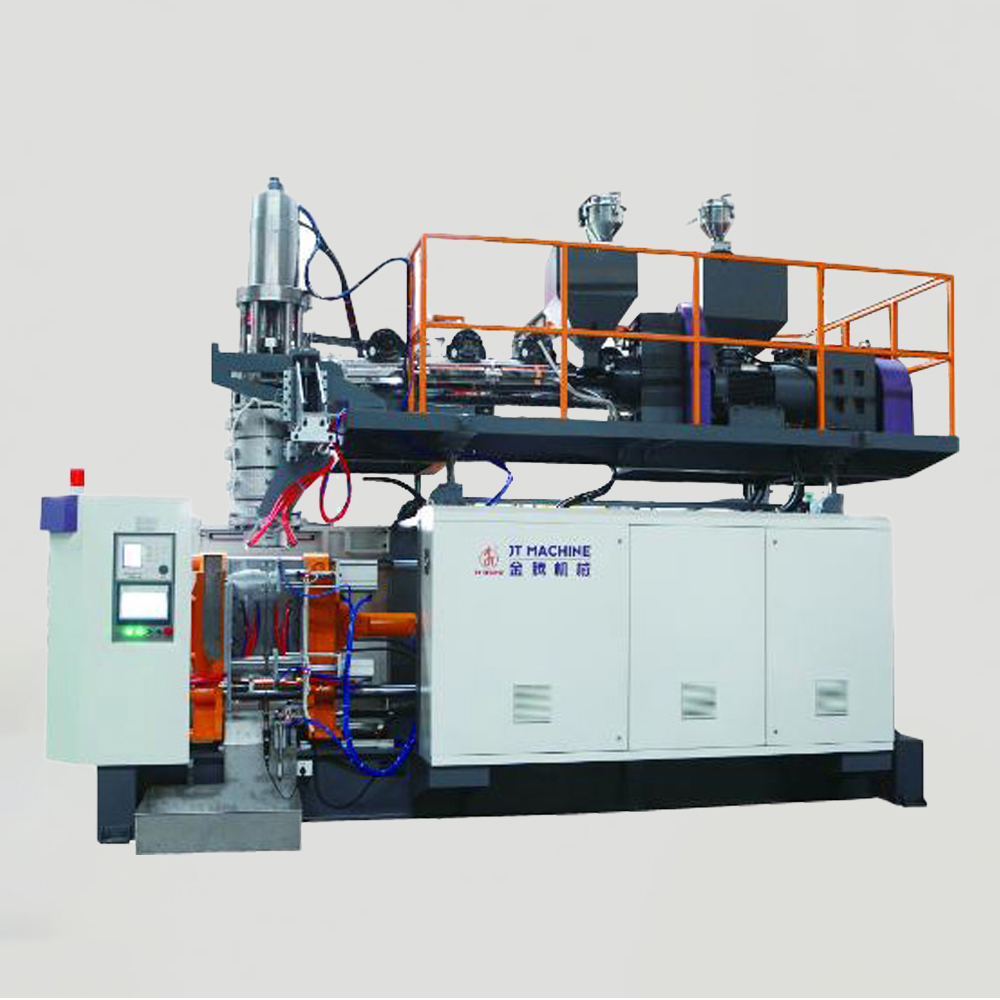

Imishini ethuthukisiwe yokufutha amabhodlela iguqule isimo sokukhiqiza. Manje izimboni zithembele kule mishini ukuze zihlangabezane nezidingo ezikhulayo zokukhiqiza okunesivinini esikhulu, okusekelwe ngokunemba. Izici ezifana nokuzenzakalela kanye nokuqapha kwesikhathi sangempela kuqinisekisa ikhwalithi engaguquki kuyilapho kunciphisa izindleko. Amamodeli anesivinini esikhulu angakhiqiza phakathi kwamabhodlela angu-500 kuya kwayi-1,000 ngehora, abhekane nesidingo esikhulayo somkhakha weziphuzo ukuze uthole izixazululo eziphumelelayo. Ukwengeza, ukushintshela ekufakweni okungasindi kuholele abakhiqizi, okuhlanganisaIzimboni zomshini wokufutha ibhodlela le-PP, ukwamukela lobu buchwepheshe ngokuhlukahluka kwabo. Ngaphezu kwalokho, ukuhlanganiswa kwe-aI-PVC foam board extrusion linekuthuthukisa amakhono okukhiqiza, kuyilapho aI-extruder yesikulufu esisodwa sesikhwama sikadotiukukhiqiza kuhambisana nezinhlelo zokusebenza ezihlukene zale mishini ethuthukisiwe.

Isebenza Kanjani Imishini Yokuvuthela Amabhodlela

Preform Creation and Heating

Inqubo yokufutha ibhodlela iqala ngokudalwa nokushisa kwama-preforms. Lawa ma-preforms, ngokuvamile enziwe ngezinto ezifana ne-PET, ayashiswa ukuze afinyelele ukugcwaliseka okufanelekile kokubunjwa. Imishini ethuthukisiwe yokufutha amabhodlela isebenzisa imisebe ye-infrared noma ukujikeleza komoya oshisayo ukushisisa ngokulinganayo ama-preforms. Lokhu kuqinisekisa ukufana kwezinga lokushisa lezinto ezibonakalayo, okubalulekile ekugcineni ikhwalithi engaguquki phakathi nezigaba ezilandelayo.

Uhlelo lokushisa emishinini yesimanje yakhelwe ukunemba. Ama-opharetha angalawula izinga lokushisa ukuze kuncishiswe amaphutha, ngezilungiselelo ezinconyiwe ngokuvamile ezingaba ngu-45°C (113°F). Leli zinga lokulawula linciphisa imfucuza yezinto ezibonakalayo futhi liqinisekisa ukuthi ama-preforms alungiselelwe ngokwanele ukwelula nokushaywa. Ngemuva kokushisa, ama-preforms ashintsha ngokukhululekile aye esigabeni esilandelayo, lapho abunjwa abe amabhodlela.

Ukubumba kanye Ukubunjwa

Uma sekushisiwe, ama-preforms afakwa ezikhunjini ezichaza ukuma kokugcina nosayizi wamabhodlela. Inqubo yokubumba ihlanganisa izingxenye eziningana ezibalulekile ezisebenza ngokuvumelana ukuze kuqinisekiswe ukunemba nokusebenza kahle.

- Iyunithi yokushisisa: Ithambisa i-preform ukuze iphenduleke.

- I-Mold Clamping System: Ivikela isikhunta futhi iqondanise i-preform yokubunjwa okunembayo.

- Elule futhi EphephethaIndlela: Yelula i-preform ethambile ngenkathi umoya ocindezelwe uyiphephula esikhunjeni, yenza ibhodlela.

Umshini wokufutha amabhodlela wochungechunge lwe-JT uyaphumelela kulesi sigaba ngenxa yezinhlelo zawo zokulawula ezithuthukile kanye nomklamo oqinile. Izici ezifana nomsebenzi wokuphakamisa inkundla zithatha ubude obuhlukahlukene bokufa, okuvumela ukukhiqizwa kwemiklamo ehlukahlukene yamabhodlela. Ukwengeza, uhlelo lomshini olulinganayo lwe-hydraulic luqinisekisa izenzo ezibushelelezi nezisheshayo, zithuthukisa ukukhiqiza.

| Isakhi | Umsebenzi |

|---|---|

| Iyunithi yokushisisa | Ithambisa i-preform isebenzisa imisebe ye-infrared ukuze isebenziseke ngesikhathi sokubumba. |

| I-Mold Clamping System | Ivikela isikhunta endaweni futhi iqondanise i-preform yokwakheka kwamabhodlela okunembile. |

| Elule futhi Ephephetha | Yelula i-preform ethambile futhi ifuthe umoya kuyo ukuze ilolonge ibhodlela ngokunembile. |

| Isistimu Epholile | Ipholisa ngokushesha ibhodlela ukuze ligcine umumo nobuqotho besakhiwo ngemva kokubunjwa. |

| Uhlelo Lokukhipha | Ikhipha ibhodlela eliqediwe esikhunjeni isebenzisa izingalo zemishini noma umfutho womoya ngaphandle kokulimala. |

Lesi sigaba sigqamisa ukuguquguquka kwemishini yokufutha amabhodlela, engamukela osayizi bamabhodlela abahlukahlukene kanye nokwakheka ukuze kuhlangatshezwane nezidingo zemakethe ezahlukahlukene.

Ukupholisa kanye Nenqubo Yokukhipha

Isigaba sokugcina sibandakanya ukupholisa nokukhipha amabhodlela. Ukupholisa okusheshayo kuqinisa ukwakheka kwebhodlela, kuqinisekise ukuthi ligcina ukwakheka kwalo futhi lihlangabezana nezindinganiso zekhwalithi. Imishini ethuthukisiwe efana nochungechunge lwe-JT isebenzisa inhlanganisela yezinhlelo zokupholisa komoya namanzi ukusheshisa le nqubo. Izikhathi zokupholisa zingasukela kumasekhondi angu-1.5 kuye kumasekhondi angu-20, kuye ngosayizi webhodlela nokokusebenza.

Ngemuva kokupholisa, amabhodlela akhishwa ekubunjweni kusetshenziswa izingalo zemishini noma ukucindezela komoya. Lesi sinyathelo sibalulekile ekugcineni isivinini sokukhiqiza nokuvimbela ukulimala emikhiqizweni ephelile. Uchungechunge lwe-JT luhlanganisa isistimu yokugcoba okuzenzakalelayo kanye nesistimu ye-cylinder drive ukuze kukhishwe kahle, kuncishiswe izidingo zokunakekelwa kanye nesikhathi sokuphumula sokusebenza.

| Inqubo | Incazelo |

|---|---|

| Ukupholisa | Ukupholisa okusheshayo kuqinisa ukwakheka kwebhodlela, kuqinisekisa ukugcinwa komumo kanye nemijikelezo yokukhiqiza esheshayo. |

| Ukukhishwa | Amabhodlela ayakhishwa ngemva kokupholisa futhi alawulwa ikhwalithi ukuze ahlangabezane namazinga okukhiqiza. |

Ngokuhlanganisa lezi zici ezithuthukisiwe, imishini yokufutha amabhodlela ithuthukisa isivinini sokukhiqiza futhi iqinisekise ikhwalithi engaguquki, ibenze babaluleke kakhulu ekukhiqizeni kwesimanje.

Izinzuzo Eziyinhloko Zemishini Yokuvuthela Amabhodlela

Ukwenyuka Kwesivinini kanye Nempumelelo Yokukhiqiza

Imishini yesimanje yokufutha amabhodlela iguqule izinqubo zokukhiqiza ngokuthuthukisa kakhulu isivinini nokusebenza kahle. Le mishini isebenzisa izindlela ezithuthukisiwe, ezifana nezinhlelo eziqhutshwa yi-servo kanye nobuchwepheshe be-hydraulic obulinganayo, ukwenza lula ukusebenza. Umshini wokufutha amabhodlela wochungechunge lwe-JT uyisibonelo salokhu kuqanjwa kabusha, ukhiqiza imikhiqizo yepulasitiki engenalutho ngokunemba okuphawulekayo nesivinini.

Isivinini sokukhiqiza siyahlukahluka kuye ngendlela esetshenziswayo. Ubuchwepheshe be-Blow blow bufinyelela kumabhodlela angama-200 ngomzuzu, kuyilapho izindlela zokucindezela ukucindezela zihluka phakathi kwamabhodlela angama-50 kuya kwayi-100 ngomzuzu. Lokhu kuguquguquka kuvumela abakhiqizi ukuthi bakhethe indlela efaneleke kakhulu yezidingo zabo ezithile.

| Indlela | Isivinini Sokukhiqiza (amabhodlela ngomzuzu) |

|---|---|

| Vuthela Vuthela | 200 |

| Cindezela Vuthela | 50-100 |

Ukuhlanganiswa kokuzenzakalelayo kuthuthukisa ukusebenza kahle. Izici ezifana namasistimu okugcoba okuzenzakalelayo nokuqapha kwesikhathi sangempela kunciphisa isikhathi sokuphumula kanye nezidingo zokunakekelwa. Lokhu kuthuthukiswa kwenza abakhiqizi bakwazi ukuhlangabezana nezidingo zevolumu ephezulu ngenkathi begcina okukhiphayo okungashintshi.

Ithiphu: Ukutshala imali emishinini yokufutha amabhodlela enesivinini esikhulu kungasiza amabhizinisi ukukala ukukhiqizwa ngaphandle kokubeka engcupheni ikhwalithi.

Ikhwalithi Engaguquki Nethembekile

Ukuvumelana kwekhwalithi yomkhiqizo kuwuphawu lwemishini ethuthukisiwe yokufutha amabhodlela.Ubunjiniyela bokunembaiqinisekisa ukuthi ibhodlela ngalinye lihlangabezana nezindinganiso eziqinile ze-dimensional, linciphisa amaphutha kanye nemfucuza. Uchungechunge lwe-JT luhlanganisa ubuchwepheshe bokuvuthela i-servo stretch, okuthuthukisa ikhwalithi yamabhodlela ngokunciphisa okungahambi kahle.

Amasistimu okushisa e-infrared adlala indima ebalulekile ekugcineni ukufana. Lawa masistimu asabalalisa ukushisa ngokulinganayo kuwo wonke ama-preforms, avimbele izimpawu zokucindezeleka nezindonga ezingalingani. Le ndlela yokucophelela iphumela emabhodleleni angagcini nje ngokubukeka kodwa futhi azwakalayo ngokwesakhiwo.

| Isici | Umthelela Ekuhambisaneni Kwekhwalithi |

|---|---|

| Ubunjiniyela bokunemba | Iqinisekisa amabhodlela ekhwalithi ephezulu anobukhulu obungaguquki |

| I-Servo Stretch Blowing | Ithuthukisa ikhwalithi yamabhodlela, inciphisa amaphutha |

| Ukushisisa kwe-infrared | Inciphisa izimpawu zokucindezeleka nezindonga ezingalingani |

Abakhiqizi ezimbonini ezifana nokupakishwa kokudla kanye nemithi bathembele kule mishini ukukhiqiza amabhodlela ahambisana nezindinganiso eziqinile zokulawula. Uchungechunge lwe-JT lugqama ngekhono lalo lokuletha imiphumela ethembekile kuzo zonke izinhlelo zokusebenza ezihlukene.

Qaphela: Ikhwalithi engaguquki inciphisa isidingo sokusebenza kabusha, ukonga isikhathi nezinsiza.

Ukusebenza kahle kwamandla kanye nokonga izindleko

Ukusebenza kahle kwamandla kuyisici esibalulekile ekukhiqizeni kwesimanje. Imishini ethuthukisiwe yokufutha amabhodlela, njengochungechunge lwe-JT, ihlanganisa nobuchwepheshe bokulondoloza amandla obunciphisa izindleko zokusebenza. Amamotho efrikhwensi aguquguqukayo kanye nezinhlelo ezilawulwa yi-servo-hydraulic hydraulic zikhulisa ukusetshenziswa kwamandla, okwenza le mishini ibe ngu-15% kuya ku-30% wonga amandla ngaphezu kwamamodeli endabuko.

| Incazelo yobufakazi | Imininingwane |

|---|---|

| Umthelela Wokusebenzisa Amandla | Imishini evamile idla amandla angu-25% ngaphezulu kunamamodeli ayingxube, okuholela ezindlekweni zokusebenza eziphezulu. |

| Izindleko zikagesi | Izindleko zikagesi zibalelwa ku-20% wezindleko zokukhiqiza sezizonke, okugqugquzela ukutshalwa kwezimali emishinini eyonga amandla. |

| Ukunciphisa Ukusetshenziswa kwamandla | Imishini emisha inganciphisa ukusetshenziswa kwamandla ngo-15%, okunomthelela ngqo ezindlekweni zokusebenza. |

Ukwengeza, ukushintshela ezindleleni ezisimeme kuqhuba ukwamukelwa kwemishini esekela amapulasitiki angaboli. Cishe u-35% wamamodeli amasha aklanyelwe ukuhlalisa izinto ezingasetshenziswa kabusha, ezihambisana nezinjongo zemvelo.

- Ukusetshenziswa kweamasistimu awonga ugesikunciphisa izindleko zikagesi, ezibalela ingxenye enkulu yezindleko zokukhiqiza.

- Abakhiqizi abasebenzisa ukukhiqizwa kwamabhodlela okusimeme bayazuza ekusebenziseni amandla okuphansi kanye nomthelela oncishisiwe kwemvelo.

Ngokubeka phambili ukusebenza kahle kwamandla, amabhizinisi angakwazi ukuzuza ukonga isikhathi eside kuyilapho enikela emizamweni yokusimama komhlaba.

I-callout: Imishini yokufutha amabhodlela eyonga amandla ayigcini nje ngokunciphisa izindleko kodwa futhi isekela izinqubo zokukhiqiza ezivumelana nemvelo.

Intuthuko Yezobuchwepheshe Emishini Yokuvuthela Amabhodlela

I-Automation kanye ne-Smart Control Systems

I-Automation isiphenduke isisekelo semishini yesimanje yokufutha amabhodlela, iguqula izinqubo zokukhiqiza ngokunemba okungenakuqhathaniswa nokusebenza kahle. Amasistimu okulawula ahlakaniphile, anikwa amandla ubuhlakani bokwenziwa nezinzwa ezithuthukile, anika amandla ukuqapha kwesikhathi sangempela nokulungiswa okuzenzakalelayo. Lezi zici ziqinisekisa ikhwalithi engaguquki futhi zinciphisa udoti wezinto ezibonakalayo. Isibonelo, ukuqapha okuqhubekayo kuthuthukisa ukulandelelwa kwedatha, okuvumela abakhiqizi ukuthi bakhombe futhi baxazulule izinkinga ngokushesha.

Amasistimu azenzakalelayo nawo akhulisa isivinini sokukhiqiza nokuhamba komsebenzi. Imishini efakwe amarobhothi ingakwazi ukuzivumelanisa nezinhlobo zamabhodlela ahlukahlukene, iqede isidingo sokusetha okuningi. Lokhu kuvumelana nezimo kunciphisa isikhathi sokuphumula futhi kukhulisa okukhiphayo. Ukwengeza, ukuxhumana okusebenziseka kalula kwenza imisebenzi ibe lula, yehlise izimfuneko zokuqeqeshwa futhi ithuthukise ukukhiqiza okuphelele.

| Isici | Incazelo |

|---|---|

| Ukunemba nokuvumelana | I-automation iqinisekisa ukuthi ibhodlela ngalinye lihlangabezana nokucaciswa okuqondile, ukunciphisa amaphutha kanye nemfucuza. |

| Isivinini | Amasistimu azenzakalelayo athuthukisa kakhulu isivinini sokukhiqiza futhi anciphise ukubambezeleka. |

| I-Smart Manufacturing | Ukuhlanganiswa nezinhlelo zedatha kuvumela ukulungiswa okubikezelwayo kanye nokwenza kahle kokusebenza. |

Lezi ntuthuko zenza okuzenzakalelayo kube isici esibalulekile kubakhiqizi abahlose ukuhlala bencintisana emakethe esheshayo.

Ukuhlukahluka Kumiklamo Yebhodlela Nosayizi

Imishini yesimanje yokufutha amabhodlela inikeza ukuguquguquka okumangalisayo, okuhlanganisa aububanzi bemiklamo yamabhodlelanamasayizi. Imishini efana nochungechunge lwe-JT iyahamba phambili ekukhiqizeni amabhodlela anomumo nevolumu ehlukahlukene, kusukela ezitsheni ezincane ezingu-100 ml kuya emikhiqizweni emikhulu engama-50-litre. Amasistimu okulawula athuthukile nezinzwa ziqinisekisa ukunemba, ukugcina ubuqotho besakhiwo kuyo yonke imiklamo.

Abakhiqizi bayazuza kulokhu kuvumelana nezimo, njengoba kuqeda isidingo semishini eminingi yokusingatha izinhlobo zamabhodlela ezahlukene. Isibonelo, imishini yokubumba i-PET Technologies 'ingakwazi ukukhiqiza amabhodlela ezinhlelo zokusebenza ezibuyiswayo kuyilapho isekela izinto ze-PET ezigaywe kabusha ezingu-100%. Leli khono lihambisana nezitayela zomkhakha eziya ezixazululweni zokupakisha ezingasindi nezisimeme.

- Imishini ingaphatha ubujamo bebhodlela nosayizi abahlukahlukene, iqinisekisa ukunemba okuphezulu nokusebenza kahle.

- Izinzwa ezithuthukile zilungiselela izimo zokukhiqiza, zithuthukisa ukuguquguquka ekukhiqizeni.

Lokhu kuguquguquka kuvumela abakhiqizi ukuthi bahlangabezane nezidingo zezimboni ezahlukahlukene, kusukela eziphuzweni kuye kwezokwelapha, kalula.

Ukuhlanganiswa Nemikhuba Eqhubekayo

Ukusimama sekuyinto ebalulekile ekugxilweni kwayo ekukhiqizeni amabhodlela. Imishini ethuthukisiwe yokufutha amabhodlela manje isihlanganisa amasistimu awonga amandla futhi isekela ukusetshenziswa kwezinto ezigaywe kabusha. Ama-motor frequency motors kanye nama-hydraulics alawulwa yi-servo anciphisa ukusetshenziswa kwamandla ngamaphesenti angama-30, ehlisa izindleko zokusebenza kanye nomthelela wemvelo.

Izibonelo zezifundo zigqamisa impumelelo yalezi zinhlelo. Inkampani yesiphuzo yaseNyakatho Melika izuze ukuncipha ngo-30% kokusetshenziswa kwamandla kanye nokwenyuka kwejubane lokukhiqiza ngo-20% ngokuthatha izinqubo ezizinzile. Ngokufanayo, umkhiqizi womkhiqizo wokunakekelwa komuntu waseYurophu wehlise kakhulu imfucuza ngenkathi ethuthukisa ukwaneliseka kwamakhasimende.

| Igama Lenkampani | Ukunciphisa Amandla | Isivinini Sokukhiqiza | Ukuncishiswa Kwemfucuza | Ukwaneliseka Kwekhasimende |

|---|---|---|---|---|

| I-North American Beverage Company | 30% | 20% | N/A | N/A |

| Umkhiqizi Womkhiqizo Wokunakekela Umuntu WaseYurophu | 25% | N/A | Okubalulekile | Kuthuthukisiwe |

Ngokuhlanganisa izinqubo ezizinzile, abakhiqizi abagcini nje ukunciphisa izindleko kodwa futhi bahambisana nemigomo yemvelo yomhlaba wonke, bathuthukise isithunzi sabo semakethe.

Izicelo Zomhlaba Wangempela Zemishini Yokuvuthela Amabhodlela

Izimboni Zokupakisha Iziphuzo nokudla

Izimboni zokupakisha iziphuzo nokudla zithembele kakhulu kukhoimishini yokufutha amabhodlelaukuhlangabezana nesidingo esikhulayo sezisombululo zokupakisha ezisebenza kahle nezisezingeni eliphezulu. Le mishini ikhiqiza amabhodlela emikhiqizo enhlobonhlobo, okuhlanganisa amanzi, amajusi, iziphuzo ezibandayo, amasoso namafutha adliwayo. Ukusetshenziswa kwamanzi asemabhodleleni emhlabeni wonke kukhuphuka ngo-7.0% ngonyaka, nokuqagela okukhombisa ukunyuka kusuka kumalitha ayizigidi eziyizinkulungwane ezingama-232 ngo-2011 kuya kumalitha ayizigidi eziyizinkulungwane ezingama-513 ngo-2025. Lokhu kukhula kugqamisa isidingo sobuchwepheshe bokupakisha obusezingeni eliphezulu obungakwazi ukuhambisana nezidingo zemakethe.

Izinzuzo ezibalulekile zalezi zimboni zihlanganisa isivinini sokukhiqiza esisheshayo, udoti oncishisiwe wezinto ezibonakalayo, kanye nekhono lokudala amabhodlela angasindi kodwa aqinile. Isidingo sezixazululo ezisebenzayo zokupakisha siyaqhubeka nokukhula njengoba abakhiqizi belwela ukuhlangabezana nokulindelwe ngabathengi ukuze kube nokusimama nokuba lula.

Imikhakha Yezokwelapha Nezimonyo

Imishini yokufutha amabhodlela idlala indima ebalulekile emikhakheni yezemithi nezimonyo, lapho ukunemba nekhwalithi kubaluleke kakhulu. Embonini yezemithi, le mishini ikhiqiza amabhodlela aklanyelwe ukugcina nokuthutha ngokuphepha ama-syrups, amaphilisi, amaphilisi, kanye nemithi ewuketshezi. Okwezimonyo, bakha iziqukathi ezikhangayo zokugcoba, okhilimu, ama-shampoos, neziqholo, ezithuthukisa ukwethulwa komkhiqizo nokuthengiseka.

| Umkhakha | Incazelo Yohlelo Lokusebenza |

|---|---|

| Ezemithi | Ukukhiqiza amabhodlela okupakisha ekhemisi ukuqinisekisa ukugcinwa okuphephile kanye nokuthuthwa kwemithi. |

| Izimonyo | Ukudala amabhodlela e-cosmetic amahle ukuze kuthuthukiswe izinga nokukhanga kwemikhiqizo emakethe. |

Ukuguquguquka kwemishini yokufutha amabhodlela kuvumela abakhiqizi ukuthi bazivumelanise nezidingo eziyingqayizivele zalezi zimboni, baqinisekise ukuhambisana nezindinganiso eziqinile zokulawula ngenkathi begcina ukukhanga kobuhle.

Izibonelo Zezinkampani Ezisebenzisa Imishini Ethuthukisiwe

Izinkampani eziningi zithole ngempumelelo imishini yokufutha amabhodlela ethuthukisiwe ukuthuthukisa amakhono azo okukhiqiza. I-Beermaster, inkampani yesiphuzo eMoldova, yasebenzisa umshini wokubumba uchungechunge lwe-APF-Max ukufeza intuthuko enkulu. Umshini ukhuphule umkhiqizo wokukhiqiza waba amabhodlela ayi-8,000 ngehora ngamabhodlela angama-500 ml, wadlula amakhono angaphambilini. Izinguquko zesikhunta ezisheshayo, eziqedwe emizuzwini engama-20 nje kuphela, zinikeze ukuguquguquka kokukhiqiza osayizi bebhodlela abahlukene abahlanu. Ukwengeza, ukuthuthukiswa kokusebenza kahle kwamandla okuhambisana nezinqubo ezizinzile, kunciphisa ukusetshenziswa kwamandla okuphelele. Izinketho zokwenza ngendlela oyifisayo imiklamo yamabhodlela yaqinisa futhi ukuqashelwa komkhiqizo kanye nokukhanga okubonakalayo.

Lezi zibonelo zikhombisa ukuthi imishini ethuthukisiwe yokufutha amabhodlela inika amandla kanjani amabhizinisi ukuthi aqhubeke nokuncintisana ngokuthuthukisa ukusebenza kahle, ukunciphisa izindleko, nokuhlangabezana nezidingo zemakethe ezahlukahlukene.

Imishini ethuthukisiwe yokufutha amabhodlela, njengochungechunge lwe-JT, ichaza kabusha ukukhiqiza ngokukhuphula isivinini sokukhiqiza, ukuqinisekisa ikhwalithi engaguquki, nokunciphisa ukusetshenziswa kwamandla. Imiklamo yabo ehlangene, eyi-modular yenza lula imijikelezo yokukhiqiza, kuyilapho izinto eziqinile zithuthukisa ukwethembeka. Amasistimu awonga amandla ehlisa izindleko kanye nomthelela emvelweni, okwenza le mishini ibaluleke kakhulu ezinkampanini ezilwela ukuhlala zincintisana ezimakethe eziguqukayo.

| Isici | Incazelo |

|---|---|

| Isivinini Sokukhiqiza | Imiklamo ehlangene, eyi-modular ihlanganisa ngaphandle komthungo emigqeni yokukhiqiza, isheshisa imijikelezo. |

| Ikhwalithi | Izinto ezihlala isikhathi eside kanye namasu athuthukile kuqinisekisa ukukhishwa okuthembekile, okuphezulu. |

| Ukusebenza Kwamandla | Imiklamo yokonga amandla inciphisa izindleko zokusebenza futhi isekela izinqubo zokukhiqiza ezizinzile. |

FAQ

Yiziphi izinto ezingenziwa inqubo yomshini wokufutha ibhodlela le-JT?

Uchungechunge lwe-JT lubambaizinto ezifana PE, PP, kanye no-K, okwenza kube nezinto ezihlukahlukene ekukhiqizeni imikhiqizo yepulasitiki engenalutho kuzo zonke izimboni ezihlukahlukene.

Uchungechunge lwe-JT luqinisekisa kanjani ukusebenza kahle kwamandla?

Umshini usebenzisa amamotho ashintshashintshayo nama-hydraulics alawulwa yi-servo, wehlisa ukusetshenziswa kwamandla ngo-15% kuya ku-30% uma kuqhathaniswa namamodeli wendabuko.

Ingabe uchungechunge lwe-JT lungakwazi ukwamukela osayizi bamabhodlela abahlukene?

Yebo, umsebenzi wokuphakamisa isiteji kanye nezinhlelo zokulawula ezithuthukisiwe zivumela uchungechunge lwe-JT ukuthi lukhiqize amabhodlela asukela ku-20 kuya ku-50 amalitha ngokunemba.

Ithiphu: Ukuze uthole imiphumela emihle, lungisa izilungiselelo zomshini ngokusekelwe ezintweni ezibonakalayo kanye nezidingo zosayizi webhodlela.

Isikhathi sokuthumela: May-23-2025