Ngiyabona ukuthi kanjaniAma-Single Screw Barrelsguqula ukugaywa kabusha kwepulasitiki. Uma ngisebenzisa i-Single screw barrel ukuze ngigaye kabusha imbudumbudu, ngibona ikhwalithi engcono yokuncibilika, ukuxubana okuqinile, nokuguga okuncane. EyamiI-Plastic Extruder Yokugaywa kabusha kwePlastikiihamba kahle. Ngezinga lokushisa elinembile nesivinini sesikulufa, yamiI-Extruder Ye-Plastic Recyclingifinyelela okukhiphayo okuphezulu kanye nekhwalithi ye-pellet.

- Ukuncibilika kwe-flux

- Isivinini sesikulufa

- Izinga lokushisa lomgqomo

- Shear ukucindezeleka ukuphathwa

Izindlela Ezibalulekile Zokushayela Ngempumelelo

I-Melt Homogenization Ethuthukisiwe

Uma ngisebenzisa i-extruder yami yokugaya kabusha, ngigxila ekutholeni ukuncibilika okufanayo. I-Melt homogenization isho ukuxuba ipulasitiki kahle njengoba incibilika, ngakho i-pellet ngayinye inekhwalithi efanayo. Ngikufundile lokhoukulawula izinga lokushisa lokuncibilika nokugelezakubalulekile. Ucwaningo lwamapulasitiki afana nenayiloni ne-polypropylene lubonisa ukuthi uma ngigcina iyunifomu encibilikayo, ngithola ama-pellets agaywe kabusha angcono. Uma ukuncibilika kungahambisani, ipulasitiki egaywe kabusha ingaba buthakathaka noma ibe brittle.

Ngibona umehluko kukhwalithi ye-pellet uma ngisebenzisa i-screw barrel eyodwa edizayinelwe ukuxuba okungcono. Isibonelo, ucwaningo lwe-melt-state shear homogenization lubonisa ukuthi ukuxutshwa kwe-shear ephezulu emiphongolweni yesikulufu esisodwa kuthuthukisa ukufana okungokomzimba nokushisayo kwamapulasitiki agaywe kabusha. Le nqubo inciphisa ukungcola futhi iguqule isakhiwo se-polymer ngendlela esiza ngezinye izinyathelo zokuvuselela kabusha. Ngiyaqaphela ukuthi ama-pellets ami asetshenziswe kabusha anokukhubazeka okumbalwa nokusebenza okungcono uma ukuncibilika kufana.

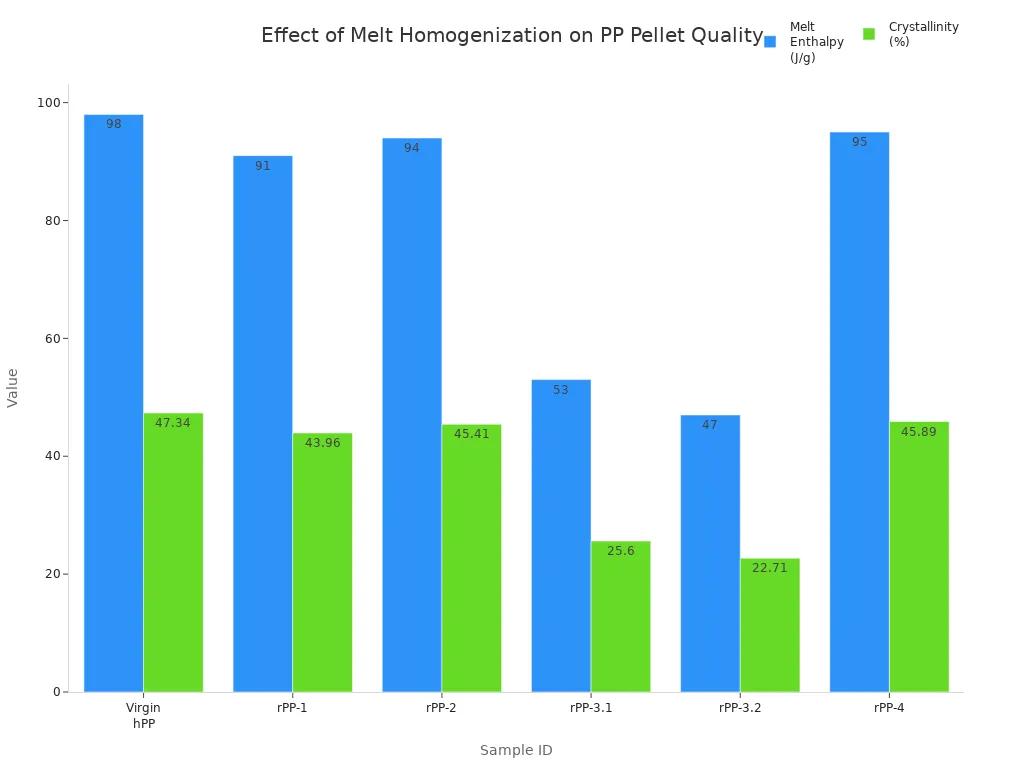

Izinombolo zisekela lokho engikubona esitolo sami. Uma ngiqhathanisa amasampula e-polypropylene agaywe kabusha, lawo anobucwebe obuphakeme kanye ne-ncibilikisa i-enthalpy abukeka futhi enze kakhulu njengepulasitiki emsulwa. Nali ithebula elibonisa ukuthi izimo ezihlukene zokucubungula ziyithinta kanjani ikhwalithi ye-pellet:

| I-ID yesampula | I-Melt Enthalpy (J/g) | I-Crystallinity (%) |

|---|---|---|

| I-Virgin homopolymer PP (hPP) | 98 | 47.34 |

| I-PP-1 egaywe kabusha (rPP-1) | 91 | 43.96 |

| I-PP-2 egaywe kabusha (rPP-2) | 94 | 45.41 |

| I-PP-3.1 egaywe kabusha (rPP-3.1) | 53 | 25.60 |

| I-PP-3.2 egaywe kabusha (rPP-3.2) | 47 | 22.71 |

| I-PP-4 egaywe kabusha (rPP-4) | 95 | 45.89 |

Ngihlale ngihlose imiphumela efana ne-rPP-1, i-rPP-2, ne-rPP-4, eseduze ne-virgin PP. Amanani aphansi, afana ne-rPP-3.1 kanye ne-rPP-3.2, angitshela ukuthi ukuncibilika akuzange kuxutshwe kahle noma kube nokungcoliswa.

Uma ngilawula ukugeleza nokuxutshwa kwe-melting, futhi ngibona izakhiwo ezingcono zemishini kumkhiqizo wokugcina. Ama-pellets ami agaywe kabusha anwebeka futhi aphakamise cishe kanye nopulasitiki omusha, okusho ukuthi ngingawasebenzisa ezinhlelweni ezidingeka kakhulu.

I-Optimized Screw Geometry

Ukuma nokwakheka kwesikulufu ngaphakathi kwe-extruder yami kwenza umehluko omkhulu. Ngizamile ama-screw geometries futhi ngaqaphela ukuthi athinta kanjani ukusetshenziswa kwamandla, ikhwalithi yokuncibilika, kanye nokuphumayo. Uma ngisebenzisa isikulufu esinejiyomethri efanele, ngithola ukuxubana okungaguquki kanye nokuphuma okuphezulu. Ngiphinde ngisebenzise amandla amancane, okonga imali futhi anciphise ukuguga emishinini yami.

- I-Screw geometry ithinta ukuthi angakanani amandla engiwadingayo nokuthi izinga lokushisa elincibilikayo lihlala lizinzile.

- Ukwenyusa isivinini sesikulufa kungehlisa ukusetshenziswa kwamandla, kodwa idizayini yesikulufu kufanele ifane nokokusebenza.

- Izikulufu zokuvimbela kanye nezici zokuxuba zisiza ukugcina izinga lokushisa elincibilikayo lilingana futhi lithuthukise ukuxutshwa.

- Eminye imiklamo yezikulufo ingivumela ngiqhube i-extruder ngokushesha ngaphandle kokulahlekelwa ikhwalithi.

- Ijiyomethri eyisikulufu elungile ibhalansisa ukusebenza kahle kwamandla ngokukhipha okuphezulu kanye nekhwalithi enhle yokuncibilika.

Ngibonile ukuthi izikulufu zokuvimbela, ezihlukanisa ipulasitiki eqinile futhi encibilikisiwe, zingivumela ukuthi ngigijime ngesivinini esiphezulu futhi ngithole okuphumayo okwengeziwe. Kodwa-ke, ngidinga ukubuka ukuphuma ukuze ngigcine iyunifomu encibilikayo. Ukuxuba izakhi ezifana nesigaba se-Maddock shear kunginika i-homogenization engcono, okusho ukuthi amaphutha ambalwa kuma-pellets ami.

Nasi ukuqhathanisa okusheshayo kwezinhlobo zezikulufa nemiphumela yazo:

| I-Screw Geometry | Ukuxuba Ukuvumelana (Homogeneity) | Okokusebenza | Amanothi |

|---|---|---|---|

| Izikulufo Zesithiyo | Kuhle ekusebenzeni okuphezulu, kudinga ukulawula ngokucophelela | Phezulu | Kuhle kakhulu kumaqoqo amakhulu, bukela ukuxubana okungalingani ngesivinini esikhulu kakhulu |

| Izikulufu ezinezigaba ezintathu | Izinzile, kodwa eziphansi | Kuphakathi | Ilungele ukukhiqizwa okuzinzile, ayiguquguquki kancane |

| Ukuxuba Izinto | I-homogenization enhle kakhulu | Iyahlukahluka | I-Maddock shear inikeza ukuxuba okungcono kakhulu, ikakhulukazi kumapulasitiki aqinile |

Ngihlala ngikhetha i-screw geometry efana nepulasitiki engiyigaya kabusha. Ngale ndlela, ngithola ibhalansi engcono kakhulu yejubane, ikhwalithi, nokusetshenziswa kwamandla.

Izinto Ezithuthukisiwe Zemigqomo

Izinto zomphongolo wesikulufa zibaluleke kakhulu njengokuklama kwayo. Ngithembele emiphongolweni eyenziwe ngezinsimbi ze-alloy zekhwalithi ephezulu njenge-38CrMoAl, enikeza amandla nokuqina. Uma ngisebenzisa imiphongolo enezindawo ezine-nitrided, ngibona ukweqa okukhulu kobulukhuni. Lokhu kusho ukuthi okokusebenza kwami kuhlala isikhathi eside, ngisho noma ngicubungula amapulasitiki abrasive noma angcolile.

- Izinsimbi ze-alloy ezifana ne-38CrMoAlA ne-AISI 4140 zinginika ukuqina engikudingayo.

- Izinsimbi ze-powder metallurgy zinikeza ukuguga okungcono kakhulu nokumelana nokugqwala.

- Ukwelashwa kwe-nitriding kukhulisa ubulukhuni bobuso, ngokuvamile bufinyelela ku-HV900 noma ngaphezulu.

- Izembatho ze-Bimetallic, njenge-tungsten carbide, zivikela kuma-filler abrasive.

- I-Chromium plating ingeza esinye isendlalelo sokuzivikela ngokumelene nokugqwala nokuguga.

Ngiye ngaphawula ukuthi lapho ngisebenzisa imiphongolo enalezi zinto eziphambili kanye nama-coatings, ngichitha isikhathi nemali encane ngilungisa. I-extruder yami isebenza isikhathi eside phakathi kwezikhawu zesevisi, futhi akudingeki ngikhathazeke kakhulu ngokuphuka. Lokhu kwethenjwa kungivumela ukuthi ngigxile ekukhiqizeni amapellets agaywe kabusha ekhwalithi ephezulu.

Ithiphu:Njalo fanisa neimpahla yomgqomoezinhlotsheni zamapulasitiki nezithasiselo ozicubungulayo. Izinto eziqinile kanye nama-coatings akhokha uma uphatha imfucumfucu yepulasitiki exubekile.

Ngokuhlanganisa i-melt homogenization ethuthukisiwe, i-screw geometry ethuthukisiwe, nezinto ezithuthukisiwe zemiphongolo, ngifinyelela ukusebenza kahle okuphezulu kanye nemiphumela engcono ekusebenzeni kwami kabusha kwepulasitiki. Lezi zindlela zisebenza ndawonye ukuze zilethe ikhwalithi engaguquki, okukhiphayo okuphezulu, kanye nezindleko eziphansi.

Ukuxazulula Izinselele Ezivamile Zokugaywa kabusha

Ukubhekana nokungcoliswa kanye ne-variable feedstock

Uma ngiqhuba umsebenzi wami wokugaya kabusha, ngibhekana ne-feedstock engalindelekile nsuku zonke. Amanye amaqoqo aqukethe amapulasitiki ahlanzekile, afanayo. Ezinye zifika zixutshwe nokungcola, insimbi noma umswakama. Ngiyazi ukuthi izinhlayiya ze-regrind ezimise ngendlela engavamile zinokuminyana kwenqwaba kunama-virgin pellets. Lokhu kunciphisa ukuphuma futhi kwenza i-extruder yami isebenze kanzima. Uma ngingazixazululi lezi zinkinga, ngibona izinga lokushisa eliphezulu lokuncibilika kanye nekhwalithi ye-pellet eyonakele.

Ngithembele emgqonyeni wami wesikulufa owodwa ukuze ngibhekane nalezi zinselelo. Ijiyomethri yendawo yokuphakelayo ethuthukisiwe, ikakhulukazi amaphakethe okuphakelayo akhulisiwe, ithuthukisa ukuphakela kanye nokuhanjiswa okuqinile. Lo mklamo uvimbela ukumiswa kwezinto futhi ugcina ukugeleza kuzinzile. Ngiyaqaphela ukuthi i-extruder yami igcina ikhwalithi yokuncibilika ngisho nalapho ngicubungula amapulasitiki axubile noma angcolile.

Nazi izinselelo ezinkulu engihlangabezana nazo ekugayweni kabusha kwepulasitiki:

- Umumo we-regrind ongajwayelekile kanye nokuminyana kwenqwaba ephansi

- Ukwehliswa kokuphuma nokusebenza kahle

- Amazinga okushisa aphakeme ancibilikayo namafasitela okucubungula amancane

- Ukungcoliswa kanye nokucekelwa phansi kwempahla

- Ukucubungula ukuhlukahluka ngamapulasitiki axubile

I-single screw barrel ingisiza ukuthi nginqobe lezi zinkinga. Ngibona ukusebenza kahle kokuphakelayo, ukugeleza kwezinto ezingaguquki, nokusetshenziswa kwamandla okuphansi. Lobu buchwepheshe bungivumela ukuthi ngicubungule uhla olubanzi lwamapulasitiki agaywe kabusha ngaphandle kokudela ikhwalithi.

Ngivame ukuqhathanisa ama-screw extruder ama-twin screw extruder. Imishini yezikulufu ezimbili ihlinzeka ngokuxuba okuhle kakhulu nokususa umoya, kodwa ilwa nokucindezela okukhulu nokungcola. Ama-extruder ngesikulufu esisodwa, njengesami, aphatha ukugaywa kabusha okugxilisa kakhulu ukuhlunga futhi abekezelele ukungcola kangcono. Nasi isiqhathaniso esisheshayo:

| Isici | I-Single Screw Extruder | I-Twin Screw Extruder |

|---|---|---|

| Ukuxuba Ukusebenza kahle | Ukuxuba okumaphakathi, i-homogenization elinganiselwe | Ukuxuba okuhle kakhulu, isenzo esinamandla sokusabalalisa/sokusabalalisa |

| I-Temperature Uniformity | Imaphakathi, ijwayele izindawo ezishisayo/ezibandayo | Ukusabalalisa izinga lokushisa lokuncibilika okufana kakhulu |

| Ukuzinza Komphumela | Kuhle, kungaba ne-pulsation | Okuphumayo okungaguquki, okuzinzile |

| I-Material Versatility | Okuhle kakhulu kwe-homogeneous, virgin materials | Iphatha izithasiselo, izingxube, izifunzo ezingcolile |

| I-Degassing Amandla | Kunomkhawulo noma akukho | Iphezulu, enezimbobo ze-vacuum nezindawo zokungenisa umoya |

| I-Ideal Use Case | Isikali esincane, i-ABS eyintombi emsulwa | Isikali sezimboni, okukhethekile, okunemibala, okugaywe kabusha kwe-ABS |

Ngikhetha imiphongolo yesikulufu esisodwa ngamakhono awo wokucindezela okuphezulu nokubekezelela kangcono ukungcola. Lesi sinqumo singisiza ngigweme ukulungiswa okumba eqolo futhi sigcine ulayini wami wokugaya kabusha usebenza kahle.

Ukunciphisa Ukugqokwa Ezintweni Eziqhumayo

Amapulasitiki abrasive nama-filler, njengemicu yengilazi, i-talc, ne-calcium carbonate, aletha inselele enkulu esitshalweni sami. Lezi zinto ziguga izikulufu nemiphongolo ngokushesha. Ngangivame ukushintsha izingxenye ngokuvamile, okwandisa isikhathi sokuphumula nezindleko.

Manje, ngisebenzisa imiphongolo yesikulufu esisodwa enokwelashwa okuseqophelweni eliphezulu kanye nama-coatings. Umgqomo wami ufaka i-nitrided surface kanye nezendlalelo ze-bimetallic alloy. Lezi zithuthukisi ziqinisa ubulukhuni futhi zimelane nokuhuzuka. Ngibona umehluko omkhulu ekuqineni. Imishini yami ihlala isikhathi eside, ngisho noma ngicubungula amapulasitiki aqinile, abrasive.

Izici eziyinhloko zedizayini ezingisiza ukuba nginciphise ukuguga zihlanganisa:

- I-screw geometry elungiselelwe ukuvikela ukukhuphuka komfutho kanye nokuncibilika kwe-ncibilika

- Ukukhethwa kwezinto ezingagugi kanye nama-coatings akhethekile

- Idizayini ehlanganisiwe yezinto ezibonakalayo zokusetshenziswa nezigcwalisi

- Ukwenza imishini enembile ukuze kuqedwe phezulu okubushelelezi

- Isofthiwe yokulingisa ukuqonda ukusatshalaliswa kwengcindezi encibilikayo

Ngafunda ukuthiukugqokwa okuphezulu kwenzeka eduze kwesigaba soshintsho, lapho okuqinile kuncibilika khona nokucindezela kuphakama. Ngokukhetha izinto ezifanele kanye nama-coatings, Inciphisa ukuguga kuze kufike ku-60%. Ukuhlolwa okuvamile nokunakekelwa kwezindawo ezigqoke kakhulu, njengendawo yokudla neyokukhulula, kugcina i-extruder yami isesimweni esiphezulu.

Ithiphu:Ngihlala ngifanisa idizayini yami yomgqomo wesikulufa kumapulasitiki kanye namafayili engiwacubungulayo. Le ndlela yelula impilo yemishini futhi ithuthukisa ukusebenza kahle kokukhiqiza.

Ukuthuthukisa Ukuzinza Kwenqubo Nokungaguquguquki Kokukhiphayo

Ukucutshungulwa okuzinzile kubalulekile ekukhiqizeni amapellets agaywe kabusha ekhwalithi ephezulu. Ngaphambi kokuthi ngisebenzise ubuchwepheshe be-screw barrel eyodwa, ngizabalaza nokugeleza okugelezayo, ukungaqini kahle kokuncibilika, kanye nokudluliswa kwezinto eziqinile. Lezi zinkinga ziholele ekwehleni kwamazinga okukhiqiza, ukwanda kwezinsalela, kanye nezindleko eziphezulu zabasebenzi.

Ngomphongolo wami we-screw we-JT owodwa, ngifinyelela ukugeleza okuncibilikile okuzinzile kanye nokukhishwa okungaguquki. Amasistimu okulawula athuthukile, afaka izinzwa nezilawuli ezinengqondo, zingisiza ngigcine izinga lokushisa elizinzile nokucindezela. Ngiqapha izimo zenqubo eduze ukuze nginqande ukuguquguquka okungase kuthuntubeze ukusebenza.

Ngiyasebenzisaama-alloys e-bimetallic kanye nezingubo ezithuthukisiweukuthuthukisa ukumelana nokugqwala. Lezi zici zibalulekile ekucubunguleni amapulasitiki abrasive noma agaywe kabusha. Izimo zezinqubo ezizinzile zivimbela ukuhlukahluka kwezakhiwo zomkhiqizo futhi zinciphisa imfucuza.

Nazi izinyathelo engizithathayo ukuze ngigcine ukuzinza kwenqubo:

- Ukugcinwa okuvamile nokushintshwa ngesikhathi kwezikulufu ezigugile nemiphongolo

- Ukuqapha izinga lokushisa nokucindezela ngamasistimu okulawula athuthukile

- Ukusebenzisa amaphrofayli ayisikulufu angokwezifiso ukuze kuncibilike kangcono i-homogeneity nokuxuba

- Ukuhlola izindawo ezigqoka kakhulu ukuze kuncishiswe isikhathi sokuphumula esingalindelekile

Ucwaningo lubonisa ukuthi ukuthuthukisa isivinini sesikulufa kanye nezizoni zezinga lokushisa kwandisa ukufakwa futhi kuthuthukisa ukugaywa kabusha. Isivinini esiphansi sesikulufu sinyusa i-torque futhi sinciphisa amandla okusebenza, okuholela ekusebenzeni kahle okungcono nokukhipha okungaguquki. Ngibhale phansi izinga lokukhiphayo ngo-18% kuya ku-36% ngemva kokuthuthukisa umklamo wami wombhobho oyisikulufa.

Qaphela:Ukuhlola okungaguquguquki nokunakekela okubikezelwayo kwelula impilo yesisetshenziswa futhi kuthuthukise ukusimama kwenqubo iyonke emsebenzini wami wokugaya kabusha.

Ngokubhekana nokungcoliswa, ukuguga, kanye nokuzinza kwenqubo, umphongolo wami owodwa wesikulufa uyangisiza ukuthi ngilethe amapellets athembekile, ekhwalithi ephezulu agaywe kabusha. Ngihlangabezana nezidingo zokugaywa kabusha kwesimanje ngokuzethemba nokusebenza kahle.

I-Single Screw Barrel ye-Recycling Granulation: Imiphumela Yomhlaba Wangempela

Ukukhula Kwempumelelo Nekhwalithi

Lapho ngishintshela emgqonyeni wesikulufa owodwa wokugaywa kabusha kwembudumbudu, ngabona ukuthuthuka okucacile kukho kokubili ikhwalithi yokuphuma kanye ne-pellet. Ama-pellets ami agaywe kabusha manje abonisa amandla angcono emishini kanye nokubonakala okuthuthukisiwe okuthuthukisiwe. Ngingakwazi ukulawula usayizi we-pellet ngokunembe kakhudlwana, okungisiza ngihlangabezane nezimfuneko eziqinile zekhasimende. Ukulawulwa kwezinga lokushisa okuthuthukisiwe kugcina ukugeleza kokuncibilika kuzinzile, ngakho-ke ngithola ukukhubazeka okumbalwa kanye namapellets afanayo.

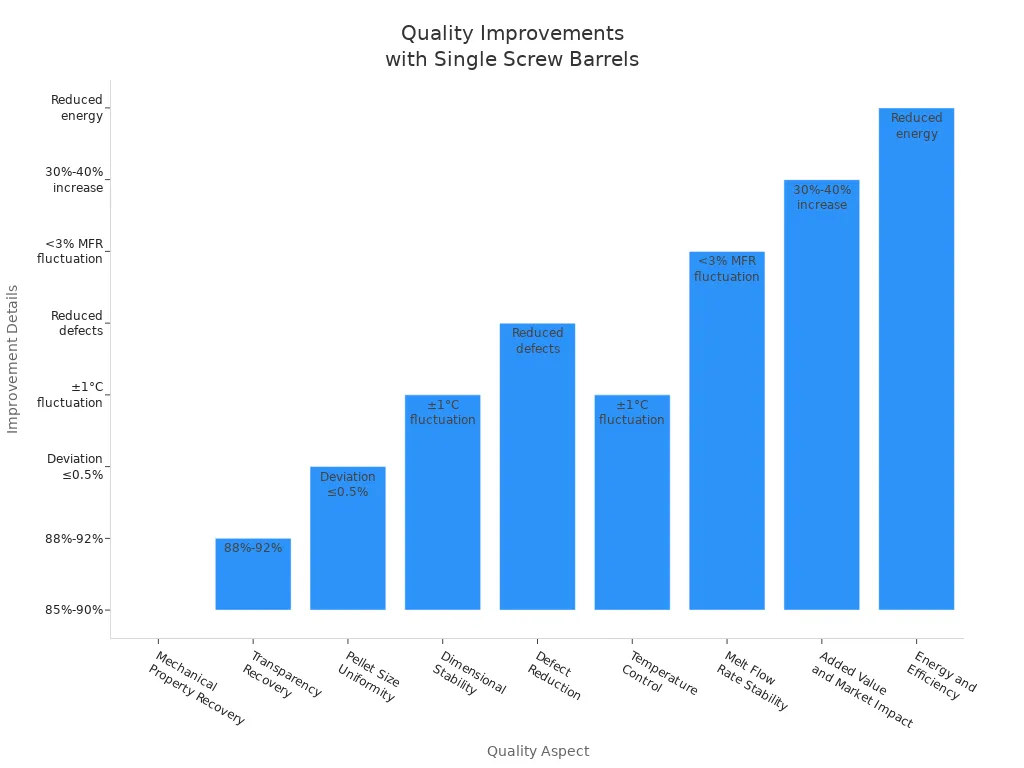

| Isimo Sekhwalithi | Imininingwane Yokuthuthukisa |

|---|---|

| Ukubuyiselwa Kwempahla Yemishini | 85% -90% izinga lokutakula, eliphakeme kakhulu kunemishini evamile |

| Ukubuyisela Obala | 88% -92% izinga lokutakula |

| I-Pellet Size Uniformity | Ukuchezuka kosayizi phakathi kuka-0.5% |

| Ukuzinza kweDimensional | Izinga lokushisa elilinganayo (±1°C ukushintshashintsha) liqinisekisa ukuzinza |

| Ukuncishiswa Kwesici | Ukungcola okumbalwa namaphutha |

| Ukulawula izinga lokushisa | Ukulawula okunezigaba ezinhlanu, ukushintshashintsha okungu-±1°C |

| I-Melt Flow Rate Stability | Ukushintshashintsha kwe-MFR ngaphansi kuka-3% |

| Inani Elingeziwe kanye Nomphumela Wemakethe | 30% -40% ukwenyuka kwenani elengeziwe |

| Amandla kanye Nempumelelo | Ukusetshenziswa kwamandla okuphansi, ukusebenza kahle okuphezulu |

Ukugcinwa Okuphansi kanye Nesikhathi Sokuphumula

Ngifunde ukuthi ukunakekelwa okuvamile kugcina umgqomo wami wesikulufa owodwa wokugaywa kabusha kwembudumbudu usebenza kahle. Ngilandela isimiso esiqinile sokunakekela futhi ngihlola umgqomo masonto onke. Ngihlala ngigcina izinga lokushisa nesivinini sesikulufu siqinile ukuze ngigweme ingcindezi emshinini. Impahla yepulasitiki ehlanzekile, ehlungiwe isiza ukuvikela ukulimala kokungcola. Ngihlanza futhi ngigcobe izingxenye ezihambayo ukuze ngimise ukugqwala nokungqubuzana. Uma ngibona izingxenye ezigugile, ngizishintsha ngokushesha. Ngikhetha imiphongolo eyenziwe ngama-alloys aqinile anezingubo ezikhethekile, njenge-nitriding, ukuze inwebe ukuphila kwayo.

- Ukuhlolwa kwemiphongolo yamasonto onkegcina okokusebenza kwami kusesimweni esiphezulu.

- Izinga lokushisa elilungile nezilungiselelo zokucindezela zivimbela ukuguga.

- I-feedstock ehlanzekile inciphisa umonakalo wangaphakathi.

- Ukuwohloka okujwayelekile kokuhlanza nokugcotshwa kuyayeka.

- Ukushintshwa kwengxenye esebenzayo kugwema isikhathi sokuphumula esingalindelekile.

- Ama-alloys aqinile nama-coatings enza umgqomo uhlale isikhathi eside.

Izitshalo ezilandela lezi zinyathelo zibika isikhathi esincane sokuphumula kanye nezindleko eziphansi zokulungisa. Ulayini wami wokugaya kabusha manje ususebenza kahle kakhulu futhi unokwethenjelwa.

Isifundo Esiyisibonelo: I-JT Single Screw Barrel in Multi-Plastic Recycling

Ngifake i-JT single screw barrel ukuze igaywe kabusha imbudumbudu esitshalweni sami ukuze iphathe amapulasitiki ahlukene njenge-PE, PP, ne-PVC. Izinto ezingagugi, njengeI-38CrMoAl ne-tungsten carbide, bandise ukuphila komgqomo. Manje ngisebenzisa imali encane ekulungiseni nasekuthengeni okunye. Ulayini wami wokukhiqiza awuvami ukuma, ngakho ngihlangabezana nezinsuku zami zokugcina zokulethwa. Ukusebenza okungaguquguquki kwe-JT single screw barrel yokugaya kabusha imbudumbudu kuthuthukise okukhiphayo kwami futhi kwehlise izindleko zami. Ngibona iziphazamiso ezimbalwa futhi kangconoikhwalithi ye-pellet, okungisiza ukuthi ngihlale ngincintisana emakethe.

Ngibona ukuthi imiphongolo yesikulufa eyodwa ixazulula kanjani izinkinga ezibalulekile zokugaywa kabusha. Okuhlangenwe nakho kwami kubonisa ikhwalithi engcono yokuncibilika, ukuxubana, nokuzinza kwenqubo. Ngomphongolo wesikulufa esisodwa sokugaywa kabusha kwembudumbudu, ngifinyelela ukusebenza kahle okuphezulu nokuthembeka. Lokhu kuthuthukiswa kusekela imisebenzi yokuhlanza, izindleko eziphansi, futhi kungisize ngihlangabezane nezidingo ezikhulayo zemboni zokugaywa kabusha kwepulasitiki okuzinzile.

FAQ

Imaphi amapulasitiki engingawacubungula ngomgqomo wesikulufa esisodwa se-JT?

Ngiyakwazi ukucubungula amapulasitiki amaningi, okuhlanganisa i-PE, PP, PS,I-PVC, i-PET, i-PC, ne-PA. Umphongolo uvumelana nezinto ezihlukene ukuze ugaywe kabusha ngendlela efanele.

Ngikwehlisa kanjani ukuguga emgqonyeni wami wesikulufa?

Ngisebenzisa imiphongolo eyenziwe ngama-alloys aqinile ane-nitrided noma i-bimetallic coatings. Ukuhlanza njalo nezilungiselelo ezifanele zingisiza ngelule impilo yomgqomo futhi ngigcine ukusebenza kuphezulu.

Kungani kubalulekile ukuncibilikisa i-homogenization ekugayweni kabusha?

I-Melt homogenization inginika ama-pellets afanayo. Ngibona amaphutha ambalwa namandla omkhiqizo angcono. Ukuxuba okungaguquguquki kungisiza ukuthi ngihlangabezane nezindinganiso zekhwalithi nezidingo zekhasimende.

Isikhathi sokuthumela: Aug-21-2025