini esiphezulu |

| Okuqukethwe kwegatsha (u) | Awukho umthelela obalulekile ekusetshenzisweni kwamandla | Ingcindezi eyengeziwe ngo-3.8 MPa (75%) enokuqukethwe okuncishisiwe kwe-bran | I-torque yehle ngo-34% ngokuqukethwe kwe-bran eyengeziwe |

Ukuqonda lawa mamethrikhi kusiza abakhiqizi ukuthi bakhethe i-extruder ehambisana nokusetha kwabo komjovo.

Izinketho zokwenza ngokwezifiso zezinhlelo zokusebenza ezithize

Ama-extruder epulasitiki angama-twin screw anikezela ngezinketho zokwenza ngokwezifiso ezingenakuqhathaniswa, ezizenza zilungele izinhlelo zokusebenza ezahlukahlukene. Le mishini ivumela abakhiqizi ukuthi bahlanganise imiklamo yesikulufu ukuze ihambisane nokusebenza kweyunithi ethile, njengokuxuba, ukuqeda amandla, noma ukuhlanganisa. Isici ngasinye sesikulufa sisebenzela injongo ehlukile, futhi ukulungiswa okuncane kungase kube nomthelela omkhulu emiphumeleni yokucubungula izinto.

Izici ezibalulekile zokwenza ngokwezifiso zifaka:

- Ukulungiselelwa kwesikulufu esivumelana nezimo ukuze kuthuthukiswe ukuxubana nokugeleza kwempahla.

- Izigaba zemiphongolo ehlelwa kabusha ukuze kuthuthukiswe inqubo yokukhipha ngaphandle kokulungiswa okubanzi.

Leli zinga lokuvumelana nezimo liqinisekisa ukuthi abakhiqizi bangahlangabezana nezidingo ezihlukile zokukhiqiza kuyilapho begcina izindleko zisebenza kahle. Isibonelo, izimboni ezidinga okokusebenza kwe-viscosity ephezulu noma ukwakheka okuyinkimbinkimbi kuyazuza kulezi zici ezingenziwa ngendlela oyifisayo.

Amamethrikhi okusebenza: I-torque, isivinini, kanye nokuphuma kwezinto ezibonakalayo

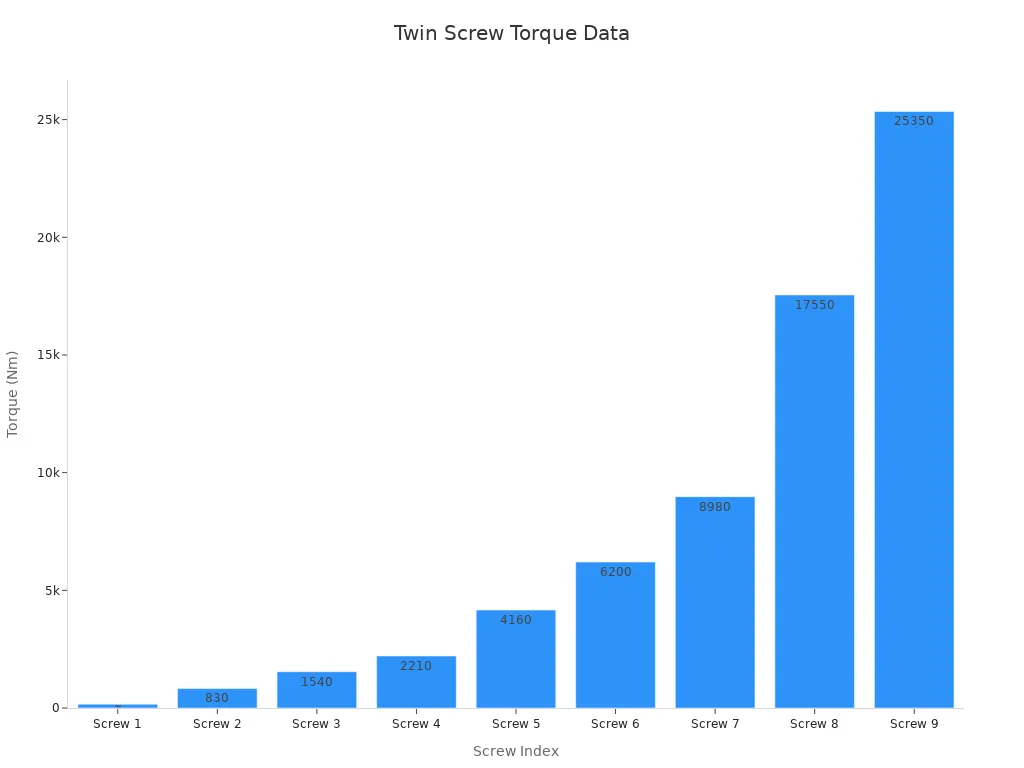

Amamethrikhi okusebenza adlala indima ebalulekile ekunqumeni ukusebenza kahle kwama-twin screw plastic extruder.Ukuminyana kwe-torque, isivinini se-screw, kanye nokuphuma kwezinto ezibonakalayo kuyimingcele ebalulekile ethonya ikhono lomshini lokucubungula izinto ngokuphumelelayo. Ukuminyana kwetorque ephezulu, ngokwesibonelo, kuvumela i-extruder ukuthi ibambe izinhlelo zokusebenza ezinzima, njengokuhlanganisa ama-polymer aqinisiwe noma ukucubungula izinto ezine-viscosity ephezulu.

Ithebula elingezansi linikeza isifinyezo sedatha yokusebenza kwama-twin screw extruder:

| Ipharamitha | Inani |

|---|---|

| I-Torque Density | Amandla aphezulu afika ku-18 Nm/cm³ |

| I-Torque kusikulufa ngasinye (Nm) | 160, 830, 1540, 2210, 4160, 6200, 8980, 17550, 25350 |

| Isivinini seScrew (rpm) | 1200 kumamodeli amaningi, amanye angu-500 |

| I-Material throughput | Amandla angu-2,700 kg/h ku-PP+glass fiber application |

Lawa mamethrikhi agqamisa ukusebenza okuphakeme kwama-twin screw extruder uma kuqhathaniswa namazinga omkhakha, okuwenza abe yinketho ethembekile yokukhiqiza ivolumu ephezulu.

Izindleko Nesabelomali

Izindleko ziyisici esibalulekile lapho ukhetha i-twin screw plastic extruder. Abakhiqizi kufanele balinganisele izindleko zokuqala zokutshala imali nokusebenza kahle kwesikhathi eside. Nakuba ama-extruder asebenza kahle kakhulu angase abe nezindleko eziphezulu zangaphambili, ukusebenza kahle kwawo kwamandla, ukuqina, kanye nezidingo ezincishisiwe zokulungiswa ngokuvamile kuholela ezindlekweni eziphelele zobunikazi.

Izinto ezinomthelela wezindleko zifaka:

- Isikulufu kanye nekhwalithi yempahla yomgqomo.

- Izidingo zokwenza ngokwezifiso.

- Izici ezithuthukisiwe njengezilawuli ezizenzakalelayo namasistimu okuqapha.

Ukutshala imali ku-extruder yekhwalithi ephezulu evela kumkhiqizi ohloniphekile kuqinisekisa ukusebenza okungcono nokutholakala kwezingxenye ezisele, kunciphisa isikhathi sokuphumula kanye nezindleko zokulungisa.

Ukwethenjelwa kanye Nezimfuneko Zokugcina

Ukwethembeka kubalulekile ekugcineni ikhwalithi yokukhiqiza engaguquki. Ama-extruder epulasitiki angama-twin screw anezici zekhwalithi ephezulu, njengezikulufi, imiphongolo, namabhokisi ogiya, anikeza ukuqina nokusebenza okungcono. Ukunakekelwa okuvamile kubalulekile ngokufanayo ukuvimbela ukwehluleka kwemishini nokwelula isikhathi sokuphila somshini.

Izinqubo zokunakekela ezibalulekile zihlanganisa:

- Ukuqapha amapharamitha enqubo ukuze kuhlonzwe izinkinga ezingaba khona kusenesikhathi.

- Ukuqalisa izinhlelo zokulungisa zokuvikela ukunciphisa ukuguga.

- Ukuqeqesha abasebenzi ukuthi babone amaphethini kumajika athrendayo ukuze baxazulule inkinga.

Izikulufu ze-Extruder nemiphongolo ziyaguga ngokuhamba kwesikhathi, okungase kuthinte amazinga okukhiphayo kanye namazinga okushisa okukhipha. Abakhiqizi kufanele bacabangele imithelela yezomnotho yokushintsha izinto ezigugile ukuze kugcinwe inzuzo. Ukukhetha i-extruder ethembekile kunciphisa lezi zinselele, kuqinisekisa impumelelo yokusebenza yesikhathi eside.

Ukuhlola Abakhiqizi Nabahlinzeki Bempahla

Imibandela Yokukhetha Umkhiqizi Ohloniphekile

Ukukhetha umkhiqizi olungileama-twin screw plastic extruder kubalulekile ekuqinisekiseni impumelelo yesikhathi eside emisebenzini yokubumba umjovo. Abakhiqizi abahloniphekile babonisa ukuzibophezela ekusunguleni izinto ezintsha, ikhwalithi, kanye nokwaneliseka kwamakhasimende. Ukuhlola amasu abo kanye nokuba khona kwemakethe kunikeza imininingwane ebalulekile ngokwethembeka kwabo.

| Uhlobo Lwesu | Incazelo |

|---|---|

| Ukuqamba Okuqhubekayo | Izinkampani zitshala imali ku-R&D ukuze kuthuthukiswe ukusebenza nokusebenza kahle kwama-extruder, ahlangabezane nezidingo ezahlukahlukene zezimboni. |

| Ubambiswano Oluhlelekile | Izivumelwano nabadlali bezimboni nezikhungo zocwaningo ukuze kuthuthukiswe ubungcweti nokwandisa izinhlelo zokusebenza. |

| Ukuhlanganiswa Nokutholwa | Ukuthuthukisa amakhono okukhiqiza kanye nokufinyelela ezimakethe ngokuhlanganisa amasu nokutholwa. |

Abakhiqizi ababeka phambili la maqhinga bavame ukuletha izixazululo ezisezingeni eliphezulu ezihambisana nezimfuno zemboni. Isibonelo, i-Zhejiang Jinteng Machinery Manufacturing Co., Ltd. iyisibonelo sale ndlela ngokuhlanganisa amakhono okuklama athuthukile nezisetshenziswa zomshini ezinembayo. Ukugxila kwabo ekusungulweni nasekulawuleni ikhwalithi kuqinisekisa ukusebenza okungaguquki kanye nokwaneliseka kwamakhasimende.

Iqhaza Lokubuyekezwa Kwekhasimende Nobufakazi

Ukubuyekezwa kwekhasimende nobufakazi kunikeza imininingwane ebalulekile ngesithunzi somkhiqizi nokuthembeka komkhiqizo. Lawa ma-akhawunti azibonela mathupha agqamisa ukuzizwisa komhlaba wangempela, esiza abangaba abathengi benze izinqumo ezinolwazi. Izibuyekezo ezinhle zivame ukugcizelela izici ezibalulekile njengokuqina komkhiqizo, ukusebenza kalula, nokusekelwa ngemva kokuthengisa.

Ithiphu: Bheka izibuyekezo ezichaza ukusebenza kwesikhathi eside nokuzizwisa ukulungiswa. Le mininingwane ivamise ukwembula inani langempela le-extruder ngale kokuthenga kwayo kokuqala.

Ubufakazi obuvela kochwepheshe bemboni nakho kungaqinisekisa izimangalo zomkhiqizi. Isibonelo, impendulo evela ezinkampanini ezisebenzisa izikulufo ezingamawele zezinto zokwakha ezine-viscosity ephezulu noma ukwakheka okuyinkimbinkimbi kungaqinisekisa amandla omshini. Iphethini engaguquki yokubuyekezwa okuhle ikhombisa ukuzibophezela komkhiqizi kukhwalithi nokwaneliseka kwamakhasimende.

Ukubaluleka Kweziqinisekiso Nokusekelwa Kwezobuchwepheshe

Iziqinisekiso nokusekelwa kwezobuchwepheshe kudlala indima ebalulekile ekuqinisekiseni ukusebenza kokukhiqiza okungaphazamiseki. Iwaranti ebanzi ibonisa ukuzethemba komkhiqizi ekuqineni nasekusebenzeni komkhiqizo wabo.Ukwesekwa okuthembekile kwezobuchwephesheinciphisa isikhathi sokuphumula futhi ibhekane nezinselele zokusebenza ngempumelelo.

Izinzuzo ezibalulekile zosekelo oluqinile ngemuva kokuthenga zifaka:

- Ukugcinwa okuthembekile kuqinisekisa ukusebenza kahle.

- Ukufinyelela kalula izingxenye ezisele kunciphisa ukubambezeleka kokukhiqiza.

- Ukwesekwa okubanzi kobuchwepheshe kusiza ukusebenza okungaphazamiseki.

Abakhiqizi abanikeza amawaranti amaningi kanye nezinsizakalo zokusekela ezisabelayo babonisa ukuzibophezela empumelelweni yamakhasimende. Isibonelo, izinkampani ezihlome ngemishini yokuqapha neyokuhlola ethuthukisiwe zinganikeza ukuxilonga okunembayo nezinqumo ezisheshayo. Leli zinga losekelo aligcini nje ngokuthuthukisa impilo ende yomshini kodwa futhi lakha ukwethembana kumakhasimende.

Qaphela: Njalo qinisekisa ukutholakala kwezingxenye ezisele kanye nokusabela kwamaqembu osekelo lobuchwepheshe ngaphambi kokuphothula ukuthenga. Lezi zici zithinta kakhulu ukusebenza kahle kwesikhathi eside.

Ukukhetha i-twin screw plastic extruder elungile kubandakanya ukuhlola ukuhambisana, ukwenza ngendlela oyifisayo, ukusebenza, izindleko, nokuthembeka. Abakhiqizi kufanele babeke phambili abahlinzeki abathembekile ngeziqinisekiso eziqinile nokusekelwa kobuchwepheshe. Ukugwema izinqumo ezisheshayo kuqinisekisa impumelelo yesikhathi eside.

Ithiphu: Dala uhlu lokuhlola izidingo futhi uqhathanise izinketho ngokuhlelekile ukuze uthenge unolwazi.

Isikhathi sokuthumela: May-22-2025