Ukukhetha ikhwalithi ephezuluizikulufo ze-nitrided nemiphongolokubalulekile ekuqinisekiseni ukusebenza kahle kwemishini. Izinto ezifana nohlobo lwezinto ezibonakalayo, ukuhambisana komklamo, nezidingo zohlelo lokusebenza zinethonya elikhulu kulokhu kukhetha. Izinqumo ezinolwazi azigcini nje ukuthuthukisa isikhathi sokusebenza sezingxenye ezifana ne-I-Extrusion Machine Single Screw Barelkanye neI-Pvc Pipe Single Screw Barrelkodwa futhi ngcono ukusebenza kahle kanye nokukhiqiza jikelele.

Ukukhetha Okubalulekile Kwezikulufu Nemiphongolo Ye-Nitrided

Ukukhetha izinto ezifaneleizikulufo ze-nitrided nemiphongolokubalulekile ukuze kuzuzwe ukusebenza kahle ezinhlelweni ezihlukahlukene. Izinto ezisetshenziswayo zithonya kakhulu ukuqina, ukusebenza kahle, kanye nempumelelo iyonke yalezi zingxenye.

Izinhlobo Zezinto

Izinto eziningi ezisetshenziswayo zivame ukusetshenziswa lapho kukhiqizwa izikulufo ze-nitrided nemiphongolo. Into ngayinye inezici ezihlukile ezithinta ukufaneleka kwayo kwezinhlelo zokusebenza ezithile. Nazi ezinye zezinto ezivame kakhulu:

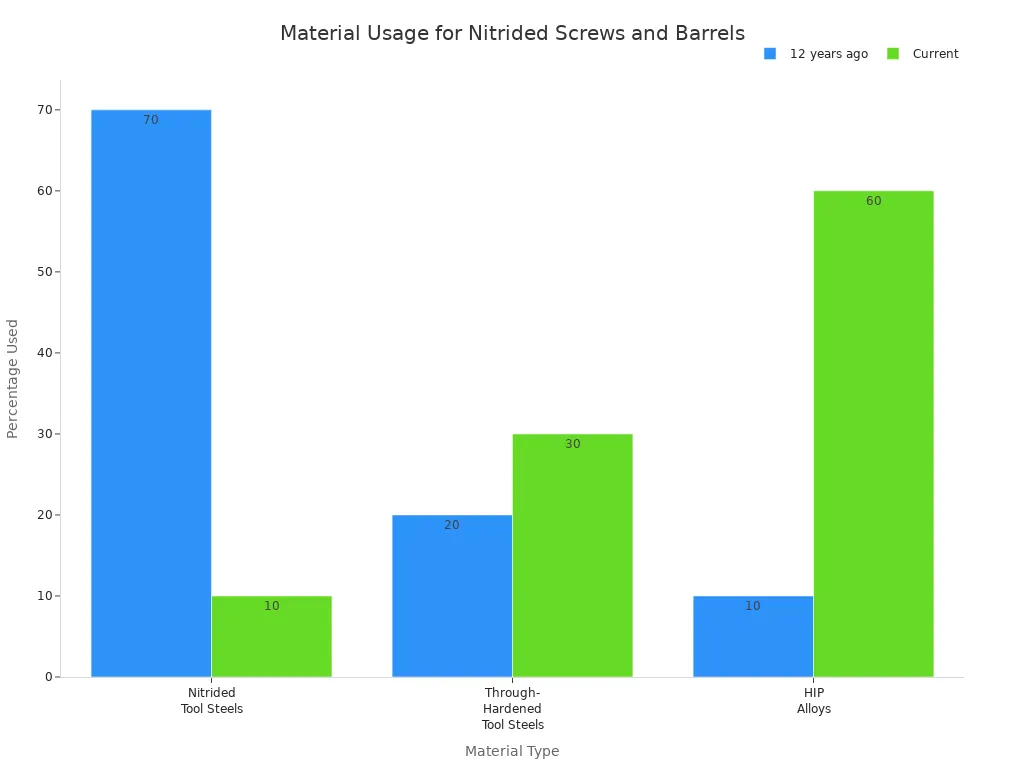

- I-Nitrided Tool Steels: Ngokomlando, lezi zinsimbi zazibalelwa ku-70% wesabelo semakethe eminyakeni eyishumi nambili edlule. Kodwa-ke, ukusetshenziswa kwabo kwehle kwafinyelela cishe ku-10% okwamanje.

- Nge-Hardened Tool Steels: Lolu hlobo lubone ukwanda kokuthandwa, lukhuphuka lusuka ku-20% lwaya ku-30% ngesikhathi esifanayo.

- I-HIP Alloys: Lawa ma-alloys athole ukudonsa okubalulekile, asuka ku-10% kuya ku-60% ekusetshenzisweni kwamanje.

Ithebula elilandelayo lifingqa izinguquko ekusetshenzisweni kwezinto phakathi neminyaka:

| Uhlobo Lwezinto | Iphesenti (iminyaka engu-12 edlule) | Iphesenti (Okwamanje) |

|---|---|---|

| I-Nitrided Tool Steels | 70% | 10% |

| Nge-Hardened Tool Steels | 20% | 30% |

| I-HIP Alloys | 10% | 60% |

Izakhiwo ze-Nitrided Materials

Izinto ezisetshenziswayo ezine-nitrided zibonisa izici eziningi ezinenzuzo ezithuthukisa ukusebenza kwazo ezinhlelweni zezimboni. Inqubo ye-nitriding yethula i-nitrogen ebusweni bezinto ezibonakalayo, yenze ungqimba lwe-nitride oluqinile. Lesi singqimba sithuthukisa kakhulu izici ezihlukahlukene zemishini, okwenza izinto ze-nitrided zifiseleke kakhulu.

- Gqoka Ukumelana: Izinto ze-nitrided zibonisa ukumelana okuhle kakhulu kokugqoka ngenxa yongqimba oluqinile olwakhiwe ngesikhathi se-nitriding. Lesi sakhiwo sibalulekile ezingxenyeni ezingaphansi kwezimo zokuhuzuka, njengezinqubo ze-extrusion.

- Ukumelana Nokugqwala: Isendlalelo se-nitride sinikeza ukumelana okuthuthukisiwe ekugqwaleni, okubalulekile lapho usebenza nama-polymer ancibilikisiwe nezinye izakhi ezigqwalayo.

- Ukuqina: Ngemuva kwe-nitriding, izinto ezisetshenziswayo zingafinyelela amazinga okuqina angaphezu kwama-65 HRC. Lokhu kwanda kokuqina kunomthelela emandleni jikelele kanye nokuqina kwezikulufu nemiphongolo.

- Izakhiwo Eziphelele: Insimbi ene-nitrided nama-alloys athile afana ne-38CrMoAl ayaziwa ngezakhiwo zawo ezinhle kakhulu zizonke, okuwenza afanelekele izinhlelo zokusebenza ezihlukahlukene.

Ithebula elilandelayo libonisa izici eziyinhloko zemishini yezinto ze-nitrided ezisetshenziswa kuzikulufu nemiphongolo:

| Impahla | Incazelo |

|---|---|

| Gqoka Ukumelana | Izinto ze-nitrided zibonisa ukumelana okuhle kakhulu kokugqoka ngenxa yenqubo ye-nitriding. |

| Ukumelana Nokugqwala | Banokumelana nokugqwala okuhle, nakuba amanye amabanga angase abe nemikhawulo. |

| Ukuqina | Ukuqina kwe-post-nitriding bungadlula ama-65 HRC, okuthuthukisa amandla ewonke. |

| Izakhiwo Eziphelele | Insimbi ye-Nitrided kanye ne-38CrMoAl yaziwa ngezakhiwo zayo ezinhle kakhulu. |

| I-Nitriding Layer Depth | Ngokuvamile, ungqimba lwe-nitriding lufinyelela ku-0.4-0.6 mm. |

Izinto Okufanele Zicatshangelwe Ekukhetheni Izingxenye Ze-Nitrided

Niniukukhetha izikulufu ze-nitrided nemiphongolo, kunezici ezimbili ezibalulekile eziba khona: ukuhambisana komklamo kanye nezidingo zohlelo lokusebenza. Ukuqonda lezi zici kuqinisekisa ukuthi izingxenye ezikhethiwe zisebenza kahle kakhulu endaweni ezihlosiwe.

Ukuhambisana Kwedizayini

Ukuhambisana kwedizayini kubalulekile ekuhlanganisweni ngempumelelo kwezikulufu ze-nitrided nemiphongolo emishinini ekhona. Izici eziningi zedizayini kufanele zicatshangelwe ukuze kuqinisekiswe lokhu kuhambisana:

| Isici Sokuklama | Incazelo |

|---|---|

| Ukukhetha Okubalulekile | Insimbi ene-nitrided ikhethwa ngenxa yendawo yayo eqinile kanye nokumelana nokugqwala. |

| Ukufakwa Kwemigqomo | Imiphongolo ye-Bimetallic enezingubo zokugqoka ezigqokekayo iyadingeka ekusebenzeni okuphezulu. |

| I-Screw Geometry | I-screw geometries eklanywe ngokukhethekile ithuthukisa ukukhonjwa nokuphumayo. |

| Isilinganiso se-L/D | Isilinganiso sobude bezikulufu kuya kububanzi buthinta izinqubo zokuncibilika nokuxuba. |

| Isilinganiso sokucindezela | Izilinganiso zokucindezela eziphakeme zithuthukisa ukusebenza kokuxubana nokukhishwa kwengcindezi. |

| Isilinganiso Sokujula Kwendiza | Ilawula umthamo wokuthuthwa kwempahla nokusebenza kokugeleza komgqomo. |

Insimbi ye-nitrided inikeza ukuqina nokumelana nokugqoka, okwenza kube ukukhetha okudumile. Imiphongolo ye-Bimetallic ithuthukisa ukusebenza ezindaweni ezilumayo, kuyilapho izikulufu ezinde zithuthukisa ukusebenza kahle kokucubungula izinto. Ukwenyuka kwezilinganiso zokuminyanisa kuholela ekuxubeni okungcono nasekukhipheni ingcindezi, okubalulekile ukuze kuzuzwe amazinga aphezulu okukhiqiza.

I-HMG Extrusions igcizelela ukubaluleka kokusebenzisa insimbi ye-nitriding engagugi kakhulu yezikulufo. Lokhu kunaka imininingwane kusiza ukugcina ukucaciswa okuqinile kokubekezelelana, okuqinisekisa ukuhambisana nemishini ekhona.

Izidingo Zohlelo

Izidingo zohlelo lokusebenza zidlala indima ebalulekile ekunqumeni ukufaneleka kwezikulufu ze-nitrided nemiphongolo. Okucatshangelwayo okubalulekile kuhlanganisa:

- Ukucatshangelwa kokuklama: Idizayini kufanele ibhekane nezici ezibonakalayo ezifana ne-viscosity, indawo encibilikayo, nezinga lokugeleza.

- Ukuncibilika Okufanayo Nokuxuba: Idizayini efanele iqinisekisa ukuthi izinto zepulasitiki ziyancibilika ngokufanayo futhi zihlanganiswe, zivimbela ukushisa nokushisa.

- Ubushelelezi bobuso: Ukuthuthukisa ukushelela kwendawo kubalulekile ekuhlanganiseni izinto ezibonakalayo, ukugunda, nokudlulisa. Lokhu kuba nomthelela ngqo ekusebenzeni kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

Ukubekezelelana kwe-Dimensional nakho kuthinta ukusebenza. Ukugqoka izikulufu nemiphongolo kungathinta kakhulu ukusebenza kahle kwe-plasticizing, ingcindezi yangemuva, ivolumu yokudubula, izikhathi zomjikelezo, nokungaguquguquki kwengxenye. Izingxenye ezigugile zinganciphisa ukusebenza kahle kokucubungula kufika ku-25%, zikhuphule ukusetshenziswa kwamandla, futhi ziholele ekulimaleni ezingxenyeni ezibunjiwe. Ukweqa imvume phakathi kwesikulufu nomgqomo kungaholela ekuvuzeni kwe-resin, izinga eliphansi lokuncibilika, kanye nengcindezi yomjovo engahambisani.

Amathiphu Okunakekela Ukuphila Isikhathi Eside

Ukugcinwa kahle kwezikulufu ze-nitrided nemiphongolo kubalulekile ukuze kwandiswe impilo yazo kanye nokuqinisekisa ukusebenza kahle. Ukusebenzisa uhlelo oluqinile lokuvikela (PM) kunganciphisa kakhulu ukuguga futhi kunwebe impilo yalezi zingxenye.

Ukuhlanza Nokunakekela

Ukuhlanza njalo nokugcobisa kubalulekile ekuvimbeleni ukuguga ngaphambi kwesikhathi. Nansi imikhuba enconyiwe:

- Sebenzisa ama-Compounds Purging Compounds (CPCs): Lezi zinhlanganisela zithuthukisa ukusebenza kahle kokuhlanza futhi zisiza ukususa izinsalela ku-screw kanye nomgqomo.

- Landela Izincomo Zomkhiqizi: Namathela kuzinkombandlela ezinikezwe abakhiqizi bezikulufa nemigqomo ukuze ulungiswe njalo.

Ukuze ulondoloze izingxenye ngempumelelo, cabangela imvamisa yokulungisa elandelayo:

| Imvamisa Yokulungisa | Incazelo Yomsebenzi |

|---|---|

| Maviki onke | Shintsha isihlungi sikawoyela othambisayo sesinciphisi futhi uhlole ukungcola. |

| Nyanga zonke | Hlola ukuhlangana kwe-motor coupling futhi uyilinganise. |

| Ngekota | Ukuhlola okuphelele kokuhlakazwa kwesikulufu, umgqomo, kanye nesikhunta. |

Ukuhlola Nokushintsha

Ukuhlola okuvamile kubalulekile ukuze kutholwe ukuguga noma ukulimala kwezikulufu ezine-nitrided nemiphongolo. Ochwepheshe kufanele bafake amasu alandelayo ezinhlelweni zabo zokulungisa:

- Yenza ukuhlolwa okujwayelekile kwezingxenye ze-plasticizing.

- Linganisa ukugqokwa ngesikhathi sokuhlolwa okuhleliwe ukuze udale iphrofayela yokugqokwa.

- Khomba isikhathi sokuphila esilindelekile sezingxenye zokushintshwa nokulungisa okuhleliwe.

Ukuhlola njalo izikulufu nemiphongolo kuvumela ukutholwa kusenesikhathi kwezinkinga ezingaba khona, okuvumela ukungenelela okusheshayo. Ithebula elilandelayo libonisa ubude besikhathi obujwayelekile bezingxenye ezihlukahlukene:

| Uhlobo Lwengxenye | Ubude bempilo (Iminyaka) | Amanothi |

|---|---|---|

| Izikulufo ezijwayelekile | 1 – 1.5 | Okwamapulasitiki enhloso ejwayelekile (isb, i-PP/PE) |

| Izikulufo ezijwayelekile | 0.5 - 0.67 | Okokugcwalisa (isb, i-fiberglass) |

| Ukuphila komgqomo | 1.5 - 2 izikhathi | Ngokuvamile isikhathi eside kunesikulufu sokuphila; shintsha uma ungaphezu kweminyaka emi-3. |

| Ukushintsha Isu | N/A | Shintsha isikulufu nomgqomo njengesethi yezinzuzo zezomnotho. |

Ngokulandela leziamathiphu esondlo, ama-opharetha angaqinisekisa ukuphila isikhathi eside nokuthembeka kwezikulufu nemiphongolo ye-nitrided yekhwalithi ephezulu.

Ukucatshangelwa Kwezindleko Zekhwalithi Ephakeme I-Nitrided Screw kanye Nomphongolo

Lapho utshala imali ngezikulufo ze-nitrided nemiphongolo yekhwalithi ephezulu, ukuqondaizindlekokubalulekile. Izinkampani kufanele zilinganisele izindleko zokuqala nezinzuzo zesikhathi eside ukuze zenze izinqumo ezinolwazi.

Ukubhajethela Ikhwalithi

Ukwenza isabelomali sezingxenye ze-nitrided kudinga ukucatshangelwa ngokucophelela kwezici ezihlukahlukene. Izinkampani kufanele zihlole izici ezilandelayo:

- Uhlobo lwepulasitiki olucutshungulwayo: Nquma ukuthi isicelo sibandakanya amapulasitiki ajwayelekile noma aqinisiwe. Lokhu kukhetha kunomthelela ekukhethweni kwezinto ezibonakalayo nezindleko ezihambisanayo.

- Izithasiselo ezisetshenzisiwe: Hlola ukuthi izithasiselo zinethonya kanjani ukuguga nokuphila isikhathi eside. Lezi zici zingathinta kakhulu izindleko zizonke.

- Isikali sokukhiqiza: Ukusebenza kwevolumu ephezulu kufanele kubeke phambili ama-alloys aqinile. Ukutshala imali ezintweni ezihlala isikhathi eside kunomvuzo ngokuhamba kwesikhathi.

- Ukucatshangelwa kwesabelomali: Ukukhetha izinketho ze-bimetallic noma eziboshwe kungaholela ekongeni isikhathi eside. Lezi zinketho zivame ukunciphisa izindleko zokunakekela kanye nokushintshanisa.

Izindleko eziphakeme zokuqala zezingxenye ze-bimetallic, njengezikulufi ezine-nitrided nemiphongolo, zivela ezinqubweni zokukhiqiza eziyinkimbinkimbi nezinto ezikhethekile. Lobu bunzima buholela ekwenyukeni kwezindleko zokukhiqiza, okuba nomthelela omkhulu entengo yokugcina yalezi zingxenye. Emikhakheni efana neyezimoto, isidingo semiphongolo yesikulufu se-nitriding steel sisukela ebukhuni bawo obuphakeme kanye nokumelana nokugqokwa. Lezi zakhiwo zithethelela izinto eziphakeme kanye nezindleko zokukhiqiza.

Ivelu Yesikhathi eside vs. Izindleko Zokuqala

Ukutshala imali kuzingxenye ze-nitrided zekhwalithi ephezulu kungaveza ukonga okukhulu kwesikhathi eside. Lezi zingxenye ngokuvamile zihlala izikhathi ezi-2 kuya kwezi-5 kunezinye izindlela ezingenayo i-nitrided. Lokhu kuphila isikhathi eside kunciphisa imvamisa yokushintshwa nokunakekelwa, okuholela ezindleko eziphansi eziphelele zobunikazi bemishini namasistimu asebenzisa izingxenye ze-nitrided.

Ithebula elilandelayo libonisa ukuthi izici ezihlukahlukene zinethonya kanjani izindleko zobunikazi:

| Isici | Umthelela Ezindlekweni Zobunikazi |

|---|---|

| Gqoka Ukumelana | Ukushintshwa okumbalwa, izindleko eziphansi |

| Imvamisa Yokulungisa | Isikhathi esincane sokuphumula, ukunciphisa izindleko zabasebenzi |

| Ukusebenza Kwamandla | Izindleko eziphansi zezinsiza |

| Ukuqapha Okubikezelwayo | Ukutholwa kusenesikhathi, ukulungisa okuncishisiwe |

Ngokucabangela kokubili izindleko zokuqala kanye nenani lesikhathi eside, izinkampani zingenza izinqumo zamasu ezithuthukisa ukusebenza kahle nokusebenza futhi zinciphise izindleko zizonke. Ukutshala imali kuzikulufu nemiphongolo ye-nitrided yekhwalithi ephezulu akuthuthukisi ukusebenza kuphela kodwa futhi kunomthelela ekubukekeni kwezimali okuzinzile.

Ukukhetha izikulufu ze-nitrided ezifanele kanye nemiphongolo kuhilela ukucatshangelwa ngokucophelelaukuhambisana kwezinto ezibonakalayokanye nezinqubo zokunakekela. Izici ezibalulekile zifaka phakathi ukukhetha izinto ezingagugi njengensimbi ye-nitrided kanye nokwenza ukuhlolwa okuvamile. Ngokwenza izinqumo ezinolwazi, opharetha bangathuthukisa ukusebenza futhi bandise isikhathi sokuphila sezingxenye zabo zemishini.

Okubalulekile Okuthathwayo:

- Ukuhambisana kwezinto kuthinta ukuguga nokumelana nokugqwala.

- Ukunakekelwa okuvamile kunciphisa isikhathi sokuphumula futhi kuthuthukisa ukusebenza kahle.

FAQ

Iyini inqubo ye-nitriding?

I-Nitriding iwukwelapha okuqinisa indawo okusabalalisa i-nitrogen ku-material, okwenza ungqimba lwe-nitride oluqinile.

Ngabe i-nitriding ithuthukisa kanjani ukusebenza kwesikulufa nomgqomo?

I-Nitriding ithuthukisa ukumelana nokugqokwa, ukumelana nokugqwala, futhi inciphisa ukungqubuzana, okuholela empilweni ende yesevisi kanye nokusebenza kahle okuthuthukisiwe.

Yiziphi izinqubo zokunakekela ezinweba ukuphila kwezingxenye ze-nitrided?

Ukuhlanza njalo, ukugcotshwa, nokuhlola kusiza ukuthola ukuguga kusenesikhathi, ukuqinisekisa ukusebenza kahle nokuphila isikhathi eside kwezikulufu ezine-nitrided nemiphongolo.

Isikhathi sokuthumela: Sep-16-2025