Umgqomo wesikulufu sokubumba umjovo wepulasitiki udlala indima enkulu ekulolongeni ikhwalithi yokuncibilika nesivinini sokukhiqiza. Onjiniyela bagxile ku-Umjovo wokubumba umjovodesign ukukhulisa ukusebenza. Basebenzisa izinto ezahlukene ukuzeUmshini Owodwa wesikulufa wePlastiki ExtruderfuthiUmshini Owodwa Wokukhipha Isikulufu. Inketho ngayinye isiza imishini ukucubungula amapulasitiki kangcono.

I-Plastic Injection Molding Screw Barel Isakhiwo kanye nokusebenza

Izinhlobo Zemigqomo: I-Bimetallic vs. Integral

Ukukhetha uhlobo olufanele lomgqomo kungenza umehluko omkhulu endleleni aI-Plastic Injection molding screw barreluyayenza. Imiphongolo ye-Bimetallic isebenzisa isisekelo sensimbi esiqinile esinomugqa oqinile we-alloy ngaphakathi. Lo mklamo wonga izinto ezibalulekile futhi uvumela abakhiqizi ukuthi bashintshe ulayini osugugile kuphela, okwenza ukulungiswa kube lula futhi kungabizi kakhulu. Ukulingana phakathi kolwelwesi kanye nomgqomo kufanele kucace ukuze kugcinwe ukushisa kugeleza kahle futhi kuvimbele ukunyakaza. Imiphongolo ye-Bimetallic isebenza kahle ekucubunguleni amapulasitiki abrasive noma aqinisiwe ngoba amelana nokuguga futhi ahlala isikhathi eside.

Imiphongolo ehlanganisiwe yenziwa njengesiqephu esisodwa. Lokhu kubanika ukunemba okuphezulu ngisho nokusabalalisa ukushisa eduze komgqomo. Benza kube lula ukufaka nokugcina amasistimu okushisa kanye nokupholisa. Kodwa-ke, badinga izilawuli eziqinile zokukhiqiza ukugcina ikhwalithi iphezulu. Uma uqhathanisa kokubili, imiphongolo ehlanganisiwe inikeza ukugcinwa okulula nokushisa okufanayo, kuyilapho imiphongolo ye-bimetallic inikeza ukumelana okungcono kokugqoka kanye nokushintshwa kwengxenye elula.

| Isici sokuSebenza | I-Integral Barrel | I-Bimetallic Barrel |

|---|---|---|

| Ukwakha | Isiqephu esisodwa, ukunemba okuphezulu kokukhiqiza | I-Base barrel ene-alloy steel bushing eshintshwayo |

| Ukusabalalisa Ukushisa | Ukusabalalisa ukushisa okufanayo ku-axis yomgqomo | Ukushisa kuyagcinwa uma ukulingana kwe-bushing kunembile |

| Gqoka Ukumelana | Ukumelana nokugqoka okujwayelekile | Ukumelana nokugqokwa okuthuthukisiwe ngenxa ye-alloy steel lining |

| Isondlo | Ukufakwa nokugcinwa kalula kwamasistimu okushisa/okupholisa | I-bushing eshintshekayo ivumela ukushintshwa kwengxenye kube lula |

| Ukusetshenziswa Kwempahla | Idinga ukunemba okuphezulu nekhwalithi yezinto ezibonakalayo | Ilondoloza izinto ezibalulekile ngokusebenzisa insimbi ye-alloy kuphela kulwelwesi |

Imiphongolo ye-Bimetallic ivame ukuhlala isikhathi eside kunemiphongolo ehlanganisiwe, ikakhulukazi lapho icubungula izinto ezinzima. Idizayini yabo inciphisa isikhathi sokuphumula kanye nezindleko zokushintshwa, okusiza ukugcina ukukhiqiza kusebenza kahle.

I-Screw Geometry: I-L/D Ratio, I-Compression Ratio, ne-Flight Design

I-geometry ye-isikulufu ngaphakathi kombhobho wesikulufu wokubumba wePlastiki Umjovobobunjwa indlela amapulasitiki ancibilika futhi axube ngayo. Isilinganiso se-L/D, esiqhathanisa ubude besikulufu nobubanzi baso, sithinta ukuncibilika okufanayo nokuxutshwa. Isikulufu eside (isilinganiso esiphezulu se-L/D) sinikeza ipulasitiki isikhathi esengeziwe sokuncibilika nokuxutshwa, okuthuthukisa ikhwalithi yomkhiqizo. Kodwa-ke, uma isikulufu siside kakhulu, singabangela ukuwohloka kokushisa, ikakhulukazi ngamapulasitiki angezwani nokushisa. Izinto ezifana ne-PVC ne-POM zidinga izikulufu ezimfishane ukuze zigweme ukulimala, kuyilapho amapulasitiki agcwele ingilazi noma anokubona okuphezulu ahlomula ngezikulufu ezinde nezindawo zokuxuba eziqinisiwe.

- Izinto ezinokuzinza okuhle kwe-thermal zisebenzisa izikulufu ezinde ukuze kuxutshwe kangcono.

- Amapulasitiki azwela ukushisa adinga izikulufo ezimfushane noma imiklamo yentambo ekhethekile.

- Izikulufu zenhloso evamile (L/D ~20:1) zifanelana namapulasitiki avamile kodwa zingabonisa ukuhluka kombala.

- Izikulufu zokuvimbela (L/D ~24:1) zithuthukisa ukuxutshwa kwamapulasitiki aqinisiwe.

- Izikulufu zokuhlukanisa (L/D ~18:1) zisiza izinto ezizwela ukushisa zigweme ukonakala.

- Izikulufu zokuxuba (L/D ~22:1) zihlinzeka ngokuncibilika okufanayo kumapulasitiki akhethekile.

Isilinganiso sokucindezela sikala ukuthi isikulufu sicindezela kangakanani ipulasitiki. Amapulasitiki ane-viscosity ephezulu adinga isilinganiso esiphezulu sokucindezela ukuze ancibilike futhi axube kahle. Ukulungisa isilinganiso sokuminyanisa kusiza ukulinganisela kokuphumayo kanye nekhwalithi yomkhiqizo. Abakhiqizi bavame ukuqapha futhi bathuthukise idizayini yesikulufu ukuze ifane nezidingo zezinto ezibonakalayo.

Idizayini yendiza ekulufa nayo ibalulekile. Izikulufu ezilungiselelwe i-Rheologically zithuthukisa ikhwalithi yokuncibilika ngokufanisa ukuziphatha kokugeleza kwe-polymer. Amasistimu okulethwa kwe-Melt alawulwayo asiza ukulawula izinga lokushisa elincibilikayo kanye ne-viscosity, ukunciphisa ingozi yokuwohloka. Izikulufu ezixubayo nezikulufi zokuvimbela eziguqukayo zihlinzeka ngokuncibilika okufanayo futhi kuvimbele izindawo ezifile, okugcina ipulasitiki ingashisi ngokweqile noma ishintshe umbala.

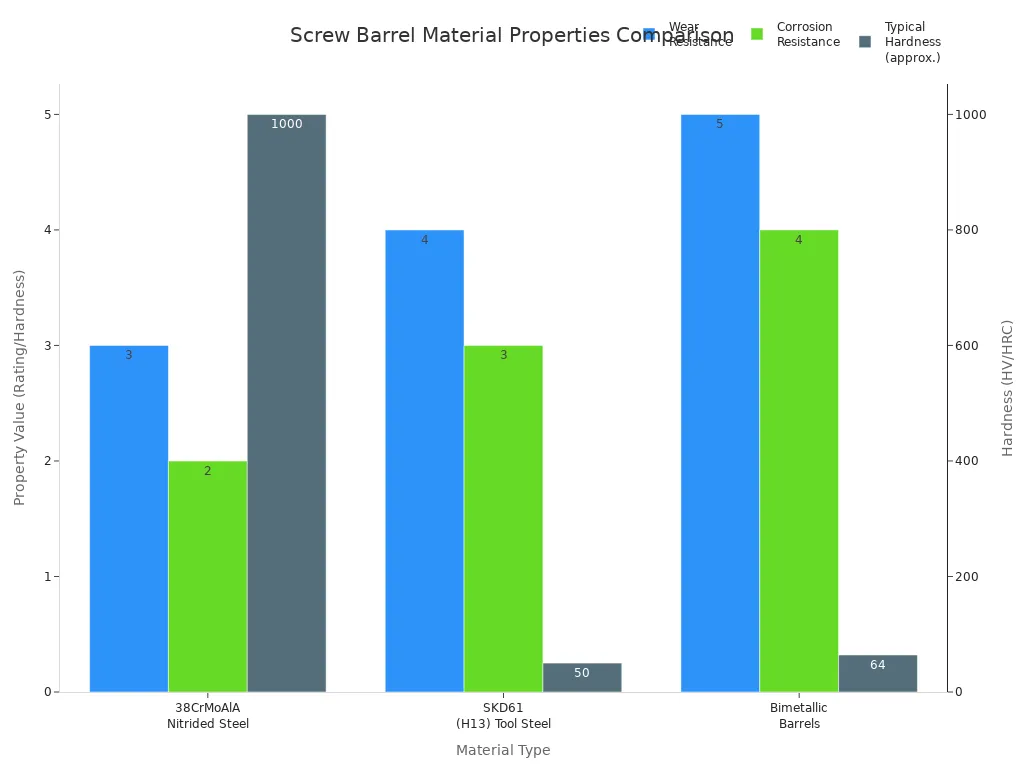

Ukwakhiwa Kwezinto Ezibalulekile kanye Nokwelapha Okungaphezulu

Izinto ezisetshenziswa ukwenza umphongolo wesikulufa wePlastiki Umjovo wokubumba zithinta ukuqina nokusebenza kwawo. Insimbi ye-nitrided inikeza ubulukhuni obuhle nokumelana nokugqoka kwamapulasitiki ajwayelekile. Imiphongolo ye-Bimetallic ihlanganisa isisekelo sensimbi ne-alloy liner, enikeza ukuguga okuhle kakhulu nokumelana nokugqwala kwamapulasitiki aqinile noma agcwele. Insimbi yamathuluzi inikeza amandla aphezulu nokumelana nokugqoka ezindaweni eziyingozi kakhulu.

| Uhlobo Lwezinto | Izakhiwo Ezibalulekile Nobuhle | Ububi Nemikhawulo | Best Izicelo |

|---|---|---|---|

| Insimbi ye-Nitrided | Ubulukhuni obuphezulu bobuso; ukumelana okuhle kokugqoka kwama-resin angagcwalisiwe; ezithengekayo | Ukumelana nokugqwala okungalungile; engafanelekile kuma-resin abrasive/chemical | Izinsalela zezimpahla ezifana ne-polyethylene, i-polypropylene |

| I-Bimetallic Barrels | Ukusekelwa kwensimbi nge-alloy liner; ukumelana nokugqwala okuhle kakhulu; ubude bempilo ende | Ibiza kakhulu; kungase kube overkill ukusetshenziswa jikelele | Amanayiloni agcwaliswe ingilazi, i-ABS enganqamuki ilangabi, i-PVC, ama-polymer anamandla |

| Ama-alloys Asekelwe ku-Nickel | Ukumelana nokugqwala okukhethekile; kuhle kuma-resins ane-halogenated ane-flame-retardant | Iqinile kancane kunama-alloys asekelwe ensimbi; ukumelana nokugqoka okuphansi | Ama-polymers anolaka lwamakhemikhali |

| Ama-Alloys Asekelwe Ensimbi | Ukuqina okuphezulu nokumelana nokugqoka | Ukumelana nokugqwala okuphansi kunama-alloys asekelwe ku-nickel | Ama-resin abrasive, agcwele kakhulu |

| Insimbi Yensimbi | ubulukhuni namandla angavamile; ukumelana nokugqoka okuphezulu | Izindleko eziphezulu; iyakwazi ukugqwala ngaphandle kokumbozwa | Izindawo ezigqokwa kakhulu, izinhlelo zokusebenza eziphuma phambili |

| Imiphongolo Ehlanganisiwe Ekhethekile | Izigqoko ezifana ne-tungsten carbide noma i-chrome plating ithuthukisa ukuguga nokumelana nokugqwala | Yengeza izindleko nobunkimbinkimbi; ukunamathela enamathela kuyahlukahluka | Izinhlelo zokusebenza ze-resin ngokwezifiso noma ezinolaka |

Ukwelapha okungaphezulu okufana ne-nitriding ne-chrome plating kuthuthukisa ukumelana nokugqokwa nokuphila isikhathi eside. I-Nitriding ingaphinda kabili noma kathathu impilo yesevisi yezikulufu nemiphongolo. I-Chrome plating inyusa ubulukhuni nokumelana nokugqwala, kodwa i-nitriding ivamise ukwenza kangcono ngaphansi kwezimo zokuhuzuka. Ukufafaza kwe-molybdenum kuhlanganiswe ne-nitriding kunikeza ukuvikeleka okwengeziwe. Ukusebenza kahle nokunakekela kusiza ukukhulisa lezi zinzuzo.

I-Feeding Port kanye ne-Venting Design

Idizayini yembobo yokudla ilawula ukuthi ipulasitiki ingena kanjani emgqonyeni. Ukulawula izinga lokushisa okuhle endaweni yokudla kugcina i-viscosity yezinto ingashintshi, esiza ukugcina ukugeleza nokuphakela okungaguquki. Izilayishi ze-vacuum kanye nezamukeli ze-hopper ziqinisekisa ukuthi impahla ihamba kahle emshinini, inciphisa ukungcoliswa nokuchitheka. Lokhu kusetha kugcina ikhwalithi yokukhiqiza iphezulu futhi nokudla kungashintshi.

- Izilayishi zevacuum zigibela ngqo emphinjeni womshini, zinciphisa ukungcoliswa.

- Abamukeli beHopper basebenzisa amandla adonsela phansi ukuze baphakele izinto, benze inqubo ibe lula.

Umklamo wokungenisa umoya nawo udlala indima ebalulekile. Izikulufu ze-vent zinezindawo ezikhethekile ezisusa umswakama kanye nokuguquguquka ngesikhathi sokucubungula. Lokhu kubalulekile ezintweni ze-hygroscopic namapulasitiki agaywe kabusha. Izimbobo zokungenisa umoya zivumela amagesi nomswakama ukuba kubaleke, kuvinjwe amaphutha nokugcina ikhwalithi yokukhipha umoya iphezulu.

Ithiphu: Imbobo yokuphakela efanele kanye nedizayini yokukhipha umoya isiza ekugcineni ukukhiqizwa okuzinzile kanye nokuthuthukisa ikhwalithi yomkhiqizo, ikakhulukazi uma usebenza ngamapulasitiki agaywe kabusha noma azwelayo.

Imiphumela Yokusebenza Ye-Plastic Injection Molding Screw Barrel Design

Melt Ikhwalithi kanye ne-Homogeneity

Umphongolo oklanywe kahle we-Plastic Injection molding screw usiza ukudala ukushelela nokuncibilika okulinganayo. Ijiyomethri yesikulufu, kuhlanganise nayoisilinganiso sokucindezelakanye nokuma kwezindawo zayo, ilawula ukuthi ama-pellets epulasitiki ancibilika futhi axube kanjani. Lapho isilinganiso sokucindezelwa sihambisana nempahla, ukuncibilika kugeleza ngokulinganayo. Lokhu kunciphisa izinkinga ezifana nama-splay marks noma ukuncibilika okungaphelele. Iindawo yokuphakelayoinyakazisa futhi ifudumale ama-pellets, indawo yokucindezela iyancibilika futhi icindezela into, futhi indawo yokulinganisa yenza isiqiniseko sokuthi ukuncibilika kuyalingana. Izici ezifana nokujula kwesiteshi nezigaba zokuxuba zisiza ukushisa kwesikulufu futhi zihlanganise ipulasitiki. Izikulufu zesithiyo zingahlukanisa ipulasitiki eqinile nencibilikisiwe, yenze ukuncibilika kusebenze kahle kakhulu nokonga amandla.

Uma ukuncibilika kufana, umkhiqizo wokugcina ubukeka ungcono futhi usebenza kangcono. Ukuxubana okungalungile kungabangela imicu yombala, izindawo ezibuthakathaka, noma izinguquko kusayizi wengxenye. I-melt homogeneity enhle isho ukukhubazeka okumbalwa kanye nezingxenye ezithembeke kakhulu. Ama-opharetha angaphinda asebenzise izinzwa ukuze abuke ikhwalithi encibilikayo futhi alungise izilungiselelo ukuze uthole imiphumela engcono.

- Ukuxuba okuncibilikisiwe okungalungile kubangela imichilo yombala namabala abuthaka.

- Ikhwalithi enhle yokuncibilika iholela kusayizi wengxenye engaguquki namandla.

- Ikhwalithi yokuncibilika incike kuzinga lokushisa lomphongolo, isivinini sesikulufu, nokucindezela okungemuva.

Qaphela: Ukugcina izinga lokushisa elincibilikayo lizinzile kanye nedizayini yesikulufu ehambisana nohlobo lwepulasitiki kusiza ukugwema amaphutha futhi kugcine ikhwalithi yomkhiqizo iphezulu.

Ukuxuba Ukusebenza Nesikhathi Somjikelezo

Ukusebenza kahle kokuxuba kuncike ekumeni kwesikulufu nezici ezikhethekile. Njengoba isikulufu siphenduka, siphusha futhi sigoqe ipulasitiki, sidale amandlagunda amabutho. Ukuxuba izigaba eduze kwethiphu, njengezikhonkwane noma izindiza ezivimbelayo, kusiza ukuhlanganisa ukuncibilika. Lesi senzo sisakaza umbala nezithasiselo ngokulinganayo, ngakho ingxenye yokugcina ibukeka ibushelelezi futhi ifana. Izikulufu zesithiyo zisebenzisa indiza yesibili ukuhlukanisa ipulasitiki encibilikisiwe nezinsimbi eziqinile, zisheshisa ukuncibilika futhi zivimbele izingcezu ezingancibilikisiwe.

- Isikulufa sejiyomethri silawula ukuthi ama-pellets anyakaza, ancibilike, futhi axube kanjani.

- Ukuxuba izigaba kudala ukunyakaza kwe-loop,hlanganisa ngaphezu kwama-95%wendaba ngokushesha.

- Izikulufu zesithiyo nemiklamo ekhethekile zisiza ekuhlakazeni umbala nezithasiselo.

Ukusebenza kahle kokuxuba kuphinde kuthinte isikhathi somjikelezo. Ukushesha nokuncibilika okukhulu kusho ukuthi umshini ungagijima imijikelezo eminingi ngesikhathi esincane. Ukusebenzisa izikulufu zesithiyo, izikulufu ezinkudlwana zobubanzi, noma izisele ezijulile kukhulisa isivinini sokwenza ipulasitiki. Ukuphakamisa isivinini sesikulufu (uma kuphephile okokusebenza) kanye nokunciphisa ingcindezi yasemuva nakho kunganciphisa izikhathi zomjikelezo. Amasistimu okushisisa athuthukisiwe nawokupholisa agcina umgqomo usezingeni lokushisa elifanele, esiza izingxenye ukuthi ziphole ngokushesha futhi zigcine ukukhiqiza kuhamba.

- Idizayini ye-screw barrel ethuthukisiwe ivimbela ukuvala nokubambezeleka.

- Amasistimu okushisisa nawokupholisa anembile asiza izingxenye ukuthi ziqine ngokushesha.

- Izinto ezihlala isikhathi eside kanye nezingubo zokugqoka zinciphisa isikhathi sokulungiswa.

Gqoka Ukumelana Nokunakekela

I-Wear iyinkinga enkulu yanoma yimuphi umphongolo wesikulufa we-Plastic Injection. Ama-abrasive fillers, amapulasitiki abolayo, kanye nokugijima okude kokukhiqiza kungaguga isikulufu nomgqomo. Izinhlobo zokugqoka ezijwayelekile zifaka ukunamathela okunamathelayo, ukuguguleka, nokugqwala. Isibonelo, ukuguguleka kwenzeka uma izigcwalisi eziqinile njengefiber yengilazi zihlikihla ensimbi. Ukugqwala okubolayo kuvela kumakhemikhali akupulasitiki njenge-PVC.

| Gqoka iMechanism | Incazelo | Idizayini Amasu Okunciphisa |

|---|---|---|

| I-Adhesive Wear | Izingxenye zensimbi zokuthintana nezokudlulisa. | Sebenzisa ama-alloys e-hardfacing, hlola ukuthola amaphuzu, qinisekisa ukuhambisana kwezinto ezibonakalayo. |

| I-Abrasive Wear | Isenzo sokugunda kusuka kuma-pellets noma ama-filler. | Sebenzisa ama-alloys aqinile, gwema ama-filler abrasive, gcina i-feedstock ihlanzekile. |

| Izingubo Ezidlayo | Ukuhlasela kwamakhemikhali okuvela kumapulasitiki athile. | Sebenzisa izinto ezimelana nokugqwala, gwema amakhemikhali anokhahlo. |

| Izinkinga Zokuqondanisa | Ukungalungi kahle kubangela ukukhuhla nokuguga okungalingani. | Qinisekisa ukuqondisa nokuqondanisa okufanele. |

Ukukhethwa kwezinto ezibonakalayo kanye nokwelashwa kwendawo kwenza umehluko omkhulu. I-nitriding ewuketshezi inyusa ubulukhuni bobuso kanye nokumelana nokugqoka. Imiphongolo ye-Bimetallic enemigqa ekhethekile ihlala isikhathi eside, ikakhulukazi ngamaplastiki aqinile. Ukuhlola okuvamile nokugcinwa kokuvikela, njengokuhlanza nokuhlola ukuqondanisa, kusiza ukubamba izinkinga kusenesikhathi. Izembatho ezithuthukisiwe nezinto ezintsha zinganweba ukuphila komgqomo kuze kufike ku-40%, kwehlise izindleko zokulungisa futhi kunciphise isikhathi sokuphumula.

- Imvamisa yokulungisa incike ezintweni zomgqomo kanye nama-coatings.

- Ukugcinwa kokuvimbela nokuhlolwa okuvamile kwandisa impilo yomgqomo.

- Ukwelapha okuseqophelweni eliphezulu kunciphisa ukulungiswa nokushintshwa.

Ukuzivumelanisa nezimo Ezisetshenziswa Ezihlukene Nezinhlelo Zokusebenza

Idizayini ye-screw barrel eguquguqukayo ivumela abakhiqizi ukuthi bacubungule izinhlobo eziningi zamapulasitiki. I-Screw geometry, njengobude, ukuphakama, nokujula kwesiteshi, ingashintshwa ukuze ivumelane nezinto ezihlukahlukene. Inhloso evamile, izithiyo, nezikulufi zokuxuba ngasinye sisebenza kangcono ngamapulasitiki athile. Amasistimu okupholisa, njengamashaneli amanzi, agcina umgqomo usezingeni lokushisa elifanele lento ngayinye.

- Idizayini yesikulufu kanye nejometrihlanganisa amapulasitiki ahlukene.

- Amasistimu okupholisa avimbela ukushisa ngokweqile.

- Ama-alloys aphezulu kanye nama-coatings aphatha izimo ezinzima.

Imiklamo evumelana nezimo futhi yenza kube lula ukushintsha phakathi kwemisebenzi. Izici ezifana nama-adaptha anqamula ngokushesha nama-screw pushers asiza opharetha ukuthi baguqule izikulufu ngokushesha. Izilawuli zenqubo eguquguqukayo zisebenzisa izinzwa nokufunda komshini ukulungisa izilungiselelo ngesikhathi sangempela. Lokhu kunciphisa izinguquko ezenziwa mathupha futhi kusheshise ukushintshwa, ukuze ukukhiqizwa kungashintsha kusuka kokunye noma umkhiqizo kuya komunye ngesikhathi esincane sokuphumula.

Ithiphu: Imiklamo ye-screw barrel eguquguqukayo isiza izimboni ukuphatha izinhlobo eziningi zamapulasitiki futhi zishintshe imisebenzi ngokushesha, zigcine ukukhiqiza kuvumelana nezimo futhi kusebenza kahle.

Ukuxazulula Izinkinga Zokusebenza Okujwayelekile

Ngisho nomklamo omuhle kakhulu, izinkinga zingenzeka. Izinkinga ezivamile zihlanganisaukugqoka ngokweqile, izinkinga zezinga lokushisa, ukuvinjwa, umsindo, namaphutha okuxuba imibala. Inkinga ngayinye inezimbangela zayo kanye nezixazululo.

| Inkinga yokusebenza | Incazelo kanye Nezimpawu | Izimbangela Nezixazululo |

|---|---|---|

| Ukugqoka Okudlulele | Ukuvuza kwezinto, izinga eliphansi, izinga lokushisa eliphezulu, umsindo | Sebenzisa imiphongolo ye-bimetallic, ama-alloys aqinile, ukuhlanza okuvamile, ukuqondanisa okufanele |

| Ukulawulwa kwezinga lokushisa | Ukushintsha umbala, ukushabalalisa, amabhamuza, i-warping | Hlukanisa umgqomo ube yizindawo, sebenzisa izinzwa, ukushisa kancane kancane, amajakhethi okufakwa ngaphakathi |

| Ukuvinjwa kanye nokwakha-Up | Ukucindezela okuphezulu, ukugeleza okungalungile, amachashaza amnyama | Hlanza ngezinhlanganisela zokuhlanza, isivinini esifanelekile sesikulufu, umgqomo wokuvala ngesikhathi sokuphumula |

| Umsindo noma Ukudlidliza | Imisindo ephezulu, ukudlidliza, ukungqubuzana | Hlola ukuqondanisa, ama-bearings, sebenzisa i-vibration damping, hlukanisa izingxenye |

| Ukuxuba Umbala/Ukungcola | Imivimbo yombala, ama-shades angahambisani, ukungcola | Sebenzisa izinhlanganisela zokuhlanza, ukuhlanza okuvamile, thuthukisa ukwakheka kwesikulufa, imishini yokuvala uphawu ngesikhathi sokuvalwa |

Ama-opharetha angaxazulula izinkinga eziningi ngokulandela izinyathelo ezimbalwa ezibalulekile:

- Lungiselela ukucushwa kwesikulufu kanye nezindawo zokushisa zomgqomo.

- Gada futhi ulungise amazinga okushisa kanye nesivinini sesikulufu.

- Linganisa okuphakelayo futhi uvimbele ukuhlanganisa impahla.

- Hlola izikulufu nemiphongolo ukuthi azigugile, ikakhulukazi ezindaweni ezinengcindezi ephezulu.

- Sebenzisa ukulungiswa okubikezelwayo ukuze uhlele ukulungisa nokunciphisa isikhathi sokuphumula.

- Gcina isikulufu esiyisipelefuthi ulungise izikhathi ezimbalwa kuphela.

- Qeqesha abaqhubi ukuthi babone izimpawu eziyisixwayiso kusenesikhathi.

Qaphela:Ukuhlanza njalo, ukugcotshwa ngendlela efanele, nokuqapha ngokucophelelaukusiza ukugcina umgqomo wesikulufu wePlastiki Umjovo wokubumba usebenza kahle futhi welule impilo yawo.

Ukuthuthukisa ukwakheka komgqomo wesikulufa wePlastiki Umjovo wokubumba kuthuthukisa ikhwalithi yokuncibilika nempilo yemishini. Lapho abakhiqizi bekhetha i-uhlobo lomgqomo ongakwesokudla, ijometri yesikulufu, nezinto zokwakha, babona ukugeleza okushelelayo, ukuxubana okungcono, namaphutha ambalwa. Ukunakekelwa njalo, okuhlanganisa ukuhlanzwa nokuhlolwa, kugcina imishini isebenza kahle futhi kwehlisa nezindleko.

FAQ

Iyini inzuzo eyinhloko yomphongolo wesikulufa se-bimetallic?

Imiphongolo ye-Bimetallic imelana nokugqoka kusuka kumapulasitiki aqinile. Zihlala isikhathi eside futhi zinciphisa isikhathi sokunakekelwa.

Kufanele opharetha bahlole kangaki umgqomo wesikulufu?

Ama-opharetha kufanele ahlole umphongolo wesikulufa njalo ngenyanga. Ukuhlola okuvamile kusiza ukubamba ukuguga kusenesikhathi futhi kugcine imishini isebenza kahle.

Ingabe umphongolo owodwa wesikulufa ungasebenza nezinhlobo eziningi zamapulasitiki?

| Uhlobo Lomgqomo | Ukuzivumelanisa nezimo |

|---|---|

| Inhloso Ejwayelekile | Kuhle |

| Umgoqo | Kuhle kakhulu |

| Ukuxuba | Kuhle kakhulu |

Umgqomo oklanywe kahle ungaphatha amapulasitiki amaningi, kodwa ezinye izinto zidinga izici ezikhethekile.

Isikhathi sokuthumela: Aug-25-2025