Ukusebenza kahle kuqhuba impumelelo ekukhiqizeni amabhodlela. Iqinisekisa ukuthi abakhiqizi bahlangabezana nezidingo zemakethe ezikhulayo ngenkathi belawula izindleko. Isibonelo, ukukhulisa i-Production Efficiency Ratio kusuka kumayunithi angama-20 kuye kwangama-30 ngehora nokunciphisa imfucuza isuka ku-5% iye ku-10% kungakhuphula kakhulu inzuzo. Amathuluzi athuthukile njengomshini wokufutha amabhodlela wochungechunge lwe-JT asiza ukufeza lezi zinhloso. Idizayinelwe ukuguquguquka, isebenza ngaphandle komthungo ngezinto ezifana ne-PE ne-PP, kufaka phakathi izinhlelo zokusebenza ku-Imboni yomshini wokuphehla i-PVC, enikeza ukunemba okuthuthukisiwe nesivinini. Ukuthi ukhiqiza amabhodlela alungele imvelo noma uyahlolaumjovo welula igalelo ukubumba, izinqubo zokuthuthukisa ziba ezibalulekile. Ulungele ukuguqula ulayini wakho wokukhiqiza ngePP umshini wokufutha ibhodlela? Ake sicwilise!

Ukukhetha Umshini Wokuvuthela Ibhodlela Ofanele

Ukuhlola izidingo zokukhiqiza namandla

Ukukhetha umshini ovuthela ibhodlela ofanele kuqala ngokuqonda owakhoimigomo yokukhiqiza. Abakhiqizi badinga ukuhlola izici ezifana nenani lamabhodlela akhiqizwa ngehora, ubukhulu bamabhodlela, kanye nobunkimbinkimbi bemiklamo yabo. Isibonelo, amabhodlela amakhudlwana adinga imishini enamandla amakhulu okubamba, kuyilapho imiklamo eyinkimbinkimbi idinga ukuhambisana kwesikhunta okuthuthukisiwe.

Amandla okukhiqiza adlala indima ebalulekile kulokhu kuhlola. Ukwazi umthamo wokudubula womshini kusiza abakhiqizi bagweme amaphutha abizayo. Imishini engaphansi kobukhulu ngokuvamile iholela ekushintsheni kwesikhunta njalo, inciphise ukukhiqizwa. Ngakolunye uhlangothi, imishini emikhulu ingamosha izinto zokwakha futhi yandise izindleko zokusebenza. Ukuze bathole ukulingana okulungile, abakhiqizi kufanele babale umthamo we-mold cavity kanye nesisindo sokudubula ngokusekelwe kubuningi be-resin yepulasitiki.

Okunye okucatshangelwayo kufaka phakathi uhlobo lwezinto ezisetshenzisiwe, indawo etholakalayo yomshini, kanye nokusebenza kahle kwamandla. Imishini eyenza isikhala nokusetshenziswa kwamandla ayigcini nje ngokugcina izindleko kodwa futhi ithuthukisa ukukhiqiza sekukonke.

Izinzuzo zomshini wokufutha amabhodlela wochungechunge lwe-JT

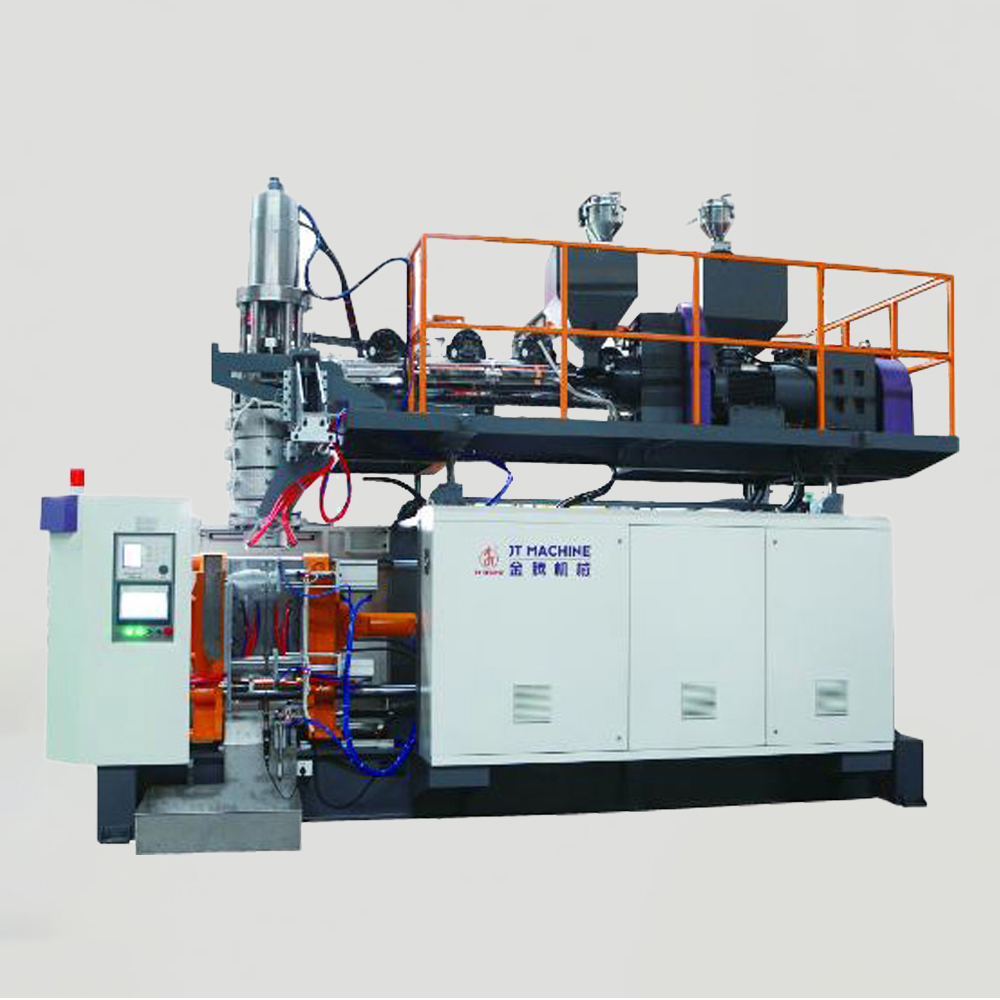

IUmshini wokufutha ibhodlela wochungechunge lwe-JTigqama njengekhambi eliguquguqukayo nelisebenza kahle labakhiqizi. Ithatha izinhlobonhlobo zamasayizi amabhodlela, kusukela ezitsheni ezincane ze-100 ml kuya emikhiqizweni emikhulu engama-50-litre, okuyenza ilungele izidingo ezihlukahlukene zokukhiqiza. Isistimu yayo yokulawula ethuthukisiwe iqinisekisa ukunemba, igcina ubuqotho besakhiwo samabhodlela kuyo yonke imiklamo ehlukahlukene.

Lo mshini uhlanganisa ubuchwepheshe obusezingeni eliphezulu njengokuvunguza kwe-servo stretch kanye namasistimu okushisa e-infrared. Lezi zici zinciphisa ukungahambi kahle, ziqinisekisa ngisho nokusatshalaliswa kokushisa, futhi zikhiqize amabhodlela anobukhulu obufanayo bodonga. Ukwengeza, uchungechunge lwe-JT luhlanganisa izindlela zokonga amandla ezinciphisa izindleko zokusebenza ngokufika ku-30%, okwenza kube ukukhetha okubiza izindleko zokukhiqiza okukhulu.

Abakhiqizi bayazuza ekuzivumelaniseni nezimo, njengoba uchungechunge lwe-JT luqeda isidingo semishini eminingi yokusingatha izinhlobo zamabhodlela ezihlukene. Idizayini yayo emisha nezilawuli ezihlakaniphile ziphinde zehlise udoti wezinto ezibonakalayo, konga izindleko ngokuhamba kwesikhathi eside kokukhiqiza.

Ukubaluleka kwezinhlelo zokonga ugesi nezizenzekelayo

Imishini yesimanje yokufutha amabhodlela ibeka phambili ukusebenza kahle kwamandla kanye ne-automation, iguqula izinqubo zokukhiqiza. Uma kuqhathaniswa namamodeli endabuko, le mishini inciphisa ukusetshenziswa kukagesi ngo-20-30%, yehlisa kakhulu izindleko zokusebenza. Uchungechunge lwe-JT, ngokwesibonelo, lusebenzisa ama-servo motors namadrayivu aguquguqukayo ukuze kuthuthukiswe ukusetshenziswa kwamandla.

I-automation ithuthukisa isivinini sokukhiqiza futhi inciphisa ukumosha. Izilawuli ezihlakaniphile zigcina ukubekezelelana okuqinile, ziqinisekisa ikhwalithi yamabhodlela engashintshi futhi zinciphisa amaphutha. Imiklamo engasindi nezinto ezithuthukisiwe ziphinde zibe neqhaza ekuzinzeni, okwenza le mishini ibe ukukhetha okuvumelana nemvelo.

Ngokutshala imali ezinhlelweni ezonga amandla nezizenzekelayo, abakhiqizi bangafinyelela amanani okukhiqiza asheshayo, izindleko eziphansi, kanye nekhwalithi yamabhodlela ethuthukisiwe. Lezi zinhlelo azigcini nje ngokuhlangabezana nezidingo zemakethe kodwa futhi zihambisana nokugcizelela okukhulayo kwezinqubo ezisimeme zokukhiqiza.

Ukuthuthukisa Idizayini Yesikhunta ukuze Isebenze Kahle

Izinto zokubumba ezingasindi futhi ezihlala isikhathi eside

Ukusebenzisaizinto ezingasindi futhi ezihlala isikhathi esidengoba isikhunta singathuthukisa kakhulu ukusebenza kahle kokukhiqiza. Izibunjwa zanamuhla, ezivame ukudalwa ngokukhiqiza izithasiselo zensimbi, zinciphisa amandla okushisa futhi zikhulise ukusatshalaliswa kwesitimu. Lokhu kuholela ezikhathini zomjikelezo omfushane kanye nokusetshenziswa kwamandla okuphansi.

- Isikhunta esingasindi sivumela ukushisa nokupholisa ngokushesha, okusheshisa inqubo yokukhiqiza.

- Ukuhlola kokuhlola kubonise ukuthi lezi zikhunta zidlula imiklamo evamile, izikhathi zomjikelezo wokusika kanye nokusetshenziswa kwamandla.

- Umumo oyinkimbinkimbi nawo ungafinyelelwa ngemiklamo yesikhunta emisha, kuthuthukiswe ukusebenza kahle kokukhiqiza.

Ngokwamukela lezi zinto ezithuthukisiwe, abakhiqizi bangonga isikhathi nezinsiza ngenkathi begcina ukuphuma kwekhwalithi ephezulu.

Ukwenza ngokwezifiso isikhunta semiklamo ehlukahlukene yamabhodlela

Izibunjwa zangokwezifiso eziklanyelwe imiklamo ethile yamabhodlela ziqinisekisa ukuguquguquka nokusebenza kahle. Abakhiqizi bangakwazi ukulungisa kalula isikhunta ukuze kuhambisane nosayizi abahlukahlukene kanye nokwakheka, ukwenza lula ukusebenza kanye nokunciphisa isikhathi sokuphumula.

| Iphuzu lobufakazi | Incazelo |

|---|---|

| Izinketho Zokuklama Ezivumelanayo | Ukulungiswa komumo webhodlela abahlukene kuthuthukisa ukusebenza kahle kokukhiqiza. |

| Imisebenzi Elula | Isikhunta esiklanyelwe sinciphisa isikhathi sokuphumula, sikhulise ukukhiqiza. |

| Ukuhlanganiswa Kwezobuchwepheshe | Amasistimu azenzakalelayo anciphisa umsebenzi wezandla kanye nokumosha, athuthukise umphumela wawo wonke. |

| Ikhwalithi yokulawula | Ukuqapha ngesikhathi sangempela kuqinisekisa ukukhiqizwa okungaguquki, okuphezulu. |

Isikhunta ngokwezifiso siphinde sivumele ukuhlanganiswa kobuchwepheshe obuthuthukisiwe, njengezinhlelo ezizenzakalelayo zokulawula ikhwalithi, ezithuthukisa ngokwengeziwe ukusebenza kahle futhi zinciphise imfucuza.

Ubuchwepheshe besikhunta obuthuthukisiwe bokunciphisa izikhathi zomjikelezo

Ubuchwepheshe besikhunta obuthuthukisiwe bushintsha umdlalo wokukhiqiza amabhodlela. Amasistimu okuqapha kwesikhathi sangempela ahlinzeka ngempendulo esheshayo, evumela ukulungiswa okusheshayo lapho izikhathi zomjikelezo zichezuka. Izaziso zokwenyuka ngo-10% esikhathini somjikelezo ziqinisekisa ukuthi ukusebenza kahle kuhlala kusendleleni.

Lobu buchwepheshe bonga isikhathi emisebenzini eyenziwa mathupha. Isibonelo, o-opharetha bonga imizuzu emi-5 ngokususa imibiko yephepha, kuyilapho abaphathi bezuza amaminithi angu-20 nsuku zonke ngokugwema ukufakwa kwedatha mathupha. Izibalo ziphinde zihlonze o-opharetha abangcono kakhulu besikhunta esithile, sithuthukise ukusebenza sekukonke.

Ngokusebenzisa lezi zindlela ezintsha, abakhiqizi bangafinyelela imijikelezo yokukhiqiza esheshayo nokusebenza kahle okuphezulu.

Ukuphatha Ukulawula Ukushisa Emishinini Yokuvuthela Amabhodlela

Ukushisa okungaguquki kwama-preforms

UkugcinaUkushisa okungaguquki kwama-preformskubalulekile ekukhiqizeni amabhodlela ekhwalithi ephezulu. Ukushisa okungalingani ngokuvamile kuholela ekubunjweni okungajwayelekile kanye nokushuba kodonga okungahambisani, okungafaka engozini umkhiqizo wokugcina. Ukuze ugweme lezi zinkinga, abakhiqizi kufanele baqinisekise ukuthi izakhi zokushisa zihlanzekile futhi zibekwe ngendlela efanele ukuvimbela izindawo ezishisayo. Ukusebenzisa amathuluzi afana namathemometha e-infrared kusiza ukuqapha nokugcina ukusabalalisa ukushisa okulinganayo.

Imishini yesimanje, njenge-CPSB-LSS8, ithatha lesi sinyathelo ngokuqhubekayo. Basebenzisa izitholi zokushisa ezinamaphoyinti amaningi ukuze baqinisekise ukushisa okufanayo kuwo wonke ama-preforms. Lawa masistimu asebenzisa imodeli efana nenethiwekhi ye-neural ukuze ilungise ngokuzenzakalelayo amandla okushisa, igcine amazinga okushisa engashintshi. Ukwengeza, ukutholwa kwengcindezi yesikhathi sangempela kuqinisekisa ikhwalithi yokuphefumula efanayo, okuholela kumabhodlela azinzile nathembekile.

Amanye amasistimu athuthukisiwe, afana nalawo asuka ku-TECH-LONG, alawula ngokunembile amapharamitha okushisa angaphambili kanye nokuvunguza. Lokhu kuqinisekisa ukuthi ibhodlela ngalinye lihlangabezana nezicaciso ezidingekayo, ukunciphisa amaphutha nokuthuthukisa ukungaguquguquki kokukhiqiza.

Amasistimu okupholisa athuthukile okukhiqiza okusheshayo

Izinhlelo zokupholisa ezisebenzayo zidlala indima ebalulekile ekusheshiseni ukukhiqizwa kwamabhodlela. Ngokupholisa ngokushesha ama-preforms ashisayo, lezi zinhlelo zifinyeza izikhathi zomjikelezo futhi zithuthukise ukukhiqiza. Izifundo zokusebenza zigqamisa umthelela wobuchwepheshe bokupholisa obuthuthukile:

| Imethrikhi | Umphumela |

|---|---|

| Umjikelezo wokuklama-kuya-ukukhiqiza | Yehliselwe ngaphansi kwezinyanga ezi-2 |

| Isivinini sokuphrinta | 30% ngokushesha (20h kuya ku-14h) |

| Umjikelezo wokwelapha ukushisa | Okufushane ngo-70% (4h vs 13h) |

| Ukuthuthukiswa kokukhipha ukushisa | 6% ngaphezulu |

| Ukuncishiswa kokuhlanekezela kokuphrinta | Ukuhlanekezela okuncane kuboniwe |

Lokhu kuthuthukiswa kubonisa ukuthi amasistimu okupholisa athuthukile angagcini ngokusheshisa ukukhiqiza kodwa futhi aqinisekisa ikhwalithi yomkhiqizo engcono.

Ukuqapha nokulungisa ukuguquguquka kwezinga lokushisa

Ukuqapha nokulungisaukushintsha kwezinga lokushisakuyisihluthulelo sokugcina ukuzinza kwenqubo. Ukuqapha okuphelele kwezinga lokushisa kuqinisekisa ubuqotho bomkhiqizo nokuhambisana nezindinganiso zomkhakha. Idatha yesikhathi sangempela ivumela abakhiqizi ukuthi benze izinqumo ezinolwazi, njengokulungisa izilungiselelo ukuze babhekane nokukhuphuka kwezinga lokushisa.

| Incazelo yobufakazi | Imibono Ebalulekile |

|---|---|

| Ukuqapha okuphelele kwezinto ezilawulwa izinga lokushisa | Iqinisekisa ubuqotho bomkhiqizo kanye nokuhambisana kulo lonke uchungechunge lokuhlinzeka. |

| Idatha yokuqapha izinga lokushisa kwesikhathi sangempela | Inika amandla ukwenziwa kwezinqumo okungcono kanye nokucubungula ukulungiswa. |

| Imibandela yokuvakasha evumelekile | Yehlisa ukumosha okungadingekile ngokuvumela ukuhlolwa komkhiqizo okuguquguqukayo. |

| Ukuthobela imithetho | Iqinisekisa ukubambelela ezimweni zokushisa ezifanele ukuze kuphephe nokusebenza ngempumelelo. |

Ngokusebenzisa le mininingwane, abakhiqizi banganciphisa amaphutha, banciphise ukungcola, futhi bagcine ikhwalithi yokukhiqiza engaguquki. Ukulawula izinga lokushisa kuseyinsika yokukhiqizwa kwamabhodlela okuphumelelayo.

Ukuqinisekisa Umfutho Womoya Ozinzile kanye Nekhwalithi Yegesi

Iqhaza lomfutho womoya ongaguquki ekufaneni kwamabhodlela

Umfutho womoya ozinzileidlala indima ebalulekile ekuqinisekiseni ukufana kwamabhodlela ngesikhathi sokukhiqiza. Lapho umfutho womoya ushintshashintsha, amabhodlela angakha izindonga ezingalingani noma amabala abuthakathaka, okuholela ekulimaleni. Ukucindezela okungaguquki kuqinisekisa ukuthi ibhodlela ngalinye livuthela ngokulinganayo, ligcina ukuma kwalo nobuqotho besakhiwo. Abakhiqizi bangafinyelela lokhu ngokusebenzisa izilawuli zomfutho womoya ezithuthukisiwe eziqapha futhi zilungise amazinga okucindezela ngesikhathi sangempela.

Cabanga ngalokhu ngale ndlela: umfutho womoya usebenza njengomqophi obumba ibhodlela. Uma isandla somqophi sintengantenga, umkhiqizo wokugcina ngeke ubukeke ulungile. Ngokufanayo, ukucindezela komoya okungaguquki kuqinisekisa ukuthi ibhodlela ngalinye lihlangabezana nezindinganiso zekhwalithi, ukunciphisa imfucuza kanye nokwenza ngcono ukusebenza kahle.

Amasistimu omoya ocindezelwe wekhwalithi ephezulu ukuze athembeke

Amasistimu omoya ocindezelwe wekhwalithi ephezuluzibalulekile ekukhiqizeni amabhodlela okuthembekile. Lezi zinhlelo zinikeza umoya ohlanzekile, ongaguquki, futhi omsulwa, obaluleke kakhulu ezimbonini ezifana nokudla nesiphuzo. Umoya ongcolile ungonakalisa ukuphepha komkhiqizo, ngakho-ke ukugcinwa komoya ohlanzekile akunakuxoxisana.

- Umoya ocindezelweyo uqinisekisa inhlanzeko phakathi nezinqubo ezifana nokugcwalisa nokubeka uphawu.

- Ivamise ukubizwa ngokuthi “insiza yesine” ngenxa yokuguquguquka kwayo nokuthembeka.

- Lezi zinhlelo zisebenza ngaphandle komthungo ngamathuluzi ahlukahlukene nemishini, okubenza babaluleke kakhulu ekukhiqizweni kwamabhodlela.

Ngokutshala imali ezinhlelweni zomoya ezicindezelwe ezisezingeni eliphezulu, abakhiqizi bangathuthukisa kokubili ukukhiqiza nokuphepha komkhiqizo.

Ukuhlolwa okuvamile kwezinhlelo zokuphakelwa komoya

Ukuhlolwa okuvamile kwezinhlelo zokuphakelwa komoya kuvimbela ukuwohloka okungalindelekile nokugcina ukusebenza kahle. Ngokuhamba kwesikhathi, izingxenye ezifana nezihlungi namavalvu zingaguga, okuholela ekwehleni kwengcindezi noma ukungcoliswa. Ukuhlola okuvamile kusiza ukuhlonza nokulungisa lezi zinkinga ngaphambi kokuba zidlulele.

Uhlelo olulula lokulungisa lungenza umehluko omkhulu. Isibonelo, ukuhlola izihlungi nyanga zonke nokuzishintsha njengoba kudingeka kugcina isistimu isebenza kahle. Ngokuhlala bekhuthele, abakhiqizi bangagwema isikhathi sokuphumula esibizayo futhi baqinisekise ikhwalithi yomoya engaguquki kuyo yonke inqubo yokukhiqiza.

Ithiphu: Gcina ilogi yemisebenzi yokuhlola kanye neyokulungisa. Lokhu kusiza ukulandelela ukusebenza futhi kuqinisekisa ukuthi akukho mininingwane enganakwa.

Ukuthuthukisa Amakhono Okusebenza Ngokusebenza Kangcono

Ukuqeqesha ama-opharetha kumasistimu athuthukile njengochungechunge lwe-JT

Ama-opharetha adlala indima ebalulekile ekwandiseni amandla emishini ethuthukisiwe, njengomshini wokuvuthela amabhodlela wochungechunge lwe-JT. Ukuqeqeshwa okufanele kuqinisekisa ukuthi bayaqonda izici zomshini, njengesikrini sokuthinta se-Siemens IE V3 1000 esisebenzayo kanye nesistimu esebenza ngogesi eyonga amandla. Izikhathi zokuqeqesha ezisebenza ngezandla zivumela opharetha ukuthi bazijwayeze nalezi zinhlelo, behlise amaphutha futhi bathuthukise isivinini sokukhiqiza.

Ucwaningo lwezinhlelo zokuqeqesha lwembula izinzuzo ezibalulekile. Ngokwesibonelo:

| Incazelo yobufakazi | Umthelela Ekusebenzeni | Ukubuyiselwa Kwezimali |

|---|---|---|

| Ukuqeqeshwa kuholele ekwehleni ngo-11-68% kumazinga e-BOD/TSS | Ukuthuthukiswa okubonakalayo kumamethrikhi okusebenza kwezitshalo | $91 imbuyiselo yedola ngalinye elitshalwe ekuqeqesheni |

| Ukuqeqeshwa kwathuthukisa amakhono kanye nokusebenza kahle kwezitshalo | Intuthuko isiyonke isukela ku-112% yaya ku-334% ngaphezu kwamazinga angaphambi kokuqeqeshwa | Ukutshalwa kwezimali okuphezulu esitshalweni ngomqhubi ngamunye, ngaphezu kwama-$64,000 |

| Izibonelo zezifundo zibonise umthelela onamandla onenzuzo wokuqeqeshwa | Ukusebenza okuthuthukisiwe ezitshalweni ezisezingeni eliphansi ngokomlando | N/A |

Le miphumela igqamisa ukubaluleka kokutshala imali ekuqeqesheni umsebenzi ukuze uvule amandla aphelele emishini yesimanje.

Ukukhuthaza ukufunda okuqhubekayo nokuthuthukiswa kwamakhono

Ukukhuthaza abaqhubi ukuthi bamukele ukufunda okuqhubekayo kukhuthaza isiko lokuqamba izinto ezintsha nokuzivumelanisa nezimo. Ama-workshops avamile nezifundo zokuvuselela zigcina zinolwazi lwakamuva mayelana namathrendi nobuchwepheshe bomkhakha wakamuva. Isibonelo, ukufunda ngemiklamo yesikhunta ethuthukisiwe noma amasistimu okulawula izinga lokushisa kungasiza opharetha ukuhlonza amathuba okuthuthukisa ukusebenza kahle.

Abaphathi bangasebenzisa nezinhlelo zokufundisa lapho opharetha abanolwazi beqondisa amalungu eqembu amasha. Le ndlela yokufundisa ayigcini nje ngokwakha ukuzethemba kodwa futhi iqinisekisa ukudluliswa kolwazi kubo bonke abasebenzi. Ngokubeka phambili ukuthuthukiswa kwamakhono, abakhiqizi bangakha iqembu elihlala liletha imiphumela yekhwalithi ephezulu.

Inika amandla opharetha ukuthi baxazulule futhi balungiselele izinqubo

Ukunika amandla ama-opharetha ekuxazululeni izinkinga nokwenza kahle izinqubo zokukhiqiza kunciphisa isikhathi sokuphumula futhi kuthuthukisa ukusebenza kahle. Uma opharetha bekwazi ukuhlonza futhi baxazulule izinkinga ngokuzimela, imigqa yokukhiqiza isebenza kahle kakhulu. Ukuhlelwa okusebenzayo kokulungisa kanye namathuluzi okuqapha ngesikhathi sangempela, njengamadeshibhodi amaphakathi, anika amandla opharetha ukuthi abhekane nezinkinga ngaphambi kokuba zikhule.

- Ukunakekela okubikezelwayo kubikezela ukwehluleka kwemishini, okuvumela ukuhlela okumatasa.

- Ukuhlolwa kwemishini okuvamile kusiza ekutholeni ukuguga nokuguga kusenesikhathi, kuvimbele ukuwohloka okungalindelekile.

- Amadeshibhodi abiwe anikeza umbono ocacile wamamethrikhi okusebenza, asiza ukuthathwa kwezinqumo ngokushesha.

Ngokuhlomisa opharetha ngamathuluzi nolwazi olufanele, abakhiqizi banganciphisa ukuphazamiseka futhi bagcine okukhiphayo okungaguquki.

Ukugcinwa Okuvamile Nokunakekelwa Kwemishini Yokuvuthela Amabhodlela

Amashejuli okuvikela okugcina impilo ende

Ukugcinwa kokuvimbelakuwumgogodla wokugcina umshini wokufutha ibhodlela usebenza kahle. Ngokuhlela ukuhlolwa okuvamile, abakhiqizi bangakwazi ukubamba izinkinga ezingaba khona ngaphambi kokuba zidlulele ekuwohlokeni okumba eqolo. Kucabange njengokuthatha imoto yakho iyoshintsha uwoyela—kuwumzamo omncane okusindisayo ezinkingeni ezinkulu ezansi nomgwaqo.

Ucwaningo lubonisa ukuthi ukusebenzisa ukulungiswa kokuvimbela kuthuthukisa kakhulu ukwethembeka komshini futhi kunciphisa isikhathi sokuphumula. Ngokwesibonelo:

| Umshini | Ukuthembeka Ngaphambili | Ukwethembeka Ngemva | Ukuthuthukiswa (%) | Isikhathi Esimaphakathi Phakathi Kokuhluleka Ngaphambilini | Isikhathi Esimaphakathi Phakathi Kokuhluleka Ngemva | Khulisa (%) |

|---|---|---|---|---|---|---|

| Isiqephu 26 | 0.45963 | 0.55756 | 21% | 6.87898 | 9.77866 | 42% |

| Isiqephu 21 | 0.4856 | 0.5430 | 12% | N/A | N/A | 46% |

Lezi zinombolo zigqamisa ukuthi uhlelo lokulungisa olulula lungenza kanjani umehluko omkhulu. Ukuma kokukhiqiza okuncane, okungenzeka izikhathi ezifika ku-20,000 ngonyaka, kungase kubonakale kungabalulekile ekuqaleni. Nokho, bangeza ngokushesha, kube nomthelela kokubili ukukhiqiza kanye nenzuzo. Indlela ehlelekile, efana ne-Reliability-Centered Maintenance (RCM), ilindele ukuguga, nokuqinisekisa ukuthi imishini ihlala isesimweni esiphezulu.

Ithiphu: Dala ikhalenda yokulungisa futhi unamathele kuyo. Ukuhlola okuvamile nokushuna kuzogcina umugqa wakho wokukhiqiza uduma ngaphandle kweziphazamiso.

Amasistimu okugcoba okuzenzakalelayo ochungechungeni lwe-JT

Umshini wokufutha amabhodlela wochungechunge lwe-JT uthatha ukunakekelwa kuyise ezingeni elilandelayo ngohlelo lwawo lokuthambisa oluzenzakalelayo. Lesi sici siqinisekisa ukuthi zonke izingxenye ezihambayo zithola inani elifanele lokugcotshwa ngesikhathi esifanele, kunciphisa ukuguga. Ama-opharetha akusadingeki ukuthi agcobe mathupha izingxenye, okonga isikhathi futhi kunciphisa iphutha lomuntu.

Ukugcotshwa okuzenzakalelayo futhi kwandisa isikhathi sokuphila sezingxenye ezibalulekile, njengesistimu ye-hydraulic kanye nemihlahlandlela eqondile. Ngokugcina lezi zingxenye zisesimweni esifanele, umshini usebenza ngokuphumelelayo nangesikhathi esincane sokuphumula. Lolu hlelo luzuzisa kakhuluimigqa yokukhiqiza enevolumu ephezulu, lapho ngisho nokubambezeleka okufushane kungase kuphazamise amashejuli.

Qaphela: Isistimu yokugcoba yochungechunge lwe-JT ayigcini nje ngokuthuthukisa ukusebenza kodwa futhi inciphisa umthwalo wokulungisa, ikhulula opharetha ukuthi bagxile kweminye imisebenzi.

Ukuhlola nokushintsha izingxenye ezigugile

Ngisho nangezindlela zokunakekela ezingcono kakhulu, ezinye izingxenye zizogcina sezigugile. Ukuhlola okuvamile kusiza ukukhomba lezi zingxenye ngaphambi kokuthi zihluleke. Isibonelo, izihlungi, ama-valve, nezikulufi kuyizindawo zokugqoka ezivamile emishinini yokufutha amabhodlela. Ukuwashintsha ngokushesha kuqinisekisa ukuthi umshini uyaqhubeka nokusebenza kahle kakhulu.

Indlela esebenzayo yokuhlola ingavimbela ukwephuka okungalindelekile. Ama-opharetha kufanele ahlole izimpawu zokuguga, njengemisindo engajwayelekile, izikhathi zomjikelezo ongasheshi, noma ikhwalithi yebhodlela engahambisani. Ukugcina ilogi yalokhu kuhlola kusiza ukulandelela isimo sengxenye ngayinye, okwenza kube lula ukuhlela ukushintshwa.

I-callout: Ungalindi ukuthi ingxenye ethile ingaphumeleli ngokuphelele. Ukushintsha izinto ezigugile kusenesikhathi konga imali futhi kugwema isikhathi sokuphumula esibizayo.

Ngokuhlanganisa ukulungiswa kokuvimbela, ukugcotshwa okuzenzakalelayo, nokuhlolwa okuvamile, abakhiqizi bangakwazi ukukhulisa ukusebenza kahle nempilo yemishini yabo yokufutha amabhodlela. Lezi zinqubo azigcini nje ukunciphisa izindleko kodwa futhi ziqinisekisa ukukhiqizwa okungaguquki, okusezingeni eliphezulu.

Ukulungisa Isivinini Sokukhiqiza kanye Nezinhlaka Zenqubo

Ukulinganisa isivinini kanye nekhwalithi ukuze unciphise amaphutha

Ukuthola ibhalansi efanele phakathi kwejubane lokukhiqiza nekhwalithi kubalulekile ekwehliseni amaphutha. Ukusheshisa inqubo kuvame ukuholela emaphutheni, kuyilapho isivinini esiqapha ngokweqile singanciphisa okukhiphayo. Abakhiqizi bangafinyelela le bhalansi ngokuhlanganisaizinhlelo zokuqapha eziphambiliezibona izinkinga kusenesikhathi. Isibonelo, izinzwa zingakwazi ukubona okungahambi kahle kugqinsi noma umumo webhodlela, okuvumela opharetha ukuthi benze ukulungisa okusheshayo.

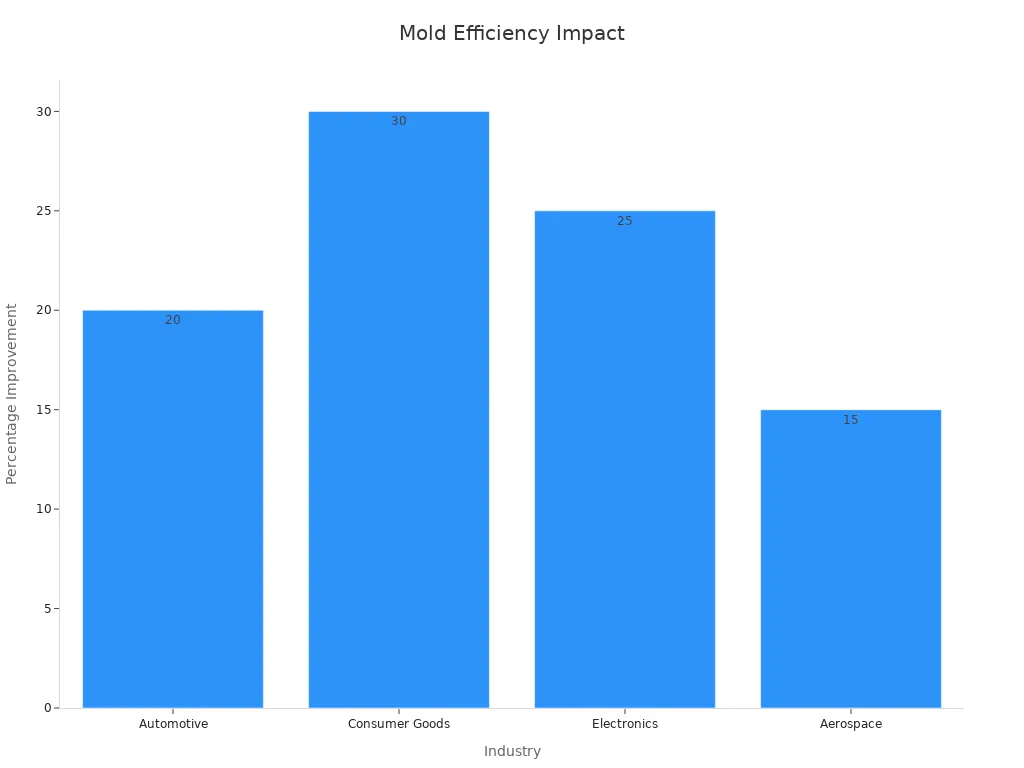

Ucwaningo lwezimboni ezihlukahlukene lugqamisa izinzuzo zokulinganisa isivinini nekhwalithi:

| Ucwaningo lwesigameko | Okutholakele |

|---|---|

| I-Electronics Assembly Plant | Idatha yenzwa ithuthukise ukusebenza kahle futhi yehlise namazinga amaphutha. |

| Umkhiqizi Wezingxenye Zezimoto | Izinhlelo zokuqeqesha abasebenzi zehlisa izinga lokukhubazeka, okufakazela ukubaluleka kwemfundo. |

| Ukuhlaziywa Kwenqubo Yokubumba | Ukulawula izinga lokushisa okungcono kwehlise amaphutha, kuqinisekisa ikhwalithi engaguquki. |

Lezi zibonelo zibonisa ukuthi ukuhlanganisa ubuchwepheshe nokuqeqeshwa kungathuthukisa kanjani kokubili isivinini nekhwalithi, kunciphise ukumosha nokuthuthukisa ukusebenza kahle.

Izilungiselelo zokulungisa kahle ukuze usebenze kahle

Ukulungiswa okuncane kuzilungiselelo zomshini kungenza umehluko omkhulu ekusebenzeni kahle kokukhiqiza. Abasebenzisi kufanele babuyekeze amapharamitha afana nomfutho womoya, izinga lokushisa, nezikhathi zomjikelezo ukuze baqinisekise ukuthi ahambisana nemigomo yokukhiqiza. Imishini efana nochungechunge lwe-JT yenza le nqubo ibe lula ngezilawuli ezinembile kanye nempendulo yesikhathi sangempela.

Ngokwesibonelo,ukulungisa amandla e-clampingamabhodlela amakhudlwana noma ukulungisa iphrofayili yokushisa yezinto ezihlukene kungavimbela amaphutha. Ukuhlola njalo lezi zilungiselelo kuqinisekisa ukuthi umshini usebenza ngokusezingeni eliphezulu, ulethe imiphumela engaguquki.

Ithiphu: Gcina ilogi yezilungiselelo eziphumelelayo zemiklamo ehlukene yamabhodlela. Lokhu kusiza opharetha ukuthi baphindaphinde izimo ezifanele ngokushesha.

Ukusebenzisa izibalo zedatha zokulungiswa kwesikhathi sangempela

Ukuhlaziywa kwedatha kuguqula indlela abakhiqizi abalungiselela ngayo ukukhiqiza. Imininingwane yesikhathi sangempela ivumela opharetha ukuthi babone ukungasebenzi futhi benze izinguquko ngokushesha. Ngokwesibonelo:

- Lungisa ukugeleza komsebenzi ukuze ubhekane nezingqinamba.

- Thuthukisa ikhwalithi yomkhiqizo ngokuhlonza amaphutha kusenesikhathi.

- Thuthukisa ukuphathwa kwe-supply chain ngokuhlela okungcono.

Indlela yesinyathelo ngesinyathelo yokusebenzisa ama-analytics ingathuthukisa ukusebenza:

| Isinyathelo | Incazelo |

|---|---|

| 1 | Khomba imishini evame ukuphazamisa ukukhiqizwa. |

| 2 | Hlaziya amaphethini okuhluleka, njengezinjini ezishisa kakhulu. |

| 3 | Yakha amamodeli aqagelayo usebenzisa idatha yenzwa efana nezinga lokushisa nokudlidliza. |

| 4 | Hlela ukulungiswa ukuze unciphise isikhathi sokuphumula. |

Ngokusebenzisa la mathuluzi, abakhiqizi banganciphisa isikhathi somshini, bathuthukise ukusebenza kahle, futhi bagcine amazinga aphezulu. Izinqumo eziqhutshwa yidatha ziqinisekisa ukuthi imigqa yokukhiqiza ihlala ishesha futhi isabela ezinseleleni.

Ukusebenzisa Amasistimu Okulawula Ikhwalithi

Ukuhlolwa okuvamile ngesikhathi sokukhiqiza

Ukuhlola okuvamile kugcina imigqa yokukhiqiza isebenza kahle. Ngokubheka amabhodlela ngesikhathi sokukhiqiza, abakhiqizi bangakwazi ukubamba amaphutha kusenesikhathi. Lokhu kuvimbela imfucuza futhi kuqinisekisa ikhwalithi engaguquki. Ama-opharetha kufanele aqaphe izinto ezibalulekile njengokuqina kodonga, umumo, nokusatshalaliswa kwezinto. Amathuluzi alula, njengama-caliper noma amageji, angasiza ngalawa masheke.

Amasistimu okuqapha ngesikhathi sangempela athatha lesi sinyathelo esiqhubekayo. Izinzwa ezithuthukile zilandelela amapharamitha okukhiqiza ngokuqhubekayo, zinikeza impendulo esheshayo. Isibonelo, uma ubukhulu bebhodlela buwela ngaphandle kwebanga elamukelekayo, isistimu yazisa opharetha ngokushesha. Lokhu kuvumela ukulungiswa okusheshayo, ukunciphisa isikhathi sokuphumula kanye nokwenza ngcono ukusebenza kahle.

Ithiphu: Hlela ukuhlolwa ngezikhathi ezithile ukuze ugweme izinkinga ezingaba khona.

Amathuluzi okulawula ikhwalithi azenzakalelayo ngokunemba

I-automation iguqule ukulawulwa kwekhwalithi. Amathuluzi afana nombono wekhompyutha namasistimu anikwe amandla yi-AI ahlonza amaphutha ngokunemba okumangalisayo. Lobu buchwepheshe budlula ukuhlolwa komuntu ngokuthola ngisho nokungahambi kahle okuncane.

Isibonelo, izinhlelo zokuhlola ezizenzakalelayo zingaskena amakhulu amabhodlela ngomzuzu. Babona amaphutha njengezindawo ezingalingani noma izindawo ezibuthakathaka ezingase zingabonakali ngenye indlela. Lokhu kuqinisekisa ukuthi wonke amabhodlela ahlangabezana nezindinganiso eziphakeme ngaphambi kokushiya umugqa wokukhiqiza.

| Uhlelo Lokulawula Ikhwalithi | Incazelo |

|---|---|

| Ukuqapha kwesikhathi sangempela | Izinzwa ezithuthukile namadivayisi e-IoT alandelela amapharamitha wokukhiqiza ngokuqhubekayo |

| Amasistimu okuhlola azenzakalelayo | Umbono wekhompyutha kanye nobuchwepheshe obunamandla e-AI bukhomba amaphutha ngokunemba okukhulu kunokuhlola komuntu |

| Ukukhiqiza okuthambile | Igxile ekuqedeni udoti kanye nokwenza ngcono ukusebenza kahle ngenkathi igcina ikhwalithi |

| Indlela ye-Sigma eyisithupha | Yehlisa ukuhluka kwenqubo ukuze kuzuzwe amazinga ekhwalithi acishe aphelele |

Ngokwamukela la mathuluzi, abakhiqizi bangathuthukisa ukunemba futhi banciphise ukumosha.

Ukubhekana nezinkinga ngokushesha ukuze kuncishiswe imfucuza

Isenzo esisheshayo siyisihluthulelo uma kwenzeka iphutha. Ukungazinaki izinto ezincane kungaholela ezinkingeni ezinkulu, ukwandisa imfucuza kanye nokunciphisa ukukhiqizwa. Ama-opharetha kufanele abhekane nezinkinga ngokushesha nje lapho zitholwa.

Isibonelo, uma iqoqo lamabhodlela libonisa ukushuba okungalingani, opharetha bangalungisa izilungiselelo zomshini ngokushesha. Lokhu kuvimbela ukukhubazeka okwengeziwe futhi konga izinto. UkusebenzisaIndlela ye-Sigma eyisithuphaisiza ukunciphisa ukuhlukahluka kwenqubo, iqinisekisa ikhwalithi engaguquki.

I-callout: Indlela esheshayo yokugwema ukukhubazeka yonga isikhathi, imali, nezinsiza.

Ngokuhlanganisa ukuhlola okuvamile, amathuluzi azenzakalelayo, kanye nesinyathelo esisheshayo, abakhiqizi bangagcina amazinga aphezulu okukhiqiza kuyilapho benciphisa imfucuza.

Ukuthuthukisa ukusebenza kahle kokukhiqizwa kwamabhodlela kudinga inhlanganisela yamasu ahlakaniphile namathuluzi afanele. Ubuchwepheshe obuthuthukisiwe, njengomshini wokufutha amabhodlela wochungechunge lwe-JT, buqondisa izinqubo futhi bunciphise imfucuza. Ama-opharetha anamakhono, aqeqeshelwe ukuphatha amasistimu esimanje, angakwazi ukuxazulula inkinga ngokushesha futhi athuthukise ukusebenza. Ukunakekelwa okuvamile kuqinisekisa ukuthi imishini isebenza kahle, kuvimbela ukwehla kwezindleko.

- Imishini ethuthukisiwe ithuthukisa okuzenzakalelayo nokulawula.

- Ama-opharetha aqeqeshiwe athuthukisa ukusebenza kahle ngokuphendula izindaba ngempumelelo.

- Ukunakekela kunciphisa ukuphuka futhi kwandisa isikhathi sokuphumula.

Ngokwamukela lezi zinqubo, abakhiqizi bangazuza ngokushesha, ukukhiqiza okuthembekile. Qala ukusebenzisa lawa macebiso namuhla ukuze uhlale uphambili emakethe yokuncintisana!

FAQ

Yini eyenza umshini wokufutha ibhodlela lochungechunge lwe-JT uwonge amandla?

Uchungechunge lwe-JT lusebenzisa ama-servo motors nama-variable frequency drives, kunciphisa ukusetshenziswa kwamandla ngo-15-30%. Lo mklamo uqinisekisa ukonga izindleko futhi usekela izinqubo zokukhiqiza ezizinzile.

Ngabe abakhiqizi kufanele banakekele kangaki emishinini yokufutha amabhodlela?

Ukugcinwa kokuvimbela kufanele kwenzeke nyanga zonke. Ukuhlolwa okuvamile kwezihlungi, amavalvu, namasistimu okugcoba kusiza ukugwema ukuphuka nokuqinisekisa ukusebenza okungaguquki.

Ingabe uchungechunge lwe-JT lungaphatha osayizi bebhodlela abahlukene nemiklamo?

Yebo! Uchungechunge lwe-JT luzivumelanisa nosayizi abahlukahlukene bamabhodlela, ukusuka kumalitha angama-20 kuye kwangama-50, futhi lusekela imiklamo ehlukahlukene ngokuhambisana nesikhunta esivumelana nezimo kanye nesistimu yokulawula ethuthukisiwe.

Ithiphu: Hlala ubheka imanuwali yomshini ukuze uthole amashejuli athile okulungisa kanye nemihlahlandlela yokusebenza.

Isikhathi sokuthumela: May-26-2025